Website:

MAPAL

Website:

MAPAL

Group: MAPAL

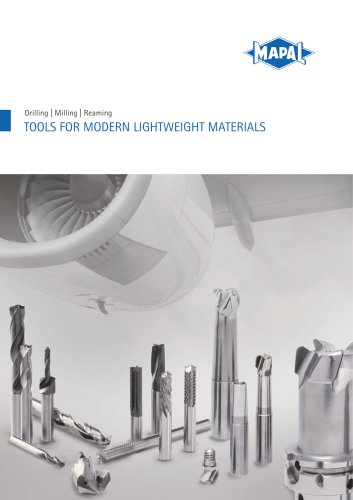

Catalog excerpts

Conventionally and additively manufactured

Open the catalog to page 1

DRILLING | QTD insert drill Sturdy insert connection, simple clamping system With the latest manufacturing technology from 8 to 32.75 mm diameter High performance, long tool lives and fast tool changing are the demands made on tool concepts today. In view of rising carbide prices, resource conservation and simple reconditioning are also playing an ever more important role today in the choice of the right tool system. In order to meet these demands even more flexibly and to offer greater customer focus, MAPAL has expanded its range of replaceable heads. The QTD insert drill has now been...

Open the catalog to page 2

DRILLING | QTD insert drill -- High availability from stock -- Same performance as solid carbide drills -- Diameter range from 8 - 32.75 mm -- High radial run-out accuracy -- Highest performance -- Sturdy collar for connection of high axial -- Error-free insert installation -- Inserts for steel, stainless steel, aluminium and cast iron -- With internal cooling -- Special surface coating -- Optimum chip formation in the -- Secure clamping of the insert with Torx Plus® screw insert and chip removal -- One holder for all bore geometries -- Robust system -- Several insert changes per -- Simple...

Open the catalog to page 3

DRILLING | QTD insert drill

Open the catalog to page 4

DRILLING | QTD insert drill Additive manufacturing First series-mature production of QTD insert drills using the additive manufacturing process The QTD insert drill for the diameter range below 13 mm (patent pending) is now produced for the first time using the additive manufacturing technology. This new technology offers new and previously untapped possibilities in production. Within the space of the laser printer, tool geometries can be created unhindered by machine clamps, tools and production means. A broad and continually expanding range of materials is available for the additive...

Open the catalog to page 5

DRILLING | QTD insert drill Description code Cylindrical design with internal cooling Smallest bore diameter Minimum drilling depth Shank diameter

Open the catalog to page 6

DRILLING | QTD insert drill Description code Number of guiding chamfers Cutting material / coating Type 1 Type 2 Type 3 Type 4 Cutting material recommendation Highly suitable Suitable in some situations Type 1 Steel Type 2 Inox Type 3 Aluminium Type 4 Iron Ordering example for intermediate sizes QTD for steel machining in 13.10 mm diameter: QTD-2F01-1310-HP240

Open the catalog to page 7

DRILLING | QTD insert drill

Open the catalog to page 8

DRILLING | QTD insert drill Insert drill with the performance of a solid carbide drill. Extensive product range for all applications. Insert holders QTS insert holder, 1,5xD - Internal coolant supply 14 QTS insert holder, 3xD - Internal coolant supply 15 QTS insert holder, 5xD - Internal coolant supply 16 QTS insert holder, 8xD - Internal coolant supply 17 QTS insert holder, 12xD - Internal coolant supply 18 Setting and handling notes Accessories and spare parts 21 Machining values

Open the catalog to page 9

DRILLING | QTD insert drill Design: Type 1 | 2 Drill diameter: 8.50 - 32.75 mm* Tool tolerance: Type 1: m7 | Type 2: h7 Coating: Type 1: Special TiAlSiXN coating Type 2: Special TiAlCN coating Number of cutting edges: 2 Number of guiding chamfers: 2 Tip angle: 135° made of solid carbide Cutting material recommendation: Type 1 Steel Type 2 For additively manufactured basic holders Type 1 For conventionally manufactured basic holders 13,00 13,50

Open the catalog to page 10

DRILLING | QTD insert drill * Intermediate sizes available from stock at short notice. Ordering information, see page 7.

