Catalog excerpts

© MAPLAN 09/2012 | We reserve the right to technical modifications. PC5000touch control system Standard equipment HARDWARE ● Powerful modular designed hardware, incl. flash disc ● Deterministic multitasking PLC system ● Solid State Relays for all heating zones ● „Full Size“ switch panel for all manual movements ● USB stick for data archive and user code Communication CONTROL SURFACE ● Clear presentation – ergonomic working ● Cycle configuration in graphic display ● Hot Key bar for all important machine functions (pages) provides direct page access ● Parameter input in physical values ● Switch to 3 different languages ● Access authority through key switch, Code or USB-stick ● MAPLAN DIAGNOSTIC ● Maintenance program ● Alarm system, Alarm archive ● Integration of user manual, electric plan and mechanic drawings (Hydraulic drawings) in the control surface ● Scalability – Integration of complex automations are possible ● Up to 4 individual customer pages for parameter input and actual parameter Display STATISTICS OF PRODUCTION ● PDC functions CYCLE CONFIGURATION ● CMI/OMI – cycle adjustable ● Free, graphic cycle configuration ● Support of up to 4 parallel cycles ● Automatic motion to start position CLAMPING- / INJECTION UNIT ● 10-step injection speed ● 8-step holding pressure ● Switch to holding pressure via position or hydraulic pressure ● Plasticising ramp for exact shot volume ● Electronic back pressure adjustment* ● Full-controlled back pressure* ● 3 closing speeds ● 3 opening speeds ● Mould protection TEMPERATURES ● Temperature zones with self-optimising PID controller ● Heating circuit on timer clock ● On/Off delay for the cooling units ● Emergency cooling program EJECTORS (if available) ● Ejector stroke measurement incl. speed ramp for injection- and clamp side ejectors ● Mould protection rubber injection technology DATA HANDLING ● Data archive on USB stick, Flash disc or network ● Changes of machine parameter are recorded and archived (set values and PDC) ● Alarm protocol other options on request MAPLAN GmbH Schoellergasse 9 2630 Ternitz, Austria T: + 43 2630 35706 F: + 43 2630 35408 office@maplan.at www.maplan.at * on systems with electric back pressure adjustment MAPLAN PC5000touch STATE OF THE ART CONTROL TECHNOLOGY FOR INJECTION MOULDING MACHINES, EASY OPERATION, SUPERIOR DIAGNOSTIC FUNCIONALITY, HIGH PRECISION, BEST REPEATABILITY

Open the catalog to page 1

Machine pictured may include equipment sold as options. PC5000touch Control technology One control generation for all MAPLAN injection moulding machine series and conversion kits. Highest precision and easy operation for efficient injection moulding. PC50touch for C-frame machine series and PC5000touch for T-bar machines with clamping forces up to 10.000 kN. X5touch The refurbishing solution for indestructible machines made by MAPLAN. State of the art safety technology. Thoroughgoing reliability and safety for machine and operator. MAPLAN diagnostic easy diagnostic by estimation of prompt...

Open the catalog to page 2All Maplan Maschinen und technische Anlagen catalogs and technical brochures

-

MAPLAN News_03_102014

4 Pages

-

MAPLAN News_02_042014

4 Pages

-

MAPLAN News_01_092013

4 Pages

-

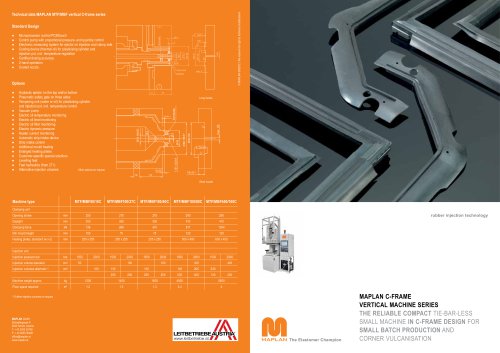

edition editionS vertical

2 Pages

-

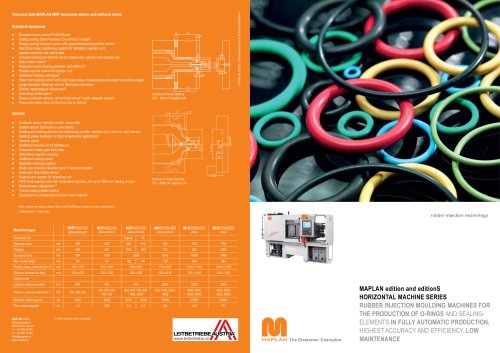

edition editionS horizontal

2 Pages

-

C-Rahmen Folder

2 Pages

-

Ergonomic

2 Pages

-

LIM

2 Pages

-

Product Overview

15 Pages

-

TPE

2 Pages

Archived catalogs

-

MAPLAN C-frame

2 Pages