Website:

Magnetrol - AMETEK

Website:

Magnetrol - AMETEK

Group: AMETEK

Catalog excerpts

Special Applications Series Heat Rate Awareness Minimizing Controllable Losses Through Effective Feedwater Heater Level Control In today’s challenging economic and regulatory environment, i ncreasing the efficiency of your power plant is a mission-critical r equirement. Taking control of your heat rate can help you use e nergy more efficiently, minimize fuel costs and boost your bottom line.

Open the catalog to page 1

The Heat Rate Imperative Today’s business climate creates numerous challenges for power companies. The Clean Air Act and new climate change protocols have put power plants under increased government regulation. The need to comply with these changing standards while also generating sufficient revenue has made heat rate a key performance indicator for all power plants. Before you can correlate any heat rate technology to a return on investment, you must first understand heat rate, its value to your business and the impact that improved heat rate can provide. Improving heat rate 1% can...

Open the catalog to page 2

Causes of Heat Rate Inefficiency and Fuel Cost Acceleration Most power plants have a life expectancy of 30 - 40 years with many at or reaching their operational longevity. In addition, these plants often use outdated level technologies that cannot achieve a performance level sufficient to manage controllable losses due to instrument-induced errors: • Mechanical or electronic drift due to aging instrumentation, moving parts or intrinsic design. Torque tube/displacer technology requires calibration between shutdowns to achieve reasonable accuracy and prevent nuisance deviation alarms between...

Open the catalog to page 3

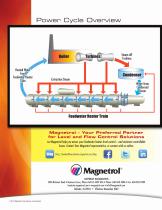

Effectively Measuring and Controlling Heat Rate at Your Facility Reducing heat rate drives overall plant performance – and fuel cost savings. The basic power cycle for a typical steam plant begins at the condenser, where condensed steam from the feedwater heater drains and LP Turbine is routed through each successive stage of feedwater heaters. At the same time, extraction steam from your turbines reaches the appropriate feedwater heaters and the transfer of energy takes place. Maintaining accurate and reliable level controls throughout this cycle is critical to achieve the final feedwater...

Open the catalog to page 4

Better Feedwater Heater Level Control Generates Greater Benefits Maintaining optimum water level is a critical component of maximizing energy transfer and minimizing controllable losses. Optimizing feedwater heater level control is an effective way to easily improve efficiency (heat rate) and reduce fuel costs. However, a basic familiarity with feedwater operation is critical to understanding how level control can impact your plant. Feedwater heaters use the heat of condensation to preheat water to the correct temperature for the boiler. During this process, shell and tube heat exchangers...

Open the catalog to page 5

Proven Portfolio of Heat Rate Control Solutions The Cornerstone of Heat Rate Reduction Magnetrol® products provide the highly accurate level control needed to satisfy the most complex applications. Our product portfolio provides a full array of innovative and reliable level measurement solutions for feedwater heaters, including: • ECLIPSE® Guided Wave Radar (GWR) Transmitter. Magnetrol’s new ECLIPSE Model 706 overshadows current levels of GWR performance. Virtually unaffected by process variations, the 706 gives you a superior degree of accurate and reliable continuous level measurement –...

Open the catalog to page 6

The Heat Rate Expertise You Need Minimize Your Heat Rate and Total Cost of Ownership with Magnetrol Finding the right partner – one that understands your process and applications – is vital to your success. That partner is Magnetrol. We combine more than 80 years of experience in level and flow control with a comprehensive range of technologies to deliver the highly effective solutions that allow you to realize a true return on investment. With Magnetrol, you get the best of both worlds. A proven portfolio of level controls – from a company with decades of experience implementing them to...

Open the catalog to page 7

Power Cycle Overview Magnetrol – Your Preferred Partner for Level and Flow Control Solutions Let Magnetrol help you assess your feedwater heater level control – and minimize controllable losses. Contact Your Magnetrol representative, or connect with us online: http://levelandflowsolutions.magnetrol.com/blog CORPORATE HEADQUARTERS 5300 Belmont Road • Downers Grove, Illinois 60515-4499 USA • Phone: 630-969-4000 • Fax: 630-969-9489 heatrate.magnetrol.com • magnetrol.com • info@magnetrol.com Bulletin: 41-189.0 • Effective: November 2012

Open the catalog to page 8All Magnetrol - AMETEK catalogs and technical brochures

-

E4 Modulevel®

12 Pages

-

Crude Oil Processing

8 Pages

-

Natural Gas Processing

12 Pages

-

Interface In The Field

14 Pages

-

Emulsion In The Field

9 Pages

-

PRODUCT LINE CATALOGUE

106 Pages

-

Aurora® Magnetic Level Indicator

28 Pages

-

Atlas™ Magnetic Level Indicator

24 Pages

-

STEAM DRUM LEVEL MATTERS

1 Pages

-

INTERFACE IN THE FIELD

1 Pages

-

Echotel® 355

4 Pages

-

Power Generation

16 Pages

-

Petroleum Refining

16 Pages

-

Seal Pots

4 Pages

-

Mass Flow Measurement

12 Pages

-

Interface Level Measurement

8 Pages

-

Ethylene Applications

8 Pages

-

Thermatel® TD1/TD2

16 Pages

-

Kotron® 082

4 Pages

-

Enhanced Jupiter®

16 Pages

-

GEMINI™

32 Pages

-

Aurora®

32 Pages

-

Atlas™

24 Pages

-

Horizon TM Model 704

8 Pages

-

Eclipse® Enhanced 705 Hygienic

12 Pages

-

Eclipse® Enhanced 705

8 Pages

-

Pneumatic Tuffy®

12 Pages

-

Models T5x & T6x

8 Pages

-

Models T20/T21

12 Pages

-

Series B73 and Series 75

12 Pages

-

Series 3

24 Pages

-

Model J52

2 Pages

-

Model B40

4 Pages

-

TUFFY® II

12 Pages

-

Floating Roof Detection

16 Pages

-

APM Pneumatic Modulevel®

12 Pages

-

Flue Gas Desulferization

8 Pages

-

Energy Management

4 Pages

-

API 2350 Overfill Prevention

8 Pages

-

PULSAR ® R96

1 Pages

-

Water & Wastewater

12 Pages

-

Displacer Switches

20 Pages

-

Displacer Transmitters

4 Pages

-

Guided Wave Radar

12 Pages

-

Magnetic Level Indicators

12 Pages

-

Magnetostrictive

16 Pages

-

Thermal Dispersion

12 Pages

-

Ultrasonic Contact

4 Pages

-

Vibrating Rod Switches

4 Pages

-

R Series High Temp Switch

12 Pages

-

Series K Pneumatic Switch

8 Pages

-

J Series Pneumatic Switch

8 Pages

-

Liquid Displacer Level Switches

16 Pages

-

Crude Oil Processing

8 Pages

-

Product Line Quick Reference

8 Pages