Website:

MARKATOR Manfred Borries GmbH

Website:

MARKATOR Manfred Borries GmbH

Catalog excerpts

MARKATOR ® -PRODUct range Conventional marking

Open the catalog to page 1

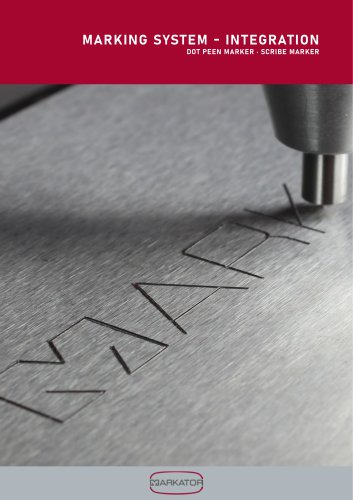

We are experts in durable and economic marking of industrial parts to help eliminate forgery. MARKATOR® have been developing and manufacturing high-quality systems for dot peen and scribe marking for over 25 years. We also produce hand-held and machinery marking tools. We can meet our customers’ needs individually and precisely. Our aim is to achieve highest quality. We attach importance to solid consulting, customer-related development and user-friendly marking systems. We maintain a constant dialogue with our customers and their applications, which helps us to maintain continual...

Open the catalog to page 2

Conventional marking MARKATOR® offers several solutions for the conventional marking of work pieces – from hand marking punches with your own company logo or simple standard machines through to individual, fully automatic special-purpose machines. Impact marking machines, pressure marking machines, roll marking machines, hot stamp machines and stamp tools offer many possibilities to mark work pieces of all kinds. Impact marking machines The conventional marking systems of MARKATOR® are particularly suitable for unchanged texts, continuous numbering, short cycle times and small quantities....

Open the catalog to page 3

Impact marking machineS Impact spring-spindles The simple constructed impact spring-spindles guarantee a reliable and trouble-free operation at frequent, strong use of stamping, marking, embossing, signing, riveting, mounting, punching, crimping, banding or flanging. Wherever high performance within a small area is required, the use of the compact impact spring-spindles is suitable. Only a one feed mechanism is necessary to move the spring-spindle with the appropriate power against the work piece. Both in the customized production and in the multi-shift production process, the impact...

Open the catalog to page 4

Functionality 1. Phase APPROACHING: Already at the return, the machine prepares itself automatically to the following impact. 2. Phase COMPRESSION: The work piece is fixed automatically. No clamping device is necessary. The compression process starts with the first contact to the work piece and through to this no impact will go nowhere. A continuous percussion power can be reached also when marking work pieces of different heights. 3. Phase IMPACT: The percussion pin is blocked directly after the impact and no backstroke will be created. A constant percussion power can be guaranteed. Manual...

Open the catalog to page 5

Pneumatic extension units Robust power device for production use for example on automatic turntables. Identical principle of operation as described at the pneumatic table machine. The hand lever is blocked during the impact process but is very helpful while setting up the machine. Available types of machines: MINI - MARKATOR® MV 12 U MIDI - MARKATOR® MV 21 U MAXI - MARKATOR® MV 35 U (See table below for the technical data) Pneumatic installation units In these compact marking devices, the impact spring-spindle is space-saving integrated in the piston rod of the pneumatic cylinder. It moves...

Open the catalog to page 6

Pressure marking machines If very strong forces are needed for marking, this pneumo-hydraulic embossing presses are the ideal addition to the impact spring-spindle machines. Exclusively compressed air is necessary for the use of this universal applicable, heavy table machines. The compact, pneumo-hydraulic work cylinder acts as an effective pressure multiplier with minor investment- and operating costs. High operational reliability in long time use is guaranteed through to the nearly maintenance-free conception of the installation unit. Available types of machines: MARKATOR® MV 50/10...

Open the catalog to page 7

roll marking machines Using the MARKATOR® roll marking machines, durable markings on individual work pieces can be reached with less expenditure of force. Either manual or pneumatic driven machines are moving the embossing tool pre-compressed tangential over massive or hollow round work pieces. The marking takes place radial or axial into the turning work piece. With special embossing wheels it is very simple to mark also flat work pieces. Available types of machines: Manual MARKATOR® MV 41 M, embossable diameters up to 55 mm Manual MARKATOR® MV 70 M 1, embossable diameters up to 90 mm...

Open the catalog to page 8

Hot stamp marking machines Hot stamp marking machines can control the temperature of the embossing tools and are used mainly for the blind embossing of plastics. At this marking method the pressure is replaced by heat. Optionally a color foil embossing is possible. The embossing temperature can be regulated by a precise thermostat controller. Through to a depth adjustment device a fast marking without any problems and a constant marking depth can be guaranteed. Also an oxidation at the embossing can be prevented. The feed motion of the hot stamp tools can be released either manual or...

Open the catalog to page 9

Stamp tool The MARKATOR® stamping tools are exclusively made of high-quality special stamping steel which is thoughly hardened. Because of this the tools are also suitable for the use in impact marking machines, press marking machines and roll marking machines. Highest life-times at stamping or embossing materials up to a strength of approx. 120 daN are guaranteed. All MARKATOR® type holders and numbering heads are equipped with an internal thread M 12 for self-manufactured clamping spigots. Through to this they can be used with a hand punch shaft, as a hand-held tool and also as a machine...

Open the catalog to page 10

Numbering head MARKATOR® numbering heads are mechanic precision tools of highest quality. They reach a maximum, dynamic (impact-) pressure force of up to 50 kN or a static (hydraulic/pneumatic) pressure force of up to max. 80 kN. Equipped with a brass cage and with nickel plated wheels for optimized heat conduction, the tools in the heatable version are also suitable for the hot stamping. Available types of machines: Hand-punch numbering head MV 7 Hand adjustable numbering head MV 4 Touch adjustable numbering head MV 14 Automatic numbering head MV 2 Special models of numbering heads...

Open the catalog to page 11All MARKATOR Manfred Borries GmbH catalogs and technical brochures

-

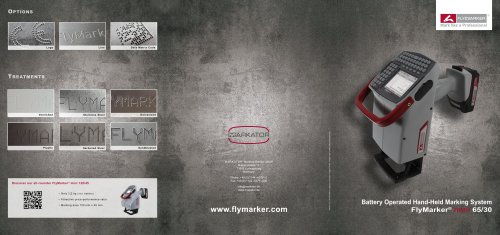

FlyMarker ® mini 65/30

2 Pages

-

FlyMarker mini

2 Pages

-

MV5 INTEGRAL

2 Pages

-

Integration Marking systems

7 Pages

-

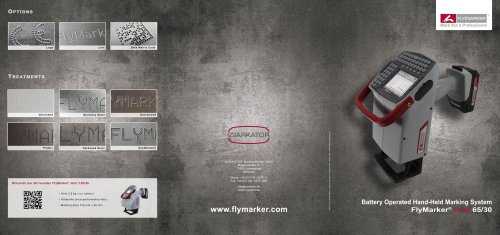

FlyMarker mini 65/30

2 Pages

-

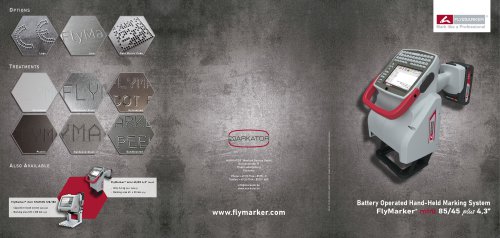

FlyMarker mini 120/45

2 Pages