Catalog excerpts

Vibration Test Stand VTS · Automatic Determination of Resonance Frequencies Solutions for Turbine and Engine Blades Overview Maul-Theet offers different configurations to determine resonance frequencies of any type of blade. Depending on the application, different types of excitation and vibration sensors are offered. Inputs for pressure and temperature are available. VTS with customers own hydraulic User Management Work Order Management Blade Types Blade Measurement Data Master Blades This solutions includes all components to determine the resonance frequencies (Impact hammer, vibration sensor, DAQ) and the PC with the software. It works independent from the clamping device or excitation. If the component is clamped the vibration measurements and the resonance frequency determination can be carried out. The data can be saved and reports can be generated. Clamping Force Determination VTS Manual Hydraulic Control Automated Reporting VTS Controller with Pressure and Temperature Input Hydraulic Unit PLC Controlled Hydraulic Unit This solution includes a manual controlled hydraulic unit. It is integrated in the test rig made out of aluminium profiles which also may house the clamping unit. The design of the test rig can be adapted to the customers application. The clamping force is detected by the VTS Controller and displayed in the VTS Software. If the clamping force is out of range the VTS Software automatically blocks the frequency measurement. The clamping force is set via toggle switch, which sets the pressure in the cylinder. Clamping Block with Adapter

Open the catalog to page 1

VTS PLC Controlled Hydraulic This solution has a hydraulic unit with integrated PLC. The PLC controls the proportional valves to start, bias and controls the clamping forces during the vibration measurement. The pressure accumulators ensure that the clamping forces will stay stable during experimental measurements, which also last longer than 20 min. In the case of acoustic vibration measurements no pump operation interferes. Depending of the hydraulic cylinder used, the PLC controlled hydraulic enables clamping forces of up to 650 kN.

Open the catalog to page 2

Vibration measurement Commercially available sensors are offered for measuring the resonance frequency of the blades. · Microphone: Inexpensive and non-contact, influenced by ambient noise · Laser Doppler Vibrometer: Non-contact, no influence by ambient noise · Accelerometer: No influence by ambient noise. Influence by sensor mass and cable (only suitable for big blades) The VTS Software has algorithms to improve peak picking for resonance detection in noisy spectra. A change in the actual blade frequency due to the temperature can be corrected with the help of the integrated compensation...

Open the catalog to page 3All MAUL-THEET GmbH catalogs and technical brochures

-

vRotorModal

2 Pages

-

FDT

2 Pages

-

DTS

2 Pages

-

ATS

2 Pages

-

vSpeedBox

2 Pages

-

vModal

2 Pages

-

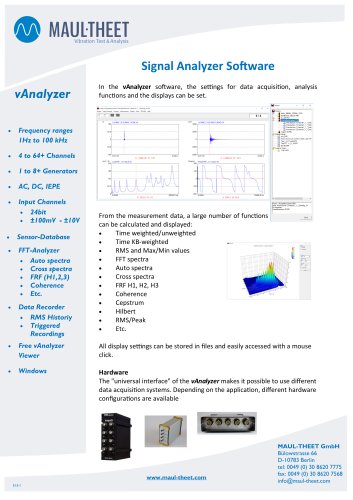

vAnalyzer

2 Pages

-

vMonitor

2 Pages

-

vImpact-63

2 Pages

-

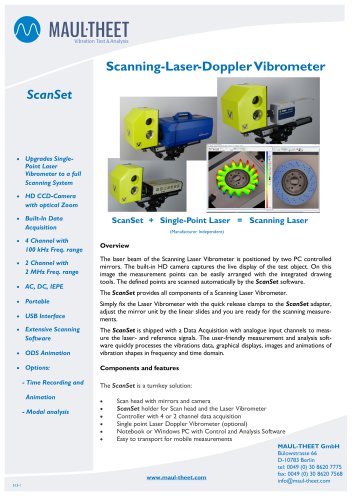

ScanSet

2 Pages