Catalog excerpts

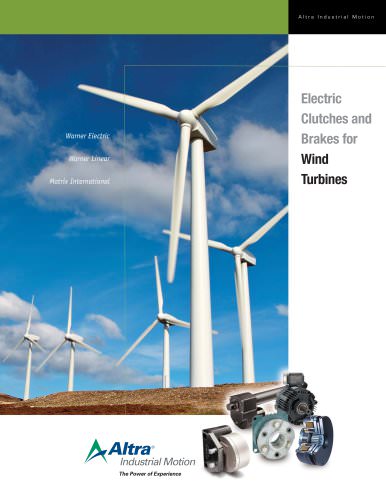

Standard Clutches and Brakes

Open the catalog to page 1

With over 75 years in the design and manufacture of standard, as well as customized brakes and clutches, Matrix products meet the needs of the power transmission industry through a flexible approach to application and sales support. Early involvment in design processes by the Matrix engineering team holds the key to building customer confidence — resulting in custom solutions which match application requirements. sales and technical support in over 70 countries around the world. Matrix support extends well beyond sales and technical applications with manufacturing capability in North...

Open the catalog to page 2

Quality Matrix Quality Systems are accredited to ISO 9000:2000 standards ensuring that product design and development, manufacturing, and service are of the highest standard. Matrix is in the process of attaining ISO 14001 environmental standards while minimizing our carbon footprint and working toward sustainable operations throughout our supply chain. Our refined manufacturing processes and quality supply chain partners enable us to provide cost-effective products that continually meet or exceed the expectations of the market. Testing & Research We offer the capability to quickly produce...

Open the catalog to page 3

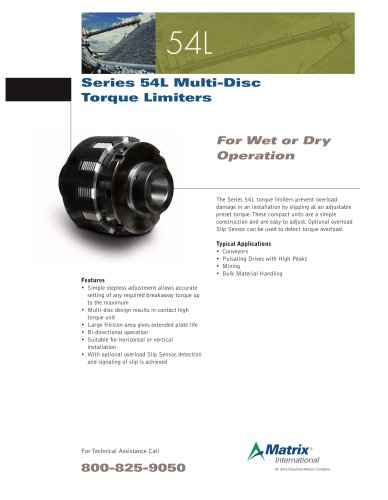

Features • Clutch requires no adjustment • Shielded bearings need no lubrication in service • Stationary cylinder allows simple supply connection • Torques can be varied by regulating supply pressure • Engagement speed controlled by varying pressure supply flow rate • Large friction area gives extended plate life • Individual plate separation ensures low drag torque • Multi-disc design results in compact high torque clutch • No axial thrusts transmitted to adjacent components • All concentricities controlled within the clutch simplifying installation • Pilot mount can be used to attach...

Open the catalog to page 4

Rated Static Torque Rated Dynamic Torque Pressure to Overcome Release Springs Drag Torque Maximum Energy per Engagement Maximum Energy per Hour Maximum Speed Number of holes Size Depth PCD Fixing Holes

Open the catalog to page 5

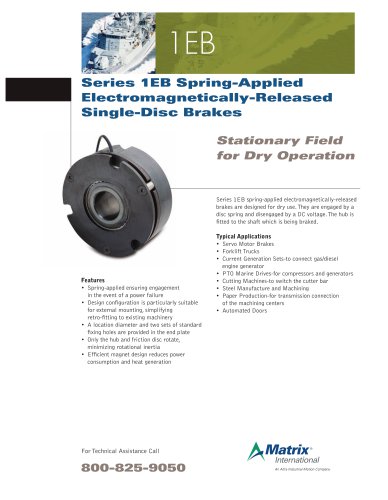

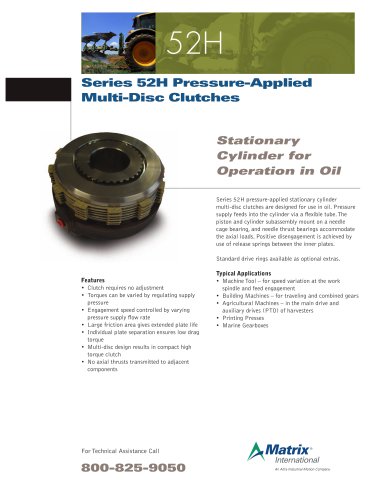

Multi-Disc Clutches Series 52H Series 52H Pressure Applied Multi-Disc Clutches Stationary Cylinder for Operation in Oil Features • Clutch requires no adjustment Series 52H pressure-applied stationary cylinder multidisc clutches are designed for use in oil. Pressure supply feeds into the cylinder via a flexible tube. The piston and cylinder subassembly mount on a needle cage bearing, and needle thrust bearings accommodate the axial loads. Positive disengagement is achieved by use of release springs between the inner plates. Standard drive rings available as optional extras. • Torques can be...

Open the catalog to page 6

Standard Bores (H7) Keyways to I.S.O. 773 B.S. 4235:1972 Pt. 1 D.I.N. 6885:1968 Pt. 1; NF.E22-175 (Bores other than standard can be obtained by special order) Minimum Bore M Maximum Engaged N Disengaged P Q Nominal S Nominal Drive Ring 33 46 59 • More models available

Open the catalog to page 7

Features • Clutch does not require adjustment • Torques can be varied by regulating supply pressure • Bearing-free design eliminates bearing life considerations • Speed of engagement can be controlled by varying pressure supply flow rate • Individual plate separation ensures low drag torque • Large friction area gives extended plate life • Multi-disc design results in compact high torque clutch • No axial thrust transmitted to adjacent components Series 66H-02 Pressure Applied Multi-Disc Clutches Rotating Cylinder for Operation in Oil Series 66H-02 pressure-applied rotating cylinder...

