Catalog excerpts

Magnetek—the premier provider of innovative power control and delivery systems for the overhead material handling industry—brings you a superior DC control for crane, hoist and heavy moveable structure applications. We've combined Magnetek's highly successful DC drive technology, used to power over 25,000 elevator drives worldwide, with our extensive crane and hoist application experience, to bring you a state-of-the-art, fully programmable DC digital drive. The OmniPulse DSD improves safety and reliability in your facility while minimizing downtime and maximizing the performance of your DC shunt wound motor. A BETTER SOLUTION TO CONTROL DC SHUNT WOUND MOTORS • Most competitive DC drives offer you a one-size-fits-all solution to your application —and are difficult to use and hard to program • OmniPulse DSD was developed specifically to control DC shunt wound bridge, trolley and hoist motors —and they're easy to install • The patented OmniPulse DSD microprocessor digital logic controller delivers precise, repeatable AC in/DC out control —and its solid-state operation means less maintenance • Magnetek has more power control application experience than any company in the crane and hoist industry—trust the experts • Our experienced application engineers will implement cost-effective control solutions that suit your application, to meet and exceed your expectations SUPERIOR FEATURES, SUPERIOR RESULTS The fully programmable OmniPulse DSD offers many of the same advanced safety and troubleshooting features built into our proven IMPULSE® AC Drives, like: • UltraLift™—higher speeds with light loads • MicroSpeed "—precise speed control minimizes load swing during operation • Load Float—hold a load aloft at zero speed • Torque Proving at Start/Stop —monitors brake function • End of Travel Limits—slow down and stop inputs OmniPulse DSD Controls are available in component form or in panels that can be custom designed to meet your specifications. DSD also interfaces with IMPULSE®» Link 4.1 Basic or WDS (wired or wireless), offering remote parameter operation and diagnostic capabilities. OPTIONAL KEYPAD Keypad has programmable operating features and computer diagnostics, allowing the operator to customize crane, hoist or heavy moveable structure performance • Display menus provide rapid access to operating status, features and diagnostics • 2 line X 16 character LCD display • Fault-detection and safety circuits record last 16 faults that may occur and protect motors from dangerous operating conditions • Status is clearly displayed, providing fast diagnosis and repair of almost any problem YOUR ONE-STOP SOURCE FOR MATERIAL HANDLING CONTROL SOLUTIONS

Open the catalog to page 1

MAGNETEK ElECTROMOTIVE SYSTEMS SAFETY ADVANTAGES • Safe Operating Windows™ reduces the possibility of programming unsafe parameters • Motor and control protection circuits • Utilizes inputs from upper limit switches RELIABILITY ADVANTAGES • Undervoltage protection • Saves last 16 faults, automatic reset or external fault reset • Reduced mechanical stress • Microprocessor based built-in monitoring and diagnostics • Increased reliability over older technology • Built for harsh operating environments PERFORMANCE ADVANTAGES • Traverse Motion —programmable, analog or multi-step speed reference •...