Open the catalog to page 11

DRILLING | QTD insert drill Design: Type 3 | 4 Drill diameter: 8.50 - 32.75 mm* Tool tolerance: Type 3: n7 | Type 4: m7 Coating: Type 3: uncoated Type 4: Special TiAlSiXN coating Number of cutting edges: 2 Number of guiding chamfers: 2 Tip angle: 135° made of solid carbide Cutting material recommendation: Type 3 Aluminium Type 4 For additively manufactured basic holders Type 3 For conventionally manufactured basic holders 13,00 13,50

Open the catalog to page 12

DRILLING | QTD insert drill * Intermediate sizes available from stock at short notice. Ordering information, see page 7.

Open the catalog to page 13

DRILLING | QTD insert drill Design: Diameter: 8.00 - 32.99 mm Shank form: ISO 9766 Changing system: V-block mounting, insert change on the machine possible QTS100 with V-block mounting for QTD inserts, internal coolant supply Additively manufactured basic holder Dimensions Conventionally manufactured basic holder 13,00 13,50 For accessories and spare parts see page 21.

Open the catalog to page 14

DRILLING | QTD insert drill Design: Diameter: 8.00 - 32.99 mm Shank form: ISO 9766 Changing system: V-block mounting, insert change on the machine possible QTS100 with V-block mounting for QTD inserts, internal coolant supply Additively manufactured basic holder Dimensions Conventionally manufactured basic holder 13,00 13,50 For accessories and spare parts see page 21.

Open the catalog to page 15

DRILLING | QTD insert drill Design: Diameter: 8.00 - 32.99 mm Shank form: ISO 9766 Changing system: V-block mounting, insert change on the machine possible QTS100 with V-block mounting for QTD inserts, internal coolant supply Additively manufactured basic holder Dimensions Conventionally manufactured basic holder 13,00 13,50 For accessories and spare parts see page 21.

Open the catalog to page 16

DRILLING | QTD insert drill Design: Diameter: 8.00 - 32.99 mm Shank form: ISO 9766 Changing system: V-block mounting, insert change on the machine possible QTS100 with V-block mounting for QTD inserts, internal coolant supply Additively manufactured basic holder Dimensions Conventionally manufactured basic holder 13,00 13,50 For accessories and spare parts see page 21.

Open the catalog to page 17

DRILLING | QTD insert drill Design: Diameter: 13.00 - 32.99 mm Shank form: ISO 9766 Changing system: V-block mounting, insert change on the machine possible QTS100 with V-block mounting for QTD inserts, internal coolant supply Conventionally manufactured basic holder Dimensions For accessories and spare parts see page 21.

Open the catalog to page 18

DRILLING | QTD insert drill Optimum performance with the highest cost effectiveness

Open the catalog to page 19

DRILLING | QTD insert drill Handling notes for QTD insert drills Simple changing and setting of the QTD inserts 1. Loosen the special clamping screw using the TORX® PLUS wrench supplied by turning in anticlockwise direction. 2. Remove the insert from the insert seat. 3. Clean the insert seat using compressed air. NOTE -- Use only the original screws! -- The special clamping screw must be replaced during the 5th drill head change at the latest. -- The valid tightening torque is engraved on the tool. 4. lace the new insert in the insert seat. P Tighten the special clamping screw fingertight...

Open the catalog to page 20All MAPAL catalogs and technical brochures

-

MAPAL Innovations 2021

28 Pages

-

Countersinks

2 Pages

-

MAPAL TOOLTRONIC®-S

4 Pages

-

MAPAL Competence Clamping technology

464 Pages

-

UNIBASE-M

2 Pages

-

QTD insert drill

24 Pages

-

MAPAL UNISET-P

4 Pages

-

Innovations 2014

20 Pages

-

MAPAL EasyAdjust-System

12 Pages

-

MAPAL VersaCut

16 Pages

-

MAPAL TOOLTRONIC®

16 Pages

-

MAPAL Competence Actuating Tools

36 Pages

-

MAPAL Competence PCD Tools

92 Pages

-

MAPAL Competence Solid carbide tools

266 Pages

Archived catalogs

-

MAPAL Actuating Tools

36 Pages

-

MAPAL Competence ISO Tools

72 Pages

-

MAPAL Competence drilling

166 Pages

-

News broschure

32 Pages

-

MAPAL News

32 Pages