Catalog excerpts

Maurer Magnetic AG – white paper Low-level demagnetization as preparation process for shaping of metal powder parts Marek Rohner Head of Technology Maurer Magnetic AG 8627 Grüningen Switzerland

Open the catalog to page 1

Compaction of metal powder Maurer Magnetic AG, your specialist for: •Industrial demagnetizing machines •Instruments for measuring magnetic fields •Degaussing services •Troubleshooting in the field of magnetism •Permanent magnets and magnetic systems

Open the catalog to page 2

Compaction of metal powder Abstract Metal powder pressed parts are mainly used in mass production for the automotive industry. Short production times, precisely controlled material properties, and minimum rework of the parts make this process particularly interesting. An important production cost factor are the punches and dies, which are usually made of sintered tungsten carbides and often provided with wear resistant coatings. These tools are subject to strong mechanical wear, and hence have a limited life. Ferromagnetic sintered tungsten carbides (STC) show, in conjunction with the...

Open the catalog to page 3

Compaction of metal powder Powder sticking on edges Powder density variations Powder sticking on edges Powder beards Behavior of the ferromagnetic powder on magnetic dies and punches Magnetic field lines take the path of minimum resistance. With a relative magnetic permeability of µr~1, air represents for magnetic field lines a high resistance. Ferromagnetic steel conducts magnetic fields much better, due to values of µr=200…1000. Magnetic field lines have always a closed path. They run as far as possible in the steel, due to the low magnetic resistance, and return at the end, typically on...

Open the catalog to page 4

Compaction of metal powder Carbide punch, below 2A/cm Punch and die, inside air gap, below 2A/cm Behavior of the metal powder in perfectly demagnetized dies and punches The demagnetization of the carbide metal dies and punches shown here was performed using a degaussing pulse sequence of high power density, characterized by very high field strengths, and a field completely enveloping the part. The high field strength ensures that all magnetic moments of the hard metal are reversed, and the enveloping field volume guarantees a uniform flux over the entire piece. With this method, on all...

Open the catalog to page 5

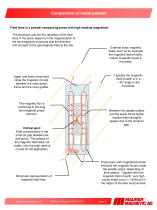

Compaction of metal powder Field lines in a powder compacting press with high residual magnetism The directions and the flux densities of the field lines in the press depend on the magnetization of the ferromagnetic structures and the direction and strength of the geomagnetic field at the site. External static magnetic fields, such as for example the magnetic field of earth, induce magnetic fluxes in the press. Typically the magnetic field of earth is in a ~ 45° angle to the horizontal. Upper and lower cross bars close the magnetic circuits between the outer press frame and the inner...

Open the catalog to page 6

Compaction of metal powder Field lines in a demagnetized powder compacting press The directions and the flux densities of the field lines in the press depend on the magnetization of the ferromagnetic structures and the direction and strength of the geomagnetic field at the site. External static magnetic fields. The press columns of the press frame are shielding the inside from the magnetic field of earth. The internal adapter is therefore only marginally affected by ambient magnetic fields. The residual magnetic stray fluxes are greatly reduced between the adapter plates and the press frame...

Open the catalog to page 7

Compaction of metal powder Demagnetization of press components and fully assembled powder presses The main structures of powder presses are made of ferromagnetic steel. Powder compacting presses over 250 tons of pressure force require heavy steel parts with massive cross sections to handle the forces. The successful demagnetization of such parts can be achieved only with high performance degaussing devices. The press components are generally produced by several sub-processes, done by sub contractors, and the parts are also transported several times. It is hard to exclude that such parts are...

Open the catalog to page 8

Compaction of metal powder Gain competitive advantage through your own know-how Process security in the mass production of ferromagnetic sintered parts has made a big step ahead through perfectly demagnetized powder presses and tools. Companies that are active in powder metallurgy must any time be able to perform required in-house demagnetizations on short notice. Only by this, a consistent high production and quality level without prolonged interruption and without dependence on external service providers is maintained. The investment cost of the demagnetizing systems is paid back after a...

Open the catalog to page 9

Compaction of metal powder Deployment of the demagnetizing method within the manufacturing process flow The three magnetically critical components of a powder press, tooling, adapter, and press frame, are demagnetized according to the scheme presented below. The following priorities have to be taken into account: 1. Tooling 2. Adapter 3. Press frame

Open the catalog to page 10All Maurer Magnetic catalogs and technical brochures

-

Loop Demagnetizers CT

2 Pages

-

Plate Demagnetizers MM PE

4 Pages

-

Magnetic field viewer

2 Pages

-

Teslameter M-Test Mk4

2 Pages

-

Magnetizer MPA 400

1 Pages

-

Zero-Gauss Chamber

2 Pages

-

General brochure

4 Pages