Catalog excerpts

FOOD PROCESSING MACHINERY INNOVATIVE SOLUTION FOR THE EFFICIENT MANUFACTURE OF YOUR PRODUCTS

Open the catalog to page 1

OF THE LASKA EMULSIFIERS The most impressive thing about the emulisfier is the unrivalled product quality in this class of emulsifiers permitting production volumes in the medium and high range. The machine produces stable and fine emulsions while being gentle on the material, keeping entrapped air at a minimum, and optimizing energy consumption. The decisive aspect is the innovative electro-hydraulic knife adjustment which ensures high production quality at a very low wear of the cutting set. The elaborate system is successfully applied worldwide for the following applications: ››...

Open the catalog to page 2

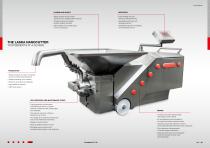

HYGIENE AND SAFETY ›› afety ensured through closed S attachment and integral safety measures ›› Easy handling and user friendly operating elements ›› Polished surfaces for highest possible hygienic standard ›› Swivelling touchscreen with language selection ›› Safe handling due to safety guard in front of cutting set ›› Substantial reduction of operating and maintenance errors THE LASKA NANOCUTTER YOUR BENEFITS AT A GLANCE PRODUCTION ›› table emulsions of maximum fineness S due to innovative knife adjustment ›› Gentle processing of the material ›› Minimum amounts of air entrapped ›› High...

Open the catalog to page 3

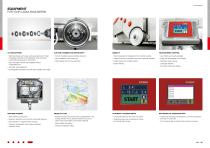

THE PATENTED KNIFE ADJUSTMENT OF THE LASKA EMULSIFIERS INNOVATIVE CONTROL CONCEPT QUALITY THAT TURNS TO ACCOUNT The key element of the NanoCutter is the patented electrohydraulic knife adjustment. The selectable pressure between the rotating cutting knives and the holeplates determines the fineness of the end product. It is controlled and corrected via a hydraulic system hermetically sealed against the product area. To reduce the costs for wear parts such as knives and holeplates, the NanoCutter keeps the contact force as low as possible at all times, thus clearly reducing wear. This means...

Open the catalog to page 4

FOR YOUR LASKA EMULSIFIERS CUTTING SYSTEM CUTTING CHAMBER AND DRIVE SHAFT TOUCHSCREEN CONTROL ›› ptimized design and unique cutting set geometry for high O throughput and optimum emulsification while ensuring a cutting effect going easy on the product ›› Smooth installation space facilitates cleaning ›› Electrical equipment integrated in the machine housing ›› User-friendly and clearly arranged ›› Easy installation of the cutting set ›› Flexible and easy combination with other machines possible ›› Large and easily legible colour display ›› Best hygiene and error-free operation ›› Mobile...

Open the catalog to page 5

FOR YOUR LASKA EMULSIFIER HOLEPLATES AND CUTTING KNIVES ›› oleplates: with hole diameter 0.8 – 8 mm H (standard: 1.2 / 2 / 3 mm) ›› Removes smallest metallic abrasion completely from the product ›› utting knives: with 5 or 3 blades and C exchangeable knife blades ›› Suitable for highly sensitive products such as baby food AUTOMATIC TEMPERATURE CONTROL ›› Desired final temperature of sausage meat freely adjustable ›› emperature permanently controlled via electrically T controlled valves

Open the catalog to page 6

THAT’S WHAT OUR CUSTOMERS SAY ABOUT THEIR LASKA NANOCUTTER ANDRÄ HÖRTNAGL PRODUKTION UND HANDEL GMBH AUSTRIA ZAKŁADY MIĘSNE SILESIA / DUDA POLAND “We use the NanoCutter for manufacturing selected products. The constant product quality has convinced us and our customers. Fineness, little air entrapped, and a regular texture are the ingredients for our products “For Smart Eaters”. „Before deciding for the LASKA NanoCutter we tested a number of other different machines currently on the market from the competition in our works. Until this time we were using a large-scale throughput machine from...

Open the catalog to page 7

TECHNICAL DATA PERFORMANCE LIST PERFORMANCE CHARACTERISTICS TYPE Connected load Operating noise Hopper volume Available holeplate bore diameters Reduced motor output Starting reactor "soft start" Automatic regulation of discharge temperature Special voltage Control system Fuse Feed pipe cross section SEAWORTHY CASE* * depending on type of transport Statistical value; the actual values for your product will be established in a test run on reques Micro process control Technical data are subject to change.

Open the catalog to page 8

TRADITION & INNOVATION MORE THAN 130 YEARS OF EXPERIENCE We have more than 130 years experience of supporting our customers in the production of first-class food. LASKA develops and manufactures high-quality specialist machinery that has always enjoyed a reputation for durability and reliability. Our experts work with our customers to develop innovative solutions for the finest meat-processing systems. Our robust and capable machines have proven their worth in a range of other application areas as well. OUR PRODUCT RANGE: ›› Cutters ›› Grinders ›› Frozen meat cutters ›› Emulsifiers ››...

Open the catalog to page 9All Maschinenfabrik LASKA Gesellschaft m.b.H. catalogs and technical brochures

-

Emulsifiers

2 Pages

-

Mixing machines

2 Pages

-

Grinders

2 Pages

-

Cutters

2 Pages

-

Production lines

2 Pages

-

THE NEW ANGLE GRINDERS

8 Pages

-

LASKA Production lines

9 Pages

-

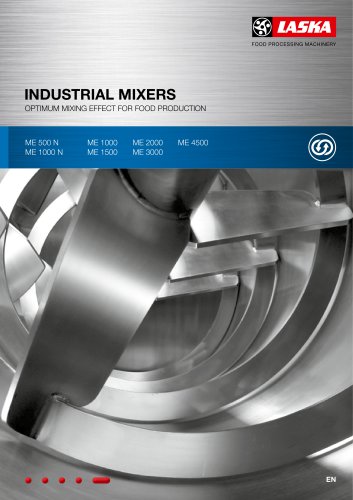

LASKA Industrial mixers

11 Pages

-

LASKA Industrial grinders

13 Pages

-

Small scale machines

19 Pages

-

FROZEN MEAT CUTTERS

9 Pages

-

INDUSTRIAL CUTTERS

11 Pages