Catalog excerpts

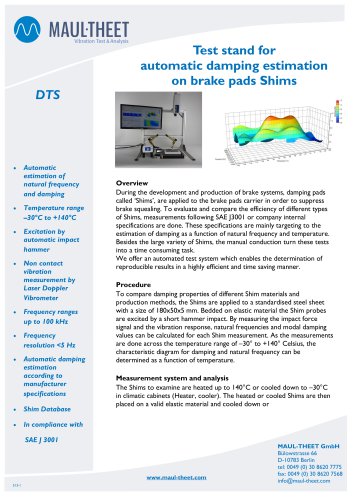

Automatic estimation of natural frequency and damping Excitation by automatic impact hammer Non contact vibration measurement by Laser Doppler Vibrometer Automatic damping estimation according to manufacturer specifications Shim Database Test stand for automatic damping estimation on brake pads Shims Overview During the development and production of brake systems, damping pads called ‘Shims’, are applied to the brake pads carrier in order to suppress brake squealing. To evaluate and compare the efficiency of different types of Shims, measurements following SAE J3001 or company internal specifications are done. These specifications are mainly targeting to the estimation of damping as a function of natural frequency and temperature. Besides the large variety of Shims, the manual conduction turn these tests into a time consuming task. We offer an automated test system which enables the determination of reproducible results in a highly efficient and time saving manner. Procedure To compare damping properties of different Shim materials and production methods, the Shims are applied to a standardised steel sheet with a size of 180x50x5 mm. Bedded on elastic material the Shim probes are excited by a short hammer impact. By measuring the impact force signal and the vibration response, natural frequencies and modal damping values can be calculated for each Shim measurement. As the measurements are done across the temperature range of –30° to +140° Celsius, the characteristic diagram for damping and natural frequency can be determined as a function of temperature. Measurement system and analysis The Shims to examine are heated up to 140°C or cooled down to –30°C in climatic cabinets (Heater, cooler). The heated or cooled Shims are then placed on a valid elastic material and cooled down or

Open the catalog to page 1

warmed up to room temperature. While heating up/cooling down the temperature is continuously measured by a non contact temperature sensor. Reaching a predefined temperature (f.e. -30°C to 140°C in steps of 2°C) impact excitations to the Shim probe by the automatic hammer are triggered. The hammer includes a force cell at the hammer tip that measures the force series of the excitation. The vibration response of the Shim probe is measured by a Laser Doppler Vibrometer. This non contact measurement technique ensures that no mass load by a sensor distorts the results, like it happens when...

Open the catalog to page 2All MAUL-THEET GmbH catalogs and technical brochures

-

vRotorModal

2 Pages

-

FDT

2 Pages

-

ATS

2 Pages

-

VTS

3 Pages

-

vSpeedBox

2 Pages

-

vModal

2 Pages

-

vAnalyzer

2 Pages

-

vMonitor

2 Pages

-

vImpact-63

2 Pages

-

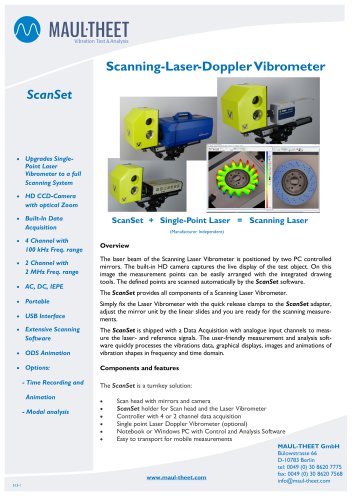

ScanSet

2 Pages