Open the catalog to page 8

Standard Bores (H7) Keyways to I.S.O. 773 B.S. 4235:1972 Pt. 1 45 80 150 (For bores other than specified please consult our Engineering Department) Diameters (all dimensions in mm) A 125 220 355 Diameter of Feed Holes to plates 6.4 8.0 10.0 Drive Ring • More models available

Open the catalog to page 9

Features • Tooth clutch gives positive drive with no slip • Shielded bearings need no lubrication in service • Stationary cylinder allows simple supply connection • Spring disengagement results in no drag torque other than the rolling resistance of the drive flange/hub bearing • Standard fixing holes provided in the drive flange • No axial thrusts transmitted to adjacent components Series 55H-P Advantages • All concentricities are controlled within the clutch simplifying installation • Pilot mount can be used to attach pulleys, sprockets and other drive components simplifying assembly...

Open the catalog to page 10

Fixing Holes Number of holes 33366666 Fixing Holes Number of holes 333666686

Open the catalog to page 11

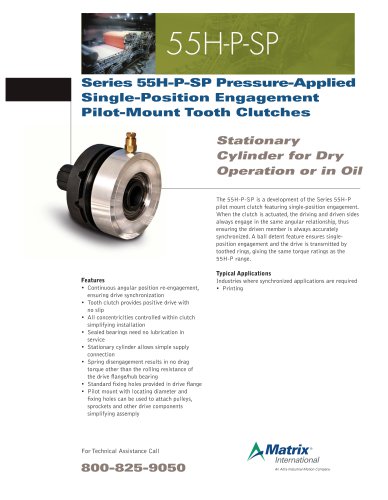

Series 55H-P-SP Features • Continuous angular position re-engagement, ensuring drive synchronization • Tooth clutch provides positive drive with no slip • All concentricities controlled within clutch simplifying installation • Sealed bearings need no lubrication in service • Stationary cylinder allows simple supply connection • Spring disengagement results in no drag torque other than the rolling resistance of the drive flange/hub bearing • Standard fixing holes provided in drive flange • Pilot mount with locating diameter and fixing holes can be used to attach pulleys, sprockets and other...

Open the catalog to page 12

Tooth Clutches Standard Bores (H7) Keyways to I.S.O. 773 B.S. 4235:1972 Pt. 1 D.I.N. 6885:1968 Pt. 1; NF.E22-175 (Bores other than standard can be obtained by special order) Minimum Bore Fixing Holes

Open the catalog to page 13

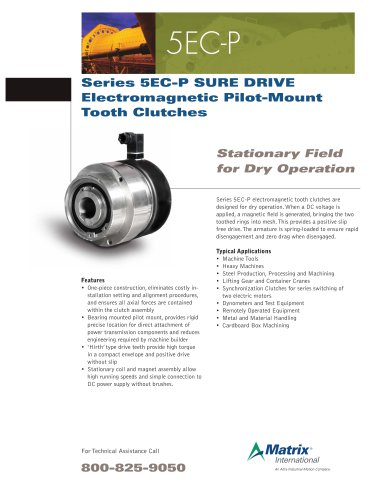

Tooth Clutches Series 5EC-P Series 5EC-P Sure Drive Electromagnetic Pilot-Mount Tooth Clutches Stationary Field for Dry Operation Features • One-piece construction, eliminates costly installation setting and alignment procedures, and ensures all axial forces are contained within the clutch assembly • Bearing mounted pilot mount, provides rigid precise location for direct attachment of power transmission components and reduces engineering required by machine builder • ‘Hirth’ type drive teeth provide high torque in a compact envelope and positive drive without slip • Stationary coil and...

Open the catalog to page 14All Matrix International catalogs and technical brochures

-

ALTRA MOTION

2 Pages

-

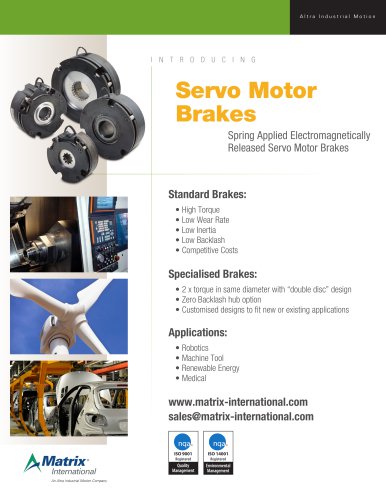

Servo Motor Brakes (SMB)

8 Pages

-

Servo Motor Brakes

2 Pages

-

Servo Motor Brakes

4 Pages

-

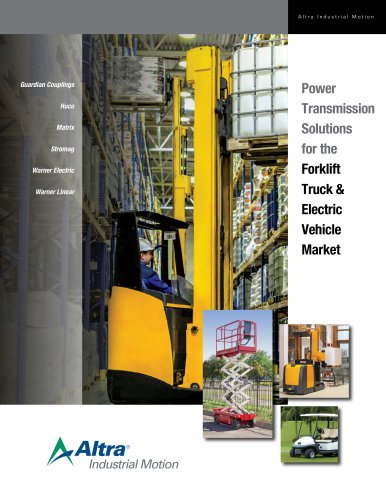

Forklift Truck Brakes

15 Pages