Catalog excerpts

MARA THON

Open the catalog to page 1

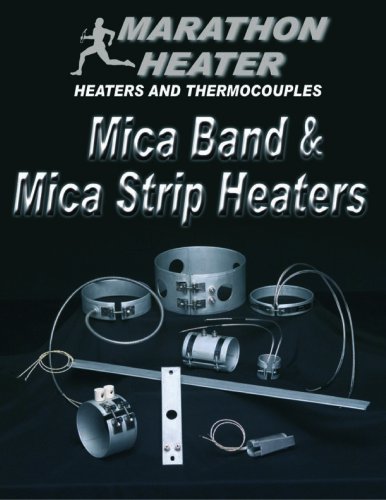

Marathon Band Heaters are computer designed and manufactured to your specifications. Only the highest quality materials are used for optimal performance. Tell us about your application so we can best serve your Band Heaters needs. Marathon Heater BAnds are Ul recognized to standard UL499 and to Canadian standard C222. File number 72-M1984 Clamping band is low thermal expansion stainless steel construction designed to maintain clamping pressure at elevated temperatures. Standard 10” fiberglass leadwires are UL rated and provide protection up to 850 degrees F. Highest grade mica insulation...

Open the catalog to page 2

FIBERGLASS LEAD TERMINATIONS ORDER TYPE L1 • Leads may exit at right • Leads exiting both • • sides of gap are standard unless otherwise specified. High temperature fiberglass leads are rated to 850 degrees F. Standard lead length is 10” • Lead wires exiting • • Lead wires on one side 180 degrees from gap are common on nozzle heater applications. 1.5” of sleeve protection is standard on lead exits. of gap are available on any construction. Common exit for small band heaters. Standard gap is .300” • Leads exiting straight • angle out of cap from any position on the heater. 1.5” of sleeve...

Open the catalog to page 3

STAINLESS STEEL BRAID TERMINATIONS ORDER TYPE B1 • Stainless Steel braid • • • Stainless Steel braid exiting both sides of gap. Leads are 2” longer than S/S braid. Stainless Steel braid offers both flexibility and abrasion protection. with right angle exit through cap. • Stainless Steel braid • Stainless Steel braid exiting 180 degrees from gap. • Stainless Steel braid • Stainless Steel braid • out same side of gap. Standard gap is .300” with spring guard. straight out side Leads exit sheath through brass eyelet.

Open the catalog to page 4

STAINLESS STEEL CONDUIT TERMINATIONS ORDER TYPE C3 • Flexible Stainless • • • Flexible Stainless Steel Conduit offers utmost lead abrasion protection. Leads are 2” longer than conduit. S/S Conduit is sometimes referred to as armor cable or hose. Steel Conduit exiting through right angle cap. POST TERMINATIONS ORDER TYPE N1 • Post Terminal • • • Post Terminals Parallel Vertical position. This is standard position for heaters 2” wide and greater. #10-32 screw thread • Post Terminals each • be ordered in same position as N-1, N-2 or N-3. side of gap. This is standard position for nozzle...

Open the catalog to page 5

CLAMPING VARIATIONS WELDED ON BARREL NUT • Welded on barrel Nuts are optional on any screw or lead termination. • Excellent clamping option for heaters with holes or cutouts. • No strap to loosen or adjust. • Standard Barrel nuts are 3/8” diameter and use a 10-24 socket head cap screw. • 5/8” clearance required. WEDGE • Wedge mount is ideal for low profile clearance • • • • and when access is limited. 1/8” clearance required. Min I.D. 1” Min width 1” Standard wedge exit is out each side of gap. FLANGE • Flange lock up is best for heaters with multiple • • • holes or cut outs. 1/2” clearance...

