Catalog excerpts

Serving the Food, Beverage & Dairy Industries Worldwide since 1963 I'l'iW.'.'i't'il.VinViNVt’i'i’i'i'i'iVi/i'i ^VkViViVkViViVjv.vjViV.'.nv.',

Open the catalog to page 1

Table of Contents Sonic Air Drying Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Sonic Blower-Powered Air Knife Drying Introduction . . . . . . . . . . . . . . . . . . . . . . 2 Sonic Air Knife Operating Cost Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Bottle & Can Drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5 SMART Air Knife Water & Noise Containment Tunnel . . . . . . . . . . . . . . . . . . . . . . 6 Product Cooling/Drying Prior to Packaging . . . . . . . . . . . . . ....

Open the catalog to page 2

SNAPSHOT OF SONIC DRYING SYSTEMS AIR KNIFE BOTTLE, CAN & CONTAINER DRYING SMART AIR KNIFE TUNNELS HEPA FILTER FOR COOL AIR HEPA FILTER FOR UNPACKAGED SANITARY DRYING SANITARY TANK DRYING STANDARD PATENTED AIR KNIFE CHOICES STAINLESS STEEL & CUSTOM ENCLOSURES Fond du Lac, Wisconsin 920-921-4760 Serving food processors since 1963 Countries outside the U.S., U.S. funds only! Prices and conditions are subject to change without notice. Marchant Schmidt, Inc. is not responsible for typographical errors.

Open the catalog to page 3

Drying Systems Marchant Schmidt established a partnership with Sonic Air Systems shortly after Sonic’s inception. Since 2001, MSI has worked closely with Sonic in providing solutions for a wide range of moisture removal, debris removal, product cooling and FDA-HEPA filtered air applications. Sonic is the recognized leader in engineered “blower-powered” air knife solutions. Sonic’s vast experience with thousands of customers worldwide provides the assurance that there will be no moisture or debris related problems outside or inside a product container impacting lid, pop top and crown drying,...

Open the catalog to page 4

Sonic Air Knife Annual Operating Cost Comparison Single Shift Three Shifts Blow-Off Nozzles to Cover Two 6" Wide Areas Eight (8) nozzles @ 75 PSIG and 24 CFM each consumed a total of 192 CFM 42.2 HP required Flat Jets or Air Comb Nozzles to Cover Two 6" Wide Areas Six (6) flat jets @ 75 PSIG and 20 CFM each consumed a total of 120 CFM 26 HP required Air Knives to Cover Two 6" Wide Areas Two (2) six inch wide air knives @75 PSIG and 24 CFM each consumed a total of 48 CFM 10.7 HP required (see note below) To Cover Two 6" Wide Areas High Velocity, Low-Pressure Sonic XE Air Knife System Two (2)...

Open the catalog to page 5

Bottle & Can Drying The most common application of Sonic blower-powered air knife systems is bottle and can drying in the food, dairy and beverage industries. Challenges come in the form of container cleanliness, moisture removal/disposal and noise containment. Container cleanliness is very important. To ensure that every bottle and can is free of debris that may have gotten into the container from the beginning of the line, specially designed comb type air knives with an optional Sonic Ionizer Bar are tailor made to handle this task. This is accomplished by directing ionized “dust and...

Open the catalog to page 6

Bottle & Can Drying - Continued For both moisture and noise containment, Sonic Air Knife Tunnels are specifically designed with interchangeable panels to fit your container shape at tunnel entrance and exit along with catch pans and drain lines to dispose of the blown off liquid. For those very hard to get spots around twist-on lids and “easy open” pop tops, a Flex Nozzle can be added to either end of any air knife to direct high velocity air to any specific spot on the container. Stainless steel or polypropylene enclosures protect the heart of the Sonic Air Knife System by protecting the...

Open the catalog to page 7

SMART Air Knife Tunnel - Water & Noise Containment Covers removed to show Air Knife orientation in tunnel interior Sonic’s SMART Air Knife Tunnels for moisture and noise containment are available in 24" long modular sections. Using the modular sections, a tunnel system can be expanded to any length needed. Interchangeable panels matching container shape and size are available for entrance and exit openings. These easy-to-remove panels ensure that moisture and noise are contained when container shape on the line changes. With covers and container shape entrance/exit panels in place, air...

Open the catalog to page 8

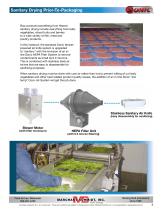

Product Cooling/Drying Prior to Packaging Fresh Cut produce along with the bakery and confectionary industries have their own set of challenges when it comes to drying or cooling the product prior to freezing or packaging. All varieties of leafy vegetables that have been pre-washed need to be dried before being sealed in their store-ready packaging. To avoid heat damage to the product, such as wilting and discoloration, that drying operation should be done with controlled, below ambient, “low temp” air. Likewise, in the bakery and confectionary industries, bakery products, snack bars, candy...

Open the catalog to page 9

Cool-Air for Product Cooling/Drying Sonic has developed a revolutionary way to cool-dry (or just cool) conveyer product prior to packaging. This feature is particularly important in the fresh-cut produce, bakery and confectionery industries where “heat is the enemy” and processing must be done with cool-air rather than heated air. Sonic Air Knife Systems has been the leader in “high temp” drying of customer products on conveyors after they are washed, rinsed or cooled with water. However, there are a variety of applications where product cannot be dried at high temperature because of...

Open the catalog to page 10

Sanitary Drying Prior-To-Packaging Raw products benefitting from filtered sanitary drying include everything from leafy vegetables, sliced fruits and berries to a wide variety of fish, meat and poultry products. In this instance, the standard Sonic blowerpowered air knife system is upgraded to “sanitary” with the inclusion of an inline Sonic HEPA Filter System to remove contaminants as small as 0.3 microns. This is combined with stainless steel air knives that are easy to disassemble for sanitizing purposes. When sanitary drying must be done with cool air rather than hot to prevent wilting...

Open the catalog to page 11