Website:

Maplan Maschinen und technische Anlagen, Planungs- und Fertigungsgesellschaft m.b.H.

Website:

Maplan Maschinen und technische Anlagen, Planungs- und Fertigungsgesellschaft m.b.H.

Group: Starlinger Group

Catalog excerpts

Issue N°1/1 First is MAPL sue News AN letter The Elastomer Injection Technology Report MAPLAN the control unit specialist Control unit revolution: C6000.web Precision process in sealing engineering 30 years of innovation and experience New standards in performance and usability Kaco the sealing specialist applies a new machine concept from MAPLAN Flexible solutions for your business needs Generation 6 Control System MAPLAN again sets new standards in the field of control technology with the new control unit C6000.web. Dear readers, We are pleased to present you the first issue of “Maplan News”. As the new management team, we are excited to update you about recent MAPLAN events with this newsletter that will be issued twice a year. It is important for us to use this format to regularly inform you of our news and innovations, so you can always be on the pulse of “MAPLAN Time”. “Maplan News” will not only be a technical journal but will also be a platform to show our close working relationship with our customers and the people behind all of our successes. We chose to focus on K 2013 in the first issue. We will again present new highlights at the fair. An insight into our innovations with images and interesting texts can be found on the next 4 pages. We look forward to welcoming you personally at the K 2013 in advance and wish you a lot of fun reading the first issue of “Maplan News”. We are pleased to show you the exciting features of this control unit which will be available in 2014. Application Management MAPLAN develops and produces innovative injection moulding machines and presses, individually tailored to your corporate structure and requirements, which will optimize your business productivity. Cure² in Perfection Together with PETA, CAS and TIG, MAPLAN will show “Cure²” optimized on a a vertical 160 ton “editionS” machine with CoolDriveII®. Get an insight into the potential savings by using the latest technologies in elastomer processing. MTF750/160editionS Client Application Another new exhibit will be a vertical 580 ton, 3.5 litre “ergonomic” machine with doubleCoolDriveII® and specific equipment. This machine’s specifications will show in detail the business success of VORWERK and is the result of a close working relationship with MAPLAN to meet our customer’s requirements. System Solution The modern production of O-rings and the corresponding sealing gaskets will be shown on a horizontal 300 ton “editionS” machine with CoolDriveII® together with ORP and SYSTEM RUBBER. Wolfgang Meyer CEO Experience a state of the art automatized process chain which can be witnessed at several booths

Open the catalog to page 1

MAPLAN – the Control Unit Specialist 30 years of innovation and experience From PC106 to C6000.web, MAPLAN´s control unit technology has always been setting standards in the injection moulding of elastomers and stands for the highest performance with an ergonomic platform. At the advent of the first Programmable Logic Controllers (PLC) which began more than 30 years ago, a new era in the field of automation engineering was introduced and the control units became the focus of the plant or the machine. Based on this new control engineering, MAPLAN began with the development of a “Generation 1...

Open the catalog to page 2

Using the latest available technology, MAPLAN engineers have developed a new generation of control units that sets new standards in the field of performance and usability. New Generation Control Unit C6000.web Generation 6 Control Units Highlights • Large format: 21“ Full-HD touch-screen in portrait format sets new standards in operation and readability. • Intuitive: Innovative operating concept for simple, ergonomic function control. • Unlimited: Modern web technologies allow cross-platform display and multi-station operation. • Efficient: Modern control unit engineering guarantees...

Open the catalog to page 3

Precision Process in Sealing Engineering The sealing specialist Kaco applies a new machine concept from MAPLAN The new Kaco production line in China has been configured to manufacture transmission components. These components have a heat resistance of about 150 °C and a particular chemical resistance so that functionality is certainly ensured throughout the life cycle of the vehicle. The outer diameter of the components lies in the range of 100-300 mm. They are rubber-metal compounds which are partly formed by multiple injections from different materials. The demands on the machine posed by...

Open the catalog to page 4All Maplan Maschinen und technische Anlagen catalogs and technical brochures

-

MAPLAN News_03_102014

4 Pages

-

MAPLAN News_02_042014

4 Pages

-

PC5000 Folder

2 Pages

-

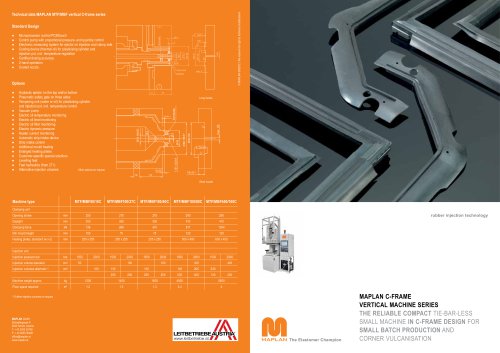

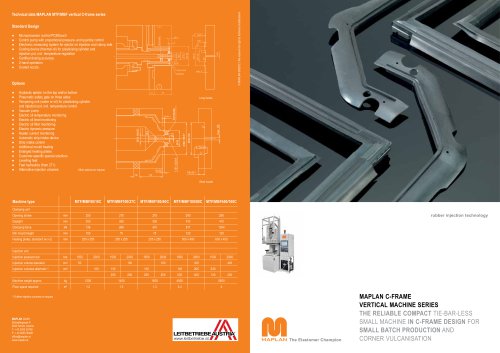

edition editionS vertical

2 Pages

-

edition editionS horizontal

2 Pages

-

C-Rahmen Folder

2 Pages

-

Ergonomic

2 Pages

-

LIM

2 Pages

-

Product Overview

15 Pages

-

TPE

2 Pages

Archived catalogs

-

MAPLAN C-frame

2 Pages