Catalog excerpts

Smarelec PORTIO Intelligent Portion Cutter www.marelec.com

Open the catalog to page 1

When MARELEC launched its first PORTIO back in 2008, it answered a growing demand in the food processing market. The machine was first introduced for fish processing, but soon after, the 3-camera version was developed for the meat industry. This was the start of a successful product line that quickly developed into dedicated versions, to be used worldwide in all segments of the fish, meat and poultry processing industries. Today we are proud to present a complete range of intelligent portion cutters, from the high capacity PORTIO 1DAP for small products to the massive PORTIO 3-400 for the...

Open the catalog to page 2

Unique Selling Points The PORTIO combines state of the art technology for creating a high precision yet economic portion cutting machine. 1 // OPTIMIZED YIELD Due to our ability to scan to the highest accuracy and our highly intelligent cutting algorithm all portions are within margins and with less trim. The PORTIO software always calculates to leave zero waste on the primals, to maximize the yields. The easy fine-tuning interface allows you to make conditional programs resulting in increased yields. Combinations of fixed thickness and various fixed weights allow to portion the primals to...

Open the catalog to page 3

/ 6 / MAINTENANCE MARELEC has opted to use well reputed international brands for electrical, pneumatic and other components, which can easily be found worldwide. All motors and encoders are situated away from the wet area, which ensures a long lasting lifetime. There are limited lubrication points. This results in the lowest operational cost. / 7 / SERVICE MARELEC has built a very strong reputation for its after sales service. A team of service engineers is available 24/7 to reply to your queries. The machine can be connected to the internet, which allows our service team to diagnose the...

Open the catalog to page 4

PORTIO features 1 // PORTIO 1 VS PORTIO 3 The PORTIO 1 uses 1 camera from the top. This is perfect to scan the laser line that follows the contour of flat products passing through the laser light. Typical products are flat fillets or products where only fixed thickness is required. The highest possible throughput on the smallest footprint can be achieved with a dual-lane PORTIO. Two lanes are integrated into one machine which run completely independent from each other, each with their own control panel. Certain models also have the option of changing the cutting angle. Advantages of the...

Open the catalog to page 6

This machine is used to portion flat products vertically on fixed weight, such as fish or chicken fillets, or when only cutting to a fixed thickness is required. The PORTIO 1 is the basis for all models. The machine can be upgraded with 2 additional side cameras and all of the bolt-on options described on page 20. This allows modifications to the PORTIO according to your evolving products and applications over the life time of the machine. A PORTIO 3 adds two lateral cameras to the PORTIO 1. This allows the machine to improve the scanning and cover blind spots at the side of the product...

Open the catalog to page 7

PORTIO 3A Cutting at an angle gives a natural look on sliced portions or a bigger plate coverage. The PORTIO 1A has the ability to alter the angle of the knife versus the vertical position from 0° to 30° or 45° in just a few seconds. The PORTIO 1A uses the laser camera from the top. A typical application for the PORTIO 1A is chicken fillets that are portioned to a target weight and yet look as though they have been cut by hand from the breast caps. The adjustment of the cutting angle is done without the need for tools and comes with the patented system that automatically adjusts the gap...

Open the catalog to page 8

The PORTIO 1F combines the proven scanning and cutting technology from the PORTIO 1, with a compact design, when product lengths are less then 700 mm. Typical applications are flat chicken or fish fillets that are portioned to fixed weights or thickness at a vertical cut, when the option of a product holder is not required. For the larger pieces of meat that exceed the width of 240 mm, MARELEC has added 3 wider PORTIO models to its product range, with a possible belt width of 300mm, 350 mm or 400 mm. These PORTIOs, all equipped with 3 cameras, feature a robust execution to make...

Open the catalog to page 9

PORTIO 1DAP ® Designed to comply with the demand for high capacities in the meat processing industry, the PORTIO 3D is a dual lane machine featuring 300mm belts and lateral cameras for maximal scanning precision. As other typical meat machines, it has separate infeed conveyors to reduce the impact of placing a heavier piece of meat while still scanning the previous piece. A variety of options, typically designed for meat processing, are described on page 20. For the highest capacity on poultry and smaller fish fillets, MARELEC has developed a dual lane PORTIO with 229 mm belts, allowing to...

Open the catalog to page 10

The Retractable Outfeed allows to separate the head and/or tail trim from the product. At the end of the outfeed, the belt will retract under the product to drop the trim into a crate underneath. The rest of the portions will be separated by a conveyor behind the RO. / 1 / DENSITY SCALE OR DYNAMIC INFEED WEIGHER When the density of the products varies, the expected accuracy can be obtained using a Density Scale or Dynamic Infeed Weigher (DIW) before the PORTIO. The weight of each individual product is communicated to the PORTIO which will calculate the correct density automatically, for...

Open the catalog to page 11

Demo / SEEING IS BELIEVING / MARELEC Food Technologies has a state of the art demonstration room where customers are welcome to test the PORTIO with their own products. We strongly believe this is the best way to convince our dear customers of the quality of the cut, the accuracy, capacity and the obtained yields, gains and fast return on investment, using the MARELEC PORTIO. Please contact the MARELEC sales team to make an appointment. We will make sure to have the correct machine for your application available for a successful demonstration.

Open the catalog to page 12

IN BALANCE WITH YOUR NEEDS MARELEC Food Technologies Redanweg 15 - 8620 Nieuwpoort - Belgium - T +32 58 222 111 - sales@marelec.com

Open the catalog to page 13All MARELEC Food Technologies BVBA catalogs and technical brochures

-

MARELEC PR2 Printer

1 Pages

-

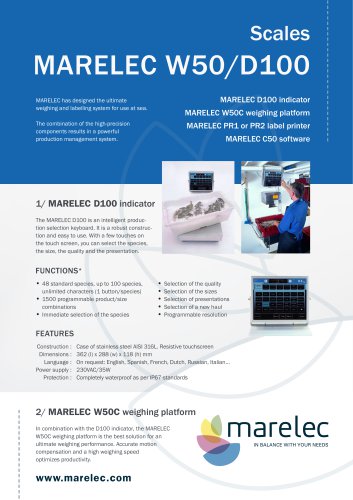

Scales MARELEC W50/D100

2 Pages

-

MARELEC PR1 Printer

1 Pages

-

GRADING SOLUTIONS

11 Pages