Catalog excerpts

Vacuum Dynamics The Flexible Centralized Vacuum System for Chip Removal Features: • Vacuum Dynamics Systems can be automated to service several machines. Now it is easy to clean up machining centers, part pallets and workholding fixtures with a Mayfran Vacuum Dynamics® System. • Has manual stations to service multiple clean-up A pnuematic chip removal system, Mayfran Vacuum Dynamics handles wet or dry cast iron, ferrous and non-ferrous chips and all sorts of small turnings. And, it has the pneumatic power it takes to move chips over long distances. • Flexibility of the system lets it conform to any plant layout without costly relocation of machinery. P.O. Box 43038 Tel: (440) 461-4100 Cleveland, OH 44143-0038 Fax: (440) 461-0147 Internet: www.mayfran.com E-mail: info@mayfran.com Vacuum Dynamics is a registered trademark of Mayfran Interrnational Vacuum Dynamics Ideal for FMS/Pallet Systems

Open the catalog to page 1

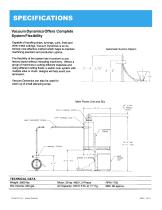

Vacuum Dynamics Offers Complete System Flexibility Capable of handling chips, turnings, curls, fines and other metal cuttings, Vacuum Dynamics is an ex- tremely cost-effective method which helps to maintain machining precision and production uptime. The flexibility of the system lets it conform to any factory layout without relocating machinery. Where a group of machines is cutting different materials and using different cutting fluids, a switch-over system with multiple silos or chute designs will help avoid con- Vacuum Dynamics can also be used for clean-up of small stamping scrap....

Open the catalog to page 2

A sophisticated self-cleaning filtration unit is built into the top of the sito. As the incoming swarf enters the silo a cyclone effect is created. Swart and cutting fluid are centrifuged against the silo walls, the fluid to drain into the collecting tray below. Finally the swarf particles drop out of the cylone and the return air passes up the centre through 8 filter elements. Each element in turn is cleaned automatically by a short blast of compressed air every 30 seconds, leaving the return air 99.99% clean and with minimum down-time for service. INCOMING SWARF The power-pack and silo...

Open the catalog to page 3All MAYFRAN International catalogs and technical brochures

-

Cleansweep-RM

2 Pages

-

MAYFRAN CHIP CONVEYORS

1 Pages

-

Power Trof II

2 Pages

-

Magentic Roller Separators

2 Pages

-

CleanSweep-RM Chip Conveyors

2 Pages

-

Pneumatic Chip Conveyor

12 Pages

-

Chip_Wringers_(Centrifuges)

4 Pages

-

Chip_Shredders_(Crushers)

4 Pages

-

ChipTote Conveyor

2 Pages

-

Shuffle Drive System

6 Pages

-

Viavent Overead Pump System

8 Pages

-

Central Coolant Filtration

8 Pages

-

FastPac Briquetter

2 Pages

-

VacufilterVseries

4 Pages

-

VacuFilterEseries

4 Pages

-

MMF Filter

2 Pages

-

Hydrostatic Paper Filter-HPF

4 Pages

-

MagSep System

2 Pages

-

ConSep Model 2000

6 Pages

-

Chip Wringers / Centrifuges

4 Pages

-

Chip Shredders / Crushers

4 Pages

Archived catalogs

-

Guide to Chip Types

1 Pages