Catalog excerpts

© MAPLAN 09/2012 | We reserve the right to technical modifications Technical data MAPLAN MHF horizontal LIM edition and editionS series Standard equipment Energy saving Maplan Cool Drive – system* Microprocessor-control PC5000touch Linear positioning system for clamp and injection unit, ejector injection and clamp side 4 cooling circuits with flow control (2 of them user-specific adaptable) Oil filter-, oil level- and oil temperature monitoring* Optimized footprint MAPLAN LIM-high-precise injection unit with FIFO principle Retractable injection unit for high flexibility Cooled nozzle and injection pot Easy cleaning of plasticizing cylinder, screw and injection pot Special-LSR-non-return valve Mould and nozzle situation Central Ejector Hydraulic ejector injection and/or clamp side Heating and cooling devices for injection pot, machine nozzle caps or cold runners Vacuum pump Microprocessor control features for PC5000touch Pneumatic safety gate front side Additional heating zones Magnetic clamping system Heating plates 3-zone heating plates control with solid state relays Reinforced heating plates 390x400mm (only without ejector) Brush devices single / double - and/or knockout devices Power factor correction injection unit for LSR LIM – screw injection unit (FIFO) User-specific machine nozzles Static mixer Shut-of-nozzle Further options on request * editionS type, ** edition type Clamping unit Opening stroke Clamping force Mould mounting plates (h x d) Distance between tie bars Injection volume standard Injection unit alternative Machine weight approx. Floor space required rubber injection technology Injection unit MAPLAN GmbH Schoellergasse 9 2630 Ternitz, Austria T: + 43 2630 35706 F: + 43 2630 35408 office@maplan.at www.maplan.at Machine type injection volumes on request MAPLAN LIM edition and editionS Horizontal machine series INJECTION MOULDING MACHINES FOR PROCESSING LIQUID SILICONES, HIGHEST PRODUCT QUALITY, user friendly, LOW MAINTENANCE

Open the catalog to page 1

Machine pictured may include equipment sold as options. MHF horizontal LIM edition and editionS LIM injection moulding machines for liquid silicone applications The latest milestone in the development of a machine series with a long record of success: An all-new injection system that offers highest precision, compact design and an ease of maintenance never before achieved. Product range Production of moulded parts from LSR (Liquid Silicone Rubber) at injection volumes up to 400 cm3. Easy maintenance Cleaning of injection unit in a few easy steps – complete disassembly for cleaning takes...

Open the catalog to page 2All Maplan Maschinen und technische Anlagen catalogs and technical brochures

-

MAPLAN News_03_102014

4 Pages

-

MAPLAN News_02_042014

4 Pages

-

MAPLAN News_01_092013

4 Pages

-

PC5000 Folder

2 Pages

-

edition editionS vertical

2 Pages

-

edition editionS horizontal

2 Pages

-

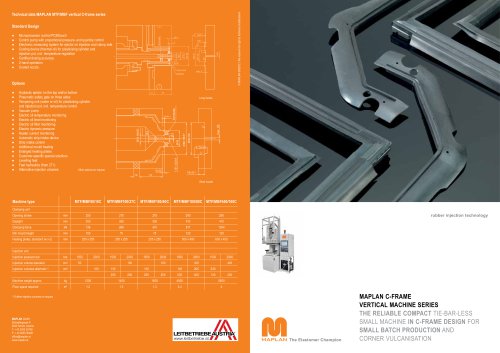

C-Rahmen Folder

2 Pages

-

Ergonomic

2 Pages

-

Product Overview

15 Pages

-

TPE

2 Pages

Archived catalogs

-

MAPLAN C-frame

2 Pages