Website:

MAXDRILL ROCK TOOLS CO., LTD

Website:

MAXDRILL ROCK TOOLS CO., LTD

Group: KEMAI MACHINERY & EQUIPMENT CO.,LTD

Catalog excerpts

Concentric Casing Systems Application Range: It is recommended to drill in rock formation where contains some ovals and fractures. Design Principles: The stable and reliable working performance and the less vibration of drill rig. Different Structures: Concentric system with ring bits, wing and blocks. A: Discharge Head B: Drill Rod C: Guide Sleeve D: DTH Hammer E: Casing Tube F: Pilot Bit G: Casing Shoe H: R

Open the catalog to page 1

With Ring Bits 1. When drilling starts, the pilot bit drive the ring bit down to the hole, followed the casing shoe and casing tube. 2.At the bedrock, start Reverse circulation of tools and pull the pilot bit from the drill hole leaving the ring bit in the hole. 3. Pour the concrete or do the next constructions work. 1.After the drilling starts, the pilot bit drive the ring bit down to the hole, followed the casing shoe and casing tube. 2. At the bedrock, start Reverse 3. Pull the casing tube out with the circulation of tools and pull the pilot ring bit and at the same time pour...

Open the catalog to page 2

Thickness Range Hammer Type Drill Pipe Range

Open the catalog to page 3

MAXDRILL ROCK TOOLS CO., LTD www.max-drilling.com MAXDRILL

Open the catalog to page 4

With Wings Guide Device Operation Procedure 1. The wings swing out soon after the drilling start and the ream drives the casing shoes and tubes in the drill hole. 2. After completed the drilling process in overburden rock formation, as soon as the reverse drilling process start the wings will get closed, so the drilling tools can be pull back from the drill hole. 3. Follow the next drilling process. Thickness Range Hammer Type Drill Pipes

Open the catalog to page 5

MAXDRILL ROCK TOOLS CO., LTD www.max-drilling.com With Blocks Assembly Operation Procedure 1. At the start of drilling, the blocks slides down through the grooves on pilot bit, and the ream drives the casing shoes and tubes into the drill hole. 2. After complete the drilling process in overburden rock formations, raise the drilling tools then the blocks will get closed through the grooves, the drilling tools can be pulled out from the drill hole. 3. Next construction can be followed.

Open the catalog to page 6All MAXDRILL ROCK TOOLS CO. catalogs and technical brochures

-

SELF-DRILLING ANCHOR SYSTEM

13 Pages

-

TAPHOLE DRILL BIT

4 Pages

-

TAPHOLE DRILL ROD

5 Pages

-

Y20 HAND-HELD ROCK DRILL

2 Pages

-

YT28 JACKLEG DRILL

2 Pages

-

BREAKER STEEL

1 Pages

-

12° TAPERED DRILLING TOOLS

6 Pages

-

DOWN THE HOLE BIT

4 Pages

-

6° TAPERED DRILLING TOOLS

6 Pages

-

7° TAPERED DRILLING TOOLS

5 Pages

-

DTH HAMMER

74 Pages

-

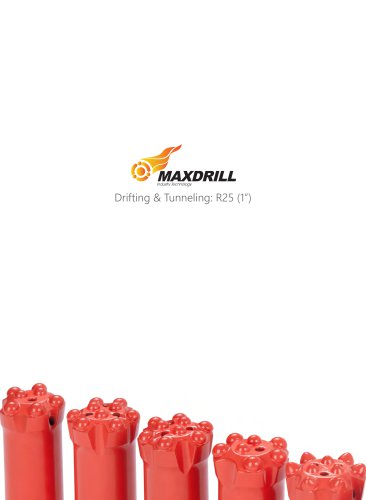

Drifting & tunneling

20 Pages

-

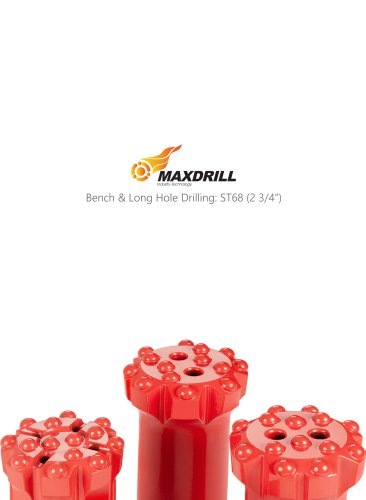

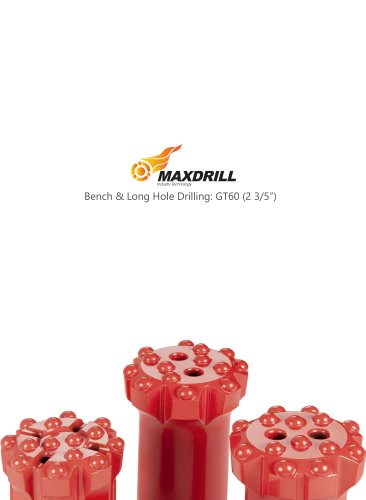

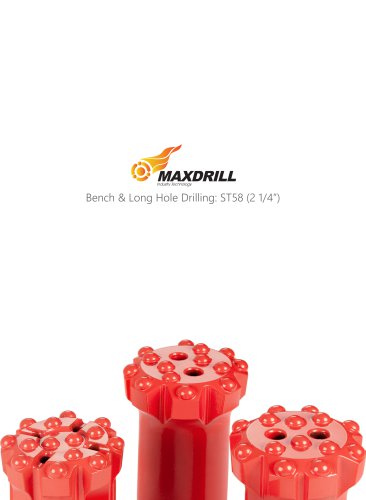

TopHammer-drilling-tools

63 Pages

-

integral drill steel

1 Pages

-

6° taper drill rod and bit

2 Pages

-

12 inch DTH hammer and bit

20 Pages

-

10 inch DTH hammer and bit

19 Pages

-

8 inch DTH hammer and bit

22 Pages

-

5 inch DTH hammer and bit

23 Pages

-

3 inch DTH hammer and bit

17 Pages

-

Down the hole drill bit--QL60

22 Pages

-

Rotary and cutting teeth

5 Pages

-

Wear parts

9 Pages

-

Engineering Cutter Tools

13 Pages

-

Concentric

6 Pages

-

Y24 Hand-Held Rock Drill

2 Pages

-

Maxdrill Break steel

1 Pages

-

Maxdrill Hand splitter

2 Pages

-

Maxdrill Plug Hole Rod

1 Pages

-

Maxdrill Rock Drills Y28

3 Pages

-

Maxdrill Rock Drills Y24

3 Pages

-

Maxdrill Rock Drills Y20

3 Pages

-

Maxdrill DTH drill pipes

4 Pages

-

Maxdrill Down The Hole Hammer

54 Pages

-

DTH Drill Pipes

4 Pages

-

Integral Drill Rod

5 Pages