Catalog excerpts

FOOD PROCESSING MACHINERY PRODUCTION LINES PRODUCTIVITY AND RELIABILITY TAILORED TO YOUR PRODUCT

Open the catalog to page 1

OF THE LASKA PRODUCTION LINES The demand for automatic production lines is rising sharply worldwide. Production lines are used for the following products: fine sausage meat, cooked or raw sausage, minced meat and burgers, as well as convenience products. This unbroken trend towards production lines is driven by the needs to constantly reduce production costs (while keeping quality constant), to standardize the processing of raw materials, and to ensure traceability. PROFESSIONAL ENGINEERING Together with you we‘ll compose the optimum combination of machines for your needs from among our...

Open the catalog to page 2

HIGH SAFETY TRANSPARENT PROCEDURES ›› ractice-oriented safety installations P for optimum working safety ›› tandardization of raw materials and S production sequences used ›› Clearly arranged control system ›› asy handling, e.g. via LASKA E programme control „PMS“ (Production Management System) ›› raceability, when and where and T by whom the goods were processed ›› User-friendly control elements ›› Good accessibility for cleaning ›› olished surfaces for highest possible P cleaning standard LASKA PRODUCTION LINE YOUR BENEFITS AT A GLANCE ROBUST MACHINES ›› igh operating safety due to robust...

Open the catalog to page 3

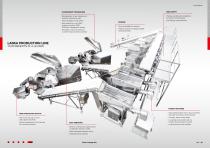

LASKA PRODUCTION LINES MINCED MEAT, BURGER, OR RAW SAUSAGE LINE (EXAMPLE) ›› Raw material is put onto the unpacking table ›› Ingredients can be added via the loading unit ›› aterial is conveyed into the grinder via a M conveyor belt provided with a metal detector ›› fter the mixing cycle the product ready A to portion is conveyed to the filling units ›› fter mincing, the material is conveyed A to the mixers / Angle mixer-grinders Please note that the above description is just an example. The line will be exactly adapted to your needs. BOILED OR COOKING SAUSAGE LINE (EXAMPLE) ›› Raw material...

Open the catalog to page 4

MACHINE TYPES KEY TECHNOLOGY FOR YOUR PRODUCTION LINE ANGLE GRINDERS AND ANGLE MIXER-GRINDERS ›› or processing fresh meat or several frozen meat blocks F simultaneously, depending on the type ›› Hopper size: up to 4500 litres ›› ersion with two worms arranged at an angle for V gentle processing, low heating, and high hourly rate ›› Infinitely variable speed ›› Cleaning ducts for perfectly hygienic cleaning ›› Intermeshing paddle mixing shafts ›› Cleaning ducts for perfectly hygienic cleaning ›› Unloading flap with protective hood ›› any options: vacuum facility, cooking/heating and M...

Open the catalog to page 5

MATERIALS HANDLING EQUIPMENT OPTIMUM ADJUSTMENT FOR YOUR PRODUCTION LINE CONVEYOR BELTS METAL DETECTOR SAUSAGE MEAT HOPPER WITH PUMP ›› Inclined/horizontal/angled conveyor belt ›› Installed at the conveyor belt ›› Special pump for gentle pumping of sausage meat ›› E link conveyors for frozen meat block transport P ›› Detects traces of metals in the base material ›› ipelines with valves for distributing the product P (e.g. to several filling machines) ›› opper with emptying worm filling the connected H sausage meat pump ›› U positive drive conveyor for minced material P and/or sausage meat...

Open the catalog to page 6

CONTROL AND FEEDBACK CONTROL SYSTEMS OVERVIEW AND SAFETY FOR YOUR PRODUCTION LINE LINE CONTROL STATION PMS MIXING PROCESS CONTROL SYSTEMS WEIGHING EQUIPMENT SPICE DOSING (DRY MATERIALS) ›› ontrol station for plant visualization, operation, C and central error display ›› Freely programmable automatic work sequence ›› Various versions depending on application and requirement ›› isplay of the weights of mixed quantities, D added quantities, removed quantities ›› pice dosing via big bag stations and S pneumatic conveyance via pipeline ›› Integral touch screen 12“ ›› reation, storage, and...

Open the catalog to page 7

THAT’S WHAT OUR CUSTOMERS SAY ABOUT THEIR LASKA PRODUCTION LINE COOPERCENTRAL AURORA ALIMENTOS BRAZIL DEKAMARKT NETHERLANDS JOSEF WERNKE VERSANDSCHLACHTEREI GMBH GERMANY „We are using the equipment brand LASKA in the industrialization of hamburger since 2011. This is a very good technology with robust equipment that meets the needs of the industrial process, providing good productivity, easy cleaning and operational safety. „When we were faced with the challenge to double our production within half a year, we opted for machines by LASKA. What was important to us, was both the quality and...

Open the catalog to page 8

TRADITION & INNOVATION MORE THAN 130 YEARS OF EXPERIENCE We have more than 130 years experience of supporting our customers in the production of first-class food. LASKA develops and manufactures high-quality specialist machinery that has always enjoyed a reputation for durability and reliability. Our experts work with our customers to develop innovative solutions for the finest meat-processing systems. Our robust and capable machines have proven their worth in a range of other application areas as well. OUR PRODUCT RANGE: ›› Cutters ›› Grinders ›› Frozen meat cutters ›› Emulsifiers ››...

Open the catalog to page 9All Maschinenfabrik LASKA Gesellschaft m.b.H. catalogs and technical brochures

-

Emulsifiers

2 Pages

-

Mixing machines

2 Pages

-

Grinders

2 Pages

-

Cutters

2 Pages

-

Production lines

2 Pages

-

THE NEW ANGLE GRINDERS

8 Pages

-

LASKA Industrial mixers

11 Pages

-

LASKA Industrial grinders

13 Pages

-

Small scale machines

19 Pages

-

FROZEN MEAT CUTTERS

9 Pages

-

EMULSIFIER

9 Pages

-

INDUSTRIAL CUTTERS

11 Pages