Catalog excerpts

PROCESSING TECHNOLOGIES FOR COOKING SMOKING • MATURING • DRYING •AGING Environment and energy efficiency systems (ECO) Re-circulated ice water system Environmentally friendly and resource-saving production: Energy savings and therefore reduced production costs due to the use of a thermal afterburning system with heat recovery as well as re-circulated ice water cooling. Economic concept for intensive cooling: Enormous reduction of fresh water consumption. Can be used for all products – packaged, in sterile casing and in various moulds. Process time reduction: In the case of re-circulated ice water cooling, the products are cooled rapidly by maximum heat transfer. This decreases weight losses, reduces bacterial growth, extends shelf life and improves colouring. Circulation cycle system comprised of: · Circulation pumps · Heat exchanger · Filter systems · Dosers (optional) · UV-sterilization (optional) Gas-heated thermal afterburning system with heat recovery: Optimized energy recovery by using residual heat. The recovered energy can be used in various ways: · Warm water generation · Heating of a hot pressurized water cycle in order to provide indirect system heating via heat exchangers Exhaust gas cleaning and heat recovery comprised of: · Thermal afterburning system · A heat exchanger for hot pressurized water (optional) · Circulation pumps (optional) · Pipes Maurer-Atmos Middleby GmbH · Kindlebildstrasse 100 · 78479 Reichenau · Germany · www.maurer-atmos.de

Open the catalog to page 1All Maurer-atmos catalogs and technical brochures

-

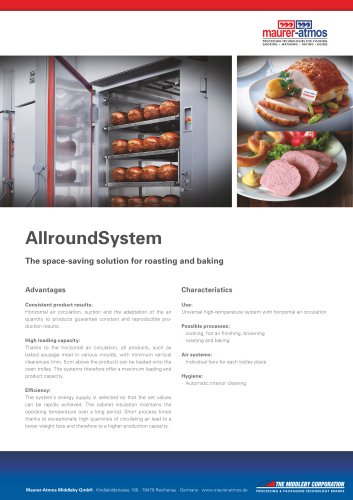

AllroundSystem ASR

2 Pages

-

Cooking Kettles ( FK )

2 Pages

-

AllroundSystem AFR

2 Pages

-

ProfitLine PRR

2 Pages

-

ProfitLine PFR

2 Pages

-

Universal-circulation system

2 Pages

-

ProfitLine PK

2 Pages

-

AllroundSystem ARQ

2 Pages

-

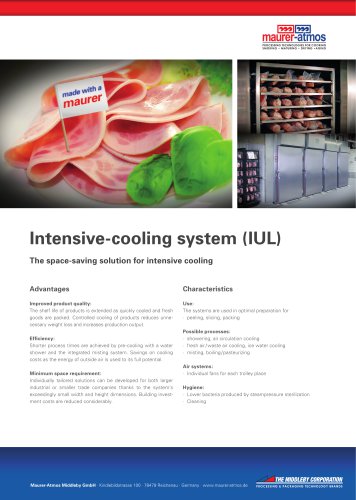

Intensive-cooling system

2 Pages

-

ProfitLine PUR

2 Pages

-

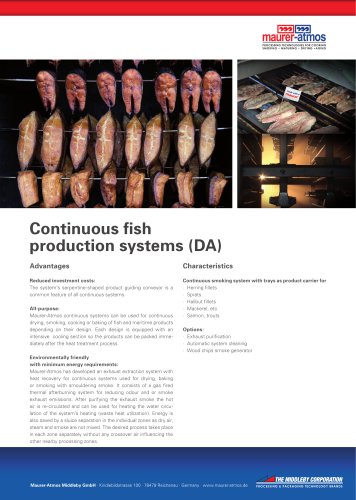

Continuous systems (CONTI)

2 Pages

-

Industrial thawing systems

2 Pages

-

Internal smoke generators

2 Pages

-

Cleaning systems

1 Pages

-

Remote-control-App

2 Pages

-

Smoke house - ASR

2 Pages

Archived catalogs

-

External smoke generators

2 Pages