Catalog excerpts

PROCESSING TECHNOLOGIES FOR COOKING SMOKING • MATURING • DRYING •AGING Semi-continuous batch systems (KCS) Advantages “Inline” production: The production process is performed inline with the semicontinuous loading system, i. e. there is no processing delay between filling and packaging. Use: Each of the process chambers are separated by an intermediate transfer zone (hinged or vertical lifting doors). A system may consist of two or more zones. 100% separation between low and high risk areas: The airtight transfer zone between the entry and exit sides allows the separation of production and packaging areas (“low-risk“, “high-risk“). Possible processing: · drying / smoking / cooking transferred to intensive cooling downstream · cooking transferred to intensive cooling downstream · other combinations on request Integration: The system can be integrated into the production area due to upstream and downstream automation. Floor transport/ roller or overhead rail conveyor: An electric drive system ensures smooth transportation. Maurer-Atmos Middleby GmbH · Kindlebildstrasse 100 · 78479 Reichenau · German

Open the catalog to page 1

Semi-continuous batch systems Example with floor conveyor installations (racks or smoking carts) low-risk side 1st process chamber (smoking, cooking, etc.) 2nd process chamber (intensive cooling, etc.) high-risk side transfer zone, hinged or vertical lifting door Example with suspended racks low-risk side 1st process chamber (smoking, cooking, etc.) 2nd process chamber (intensive cooling, etc.) high-risk side transfer zone, hinged or vertical lifting door buffer Cabinet dimensions (incl. extension) (cm) length with hinged doors in transfer zone Minimum ceiling height for hinged doors (cm)...

Open the catalog to page 2All Maurer-atmos catalogs and technical brochures

-

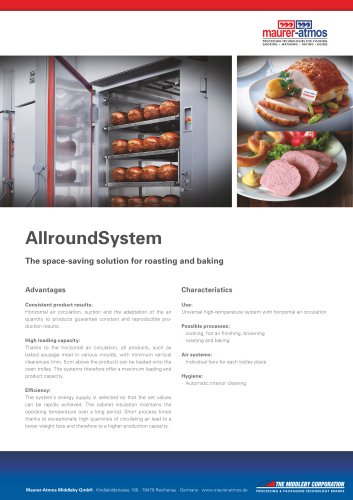

AllroundSystem ASR

2 Pages

-

Cooking Kettles ( FK )

2 Pages

-

AllroundSystem AFR

2 Pages

-

ProfitLine PRR

2 Pages

-

ProfitLine PFR

2 Pages

-

Universal-circulation system

2 Pages

-

ProfitLine PK

2 Pages

-

AllroundSystem ARQ

2 Pages

-

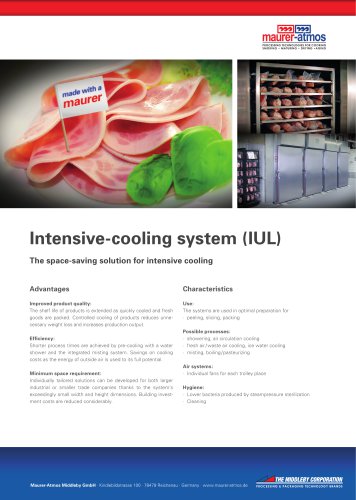

Intensive-cooling system

2 Pages

-

ProfitLine PUR

2 Pages

-

Continuous systems (CONTI)

2 Pages

-

Industrial thawing systems

2 Pages

-

Internal smoke generators

2 Pages

-

Cleaning systems

1 Pages

-

Remote-control-App

2 Pages

-

Smoke house - ASR

2 Pages

Archived catalogs

-

External smoke generators

2 Pages