Catalog excerpts

Gruppo Riello Sistemi GERMANY Burkhardt+Weber Fertigungssysteme GmbH Burkhardt+Weber Str. 57 - 72760 Reutlingen - Germany Gruppo Riello Sistemi UK Riello Mandelli Machine Tools UK, Ltd Unit 6 - Avenue Fields Industrial Estate - Stratford on Avon, Warwickshire CV37 OHT - UK Gruppo Riello Sistemi BELGIUM Bronlaan, 5 -1700 Dilbeek - Belgium Gruppo Riello Sistemi FRANCE Atemo Machine Outils ZAC "Les Gatines" 18, Avenue du Garigliano - 91601 Savigny-sur-Orge Cedex Gruppo Riello Sistemi NORTH AMERICA Tri-Way Manufacturing Technologies Corp. 3265 Jefferson Boulevard - Windsor, Ontario N8T 2W7 - Canada Gruppo Riello Sistemi CHINA Riello Sistemi (Shanghai) Trade Co., Ltd Room 403, Qi Fu Building - 665 Song Wei N. Road - 201613 Sonjiang Shanghai Mandelli Sistemi SpA - Via Caorsana, 35 - 29100 Piacenza - Italy

Open the catalog to page 1

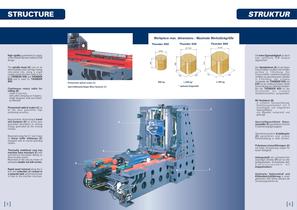

Zusammengefasst zeichnet sich die THUNDER, die kompakteste Baureihe unter den Bearbeitungszentren der Firma Mandelli, durch hohe Zuverlässigkeit und Genauigkeit kombiniert mit Leistung und Dynamik aus. In short THUNDER, the most compact of the Mandelli machining centers, means reliability, accuracy, power and speed. The self-supporting, monolithic structure, located on three points allows for it to be easily moved. Thanks to the over-dimensioned structure and to the innovative gantry design, the ratio between the fixed and mobile masses is equal to 10/1, the top of the range being the...

Open the catalog to page 2

WARUM THUNDER THUNDER produces the following components in an exceptional way: - aluminium parts thanks to high spindle speed and high axes feed; - steel and cast iron parts thanks to high power and high spindle torque. Acceleration and speed, minimum tool and pallet changing times guarantee high productivity. Die THUNDER Baureihe garantiert eine effiziente Bearbeitung von Werkstücken: - aus Aluminium aufgrund der hohen Drehzahlen und Achsendynamik; - aus Stahl und Guss aufgrund der hohen Spindelleistung und -drehmomentes. Hohe Achsbeschleunigungen und Eilgänge sowie kurze Werkzeug-und...

Open the catalog to page 3

Workpiece max. dimensions / Maximale Werkstückgröße Thunder 500 High rigidity guaranteed by means of the finished element method (FEM) design. Die hohe Eigensteifigkeit ist durch eine optimierte FEM Analyse abgesichert. The spindle head (A) runs on an electrowelded steel carriage having reticulated ribs, along a single casting portal structure made in iron for THUNDER 500 and THUNDER 630 and in steel for THUNDER 800. Der Spindelstock (A) ist auf einem Kreuzschlitten montiert und verfährt vertikal in Y-Richtung. Der Kreuzschlitten (Stahlkonstruktion) verfährt am geschlossenen Ständer in...

Open the catalog to page 4

SPINDLE HEAD THUNDER machining centers can be equipped with a wide range of spindle heads featuring: - variable preloading ceramic bearings according to rotation speed; Die Bearbeitungszentren der Baureihe THUNDER können mit verschiedenen Spindelausführungen und Zusatzeinrichtungen geliefert werden, zB.: - keramische Lager mit veränderbarer Vorspannung abhängig von der Drehgeschwindigkeit; - air-oil lubrication system; Combined boring bar - air conditioning system for control of thermal expansion. * Gearless traction motor-spindle/ Motorspindel mit direkter Übertragung **...

Open the catalog to page 5

FLEXIBLE AUTOMATISIERUNG FLEXIBLE AUTOMATION LINEAR MULTIPALLET LINEAR PALETTENSPEICHER THUNDER machining centers can be equipped with a one or two level multipallet automation system, which can be expanded by 5-pallet standard modules for THUNDER 500 and 630 and by 4 pallets for the THUNDER 800. CELL CONTROL CswWin is the cell supervisor designed and produced by Mandelli for simply and automatically handling the pallets and is capable of constantly monitoring the necessary production resources (reject component, DNC, plant status, resource forecast, tool magazine reconfiguration, control...

Open the catalog to page 6

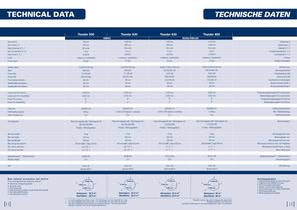

TECHNICAL DATA TECHNISCHE DATEN Thunder 630 continuous / kontinuierlich continuous / kontinuierlich continuous / kontinuierlich continuous / kontinuierlich Spindle speed Achsbeschleunigung X, Y, Z Vorschubkraft X, Y, Z B-Achse Drehgeschwindigkeit Drehzahl max. Front bearing diameter Spindle/pallet axis distance Spindle/pallet nose distance Linear axes (P) accuracy Linear axes (Ps) repeatability Rack tool magazine with / Rackmagazin mit Rack tool magazine with / Rackmagazin mit Rack tool magazine with / Rackmagazin mit Rack tool magazine with / Rackmagazin mit Pockets / Werkzeugplätzen...

Open the catalog to page 7

ENERGY ENERGIE AUTOMOTIVE KFZ-INDUSTRIE MOULDS & DIES FORMENBAU MANUFACTURING IND. ALLGEMEINER MASCHINENBAU AEROSPACE IND. LUFT- UND RAUMFAHRT

Open the catalog to page 8All MANDELLI catalogs and technical brochures

-

Transfer

12 Pages

-

Vertiflex

8 Pages

-

MACHINING CENTERS mc2 - mc4

6 Pages

Archived catalogs

-

MACHINING CENTERS Spark

7 Pages

-

Thunder Machining Center

8 Pages