Open the catalog to page 6

MARATHON BAND HEATER SPECIAL CONSTRUCTIONS EURO PLUG • European type construction is available for easy installation and removal. Please specify total wattage when ordering Min. I.D. 3” • Expandable Mica excellent for preventing electrical shock or electrical shorts. Terminals boxes are available on any clamping or construction style. 1.5” wide x 2.5” long x 1.87” deep Heaters allow you to open the heaters to the diameters of the barrel for easy installation. Min. I.D. 3” Heaters should only be opened all the way one time. • Box or rectangular heaters are efficient for heating • Band...

Open the catalog to page 7

SPECIAL CONSTRUCTION OPTIONS • Internal Type J or Type K thermocouples are available • Three phase construction for high wattage heaters. • Dual voltage wiring allowing the heater to run on either • • for close temperature monitoring. • Box and irregular shaped heaters can be designed to voltage at the same wattage is available on any clamping or termination design. Ground lead or terminal is available on any design. Ceramic terminal covers. your specifications. Please supply drawing on all special orders. Bayonet adapter for thermocouples. BAND HEATER ORDERING TIPS When ordering please...

Open the catalog to page 8

M ARATHON S TRIP H EATERS Marathon Strip Heaters are manufactured to your custom specifications. Marathon strip heaters feature a high temperature oxidation metal sheath and high grade mica insulation resistant to moisture and high temperatures. Nickel/Chromium resistance wire evenly wound provides for uniform and reliable heat distribution. Marathon Mica Strip Heaters are LLL recognized to standard UL499 and test to Canadian standard C222. File number 72-M1984 MICA STRIP SPECIFICATIONS Length Minimum 2.5” Maximum - Consult Sales Width Minimum 3/4” Thickness Standard .156” Fold over 1/4”...

Open the catalog to page 9

FIBERGLASS LEADS STAINLESS STEEL BRAID ORDER TYPE SB1 • Stainless Steel Braid offers a combination of flexibility and abrasion protection • Leads out same end center • Specify Braid length • Leads are 2” longer than braid • Fiberglass leads out same end center • 10” leads standard • Leads rated to 850° F ORDER TYPE SL2 • Leads out same end edge • 1/2” sleeving at exit ORDER TYPE SB2 • Leads out same end edge ORDER TYPE SL3 • Leads out opposite ends • 1/2” sleeving at exit ORDER TYPE SB3 • Leads out opposite ends • Leads out at top of heater • Brass eyelet where leads exit sheath • 1/2”...

Open the catalog to page 10

STRIP HEATER DIMENSIONS • Marathon manufactures strip heaters in a variety of • sizes and configurations. The 1.5” wide strip heater is preferred for clamping applications. • Post terminal dimensions and locations. • Butt case for applications where strip heater will be placed in a mill slot between two steel plates. • Post terminals are located 1/4” from edge of heated section. • A third terminal may be added for dual voltage, three phase operation or for easy grounding. • Mounting holes may be located anywhere on the heater • • Ceramic terminal covers 3/4” in height and 3/4” diameter 11...

Open the catalog to page 11All Marathon Heater catalogs and technical brochures

-

Tubular Heater

12 Pages

-

hotflex®

2 Pages

-

thermocouples and RTD sensors

16 Pages

-

ceramic strip heater

4 Pages

-

starflex band heater

4 Pages

-

silicone rubber heater

8 Pages

-

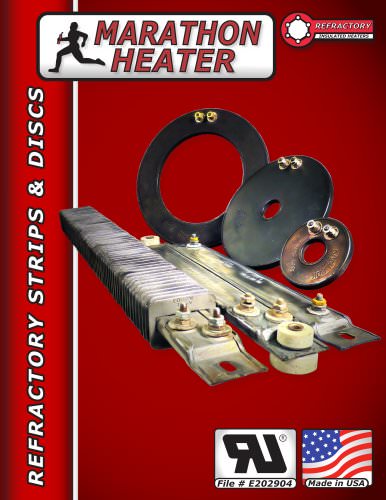

refractory strip and disc

8 Pages

-

cartridge heater

20 Pages

-

Air Process Heater

4 Pages