Catalog excerpts

INDUSTRIAL GRINDER EXCELLENT CUT QUALITY AT HIGH HOURLY RATE

Open the catalog to page 1

OF THE LASKA GRINDERS For many decades, LASKA has been on the market with various types of grinders for trade and industry. The excellent cut and the robust, low-maintenance design has convinced LASKA customers, who use their grinders to make the following products: ›› Scalded sausage ›› Raw sausage ›› Cooked sausage ›› Pies ›› Various fish products ›› Ground Meat and Hamburger ›› Cheese, butter ›› Fruit and vegetable products ›› Pet food ›› Sweets STRENGTHS AND BENEFITS LASKA grinders are appreciated for their excellent cut, the numerous safety measures, and the perfect cleaning concept....

Open the catalog to page 2

www.laska.at HYGIENE AND SAFETY ELECTRICAL EQUIPMENT ›› leaning ducts provided with special sealings C to ensure perfectly hygienic cleaning ›› ow current consumption due to state-ofL the-art drive and control technology ›› Closed base plate prevents soiling of the machine interior ›› ntegral control cabinet ensures compact I design as well as long service life of electrical components ›› Polished surfaces for highest possible hygienic standard ›› Clearly arranged control system and high operating safety ›› Safety features for optimum working safety LASKA INDUSTRIAL GRINDER YOUR BENEFITS AT...

Open the catalog to page 3

MACHINE TYPES THE VERSATILE LASKA PRODUCT RANGE APPLICATION OF ANGLE GRINDERS APPLICATION OF ANGLE MIXER GRINDERS ›› Holeplate diameters: 160 and/or 200 mm ›› Processing of fresh meat and pre-chopped frozen meat ›› Holeplate diameters: 130, 160 and/or 200 mm ›› For mixing and mincing in one process ›› High-volume filling hopper ›› ngle structure: feed worm over A the entire length of the mixing hopper ›› ixing hopper with 2 intermeshing paddle M mixing shafts for quick and even mixing ›› Feed worm can be drawn out laterally for easy cleaning ›› uring mixing, the feed worm rotates D...

Open the catalog to page 4

CUTTING TOOLS THE OPTIMUM CUTTING SET FOR THE CUSTOMER’S REQUIREMENTS FRESH MEAT CUTTING SET ›› For processing fresh meat of a temperature of up to -4 °C ›› or processing slightly frozen meat F of a temperature of up to -10 °C ›› -part cutting set 5 (pre-cutting plate, knife, holeplate 13 mm, knife, holeplate 8 mm, 5 mm and 3 mm) ›› -part cutting set 5 (pre-cutting plate, knife, holeplate 20 or 13 mm, knife, holeplate 8 or 5 mm) ›› se of 3-part set also possible U (pre-cutting plate, knife, holeplate) ›› se of 3-part set also possible U (pre-cutting plate, knife, holeplate) DESINEWING...

Open the catalog to page 5

FOR YOUR LASKA GRINDER ANGLE STRUCTURE SOLID CONSTRUCTION GENEROUS MAINTENANCE ACCESS ›› aterial is gently taken by the feed worm and M conveyed continuously to the working worm ›› Double sealing between product and drive areas ›› Solid, self-supporting construction ›› Quick and easy maintenance ›› roduct areas in the worm housing are reliably protected P against the penetration of bearing lubricants and/or gear oils ›› No joints, stainless, highly polished ›› Perfect access for all maintenance and servicing work ›› Quick and easy cleaning ›› Built-in control box can be swung out for...

Open the catalog to page 6

FOR YOUR LASKA ANGLE MIXER GRINDER INTERMESHING PADDLE MIXING SHAFTS MIXING HOPPER WITH MIXING PADDLES ›› arge effective area of the mixing shafts L in relation to the effective mixing hopper volume ›› Solid stainless steel design ›› Short mixing time and even mixing ›› Interval switching of mixing shafts during grinding process ensures a continually supplied worm with mixture ›› Particularly suitable for raw sausage and minced meat mixing FEED WORM ›› Plays an active role in the mixing process ›› Perfectly coordinated with the supply of material to the working worm ›› Fast and complete...

Open the catalog to page 7

FOR YOUR LASKA GRINDER SAFETY COVER FOR CUTTING SET required for CE marking SAFETY SWITCHING RAIL required for CE marking HYDRAULIC LOADING HOIST FOR 200 LITRE STANDARD TRANSPORT TROLLEY INCLINED OR ANGLED BELT CONVEYOR ›› Hinged and electrically interlocked ›› Stainless, hydraulic ›› Modular plastic belt ›› Machine can be switched on only if safety cover is closed ›› achine stops immediately as soon M as the switching rail is actuated ›› Side guides on both sides of the belt, foldable for cleaning ›› Robust, low-maintenance, and durable due to hydraulic drive ›› Complete emptying through...

Open the catalog to page 8

FOR YOUR LASKA ANGLE MIXER GRINDER DIRECT UNLOADING OF MIXING HOPPER Z-SHAPED MIXING ARMS WATER DOSING ›› Via cover or bottom nozzles for various applications ›› fter mixing, the mixed material A can be unloaded from the mixing hopper direct into a standard transport trolley ›› Ideal form for tough products that are to be kneaded ›› Automatic addition of freely selectable amount of water ›› Feed worm runs backwards ›› Ideal for frequent product changes ›› Automatic temperature control ›› Stainless mixing hopper cover, hydraulic or pneumatic ›› Suction flange ›› erfect for mixing in of...

Open the catalog to page 9

THAT’S WHAT OUR CUSTOMERS SAY ABOUT THEIR LASKA GRINDER PERUTNINA PTUJ SLOVENIA DÖLLINGHAREICO GMBH & CO. KG GERMANY “Food industry is technologically a complex and very demanding industrial branch. Thereof we are taking into account and giving a large importance to the reliability of our partners in the implementation of technological equipment. LASKA is in this regard a constant. We are cooperating with LASKA since 1989 and have with its help built our food concern. “Being our long-term supplier, LASKA has become a very important partner assisting us in some production areas. In case of...

Open the catalog to page 10All Maschinenfabrik LASKA Gesellschaft m.b.H. catalogs and technical brochures

-

Emulsifiers

2 Pages

-

Mixing machines

2 Pages

-

Grinders

2 Pages

-

Cutters

2 Pages

-

Production lines

2 Pages

-

THE NEW ANGLE GRINDERS

8 Pages

-

LASKA Production lines

9 Pages

-

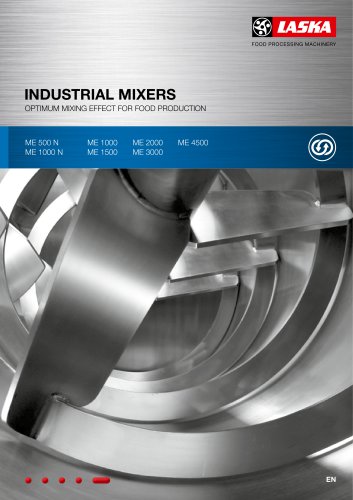

LASKA Industrial mixers

11 Pages

-

Small scale machines

19 Pages

-

FROZEN MEAT CUTTERS

9 Pages

-

EMULSIFIER

9 Pages

-

INDUSTRIAL CUTTERS

11 Pages