Open the catalog to page 2All Magnetek catalogs and technical brochures

-

ReFlx® 45 Brochure

1 Pages

-

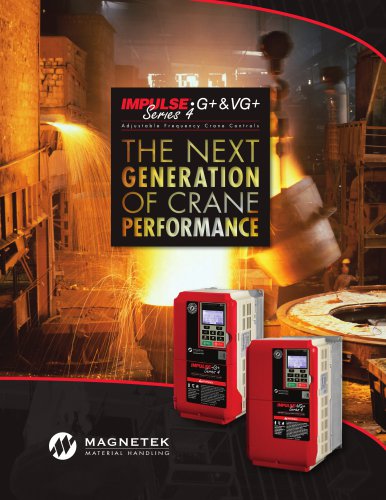

impulse_series_4

16 Pages

-

FLEX VUE Wireless Controls

2 Pages

-

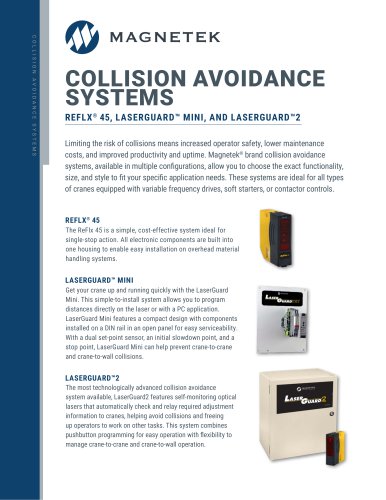

COLLISION AVOIDANCE SYSTEMS

2 Pages

-

Cable Reels Brochure

2 Pages

-

Magnetek Full Circle Service

6 Pages

-

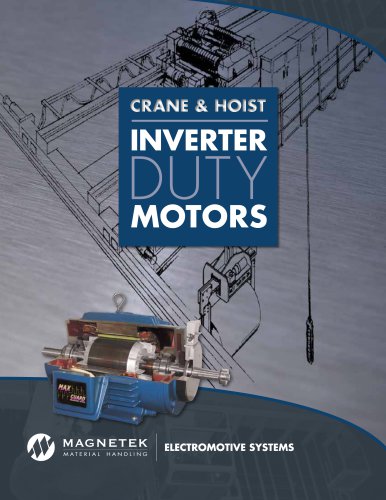

Black Max® Motors

4 Pages

-

IMPULSE®•T

2 Pages

-

DataLogger Series 4

1 Pages

-

IMPULSE®•G+ Mini

8 Pages

-

IMPULSE®•G+ Series 4

16 Pages

-

Engineered Systems & Solutions

16 Pages

-

Marine Terminal Family

8 Pages

-

Brake Accessories Brochure

2 Pages

-

Collision Avoidance Brochure

2 Pages

-

MH445_SBN

2 Pages

-

Enrange? Flex M Receiver

2 Pages

-

Enrange? CAN-6 Receiver

2 Pages

-

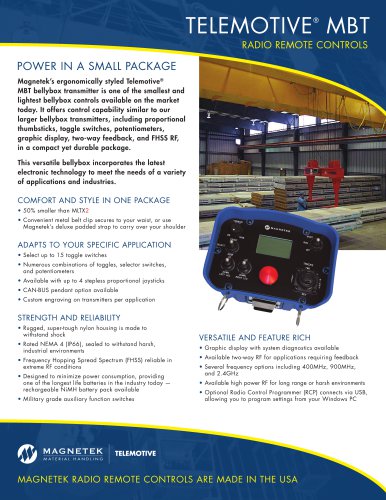

Telemotive MBT

2 Pages

-

Telemotive XLTX?

2 Pages

-

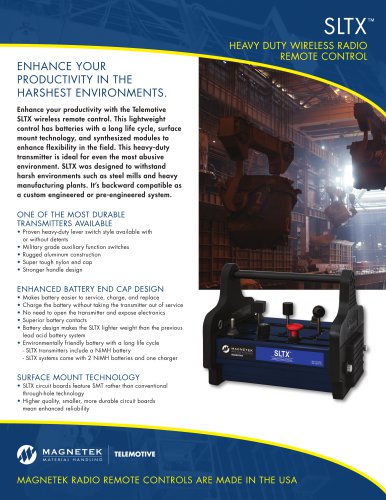

Telemotive SLTX?

2 Pages

-

Telemotive MLTX?

2 Pages

-

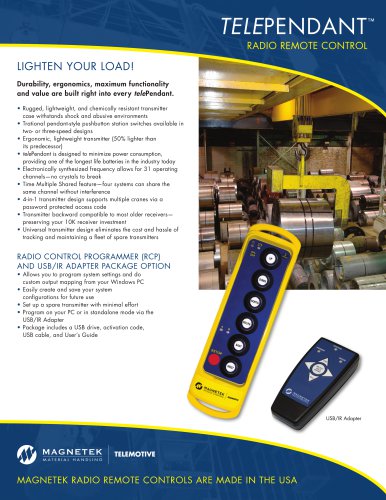

Telemotive telePendant?

2 Pages

-

Telemotive Flex VUE®

2 Pages

-

Enrange? Flex EX Series

2 Pages

-

OmniPulse? DSD DC Control

2 Pages

-

IMPULSE®?R

2 Pages

-

MAC??2000 Soft Starts

2 Pages

-

IMPULSE®?G+ Mini

6 Pages

-

IMPULSE®?G+ Series 4

16 Pages

-

Telemotive MLTX2?

2 Pages

-

Blue Max® Motors

6 Pages

-

IMPULSE®?T

2 Pages

-

ReFlx® 120

2 Pages

-

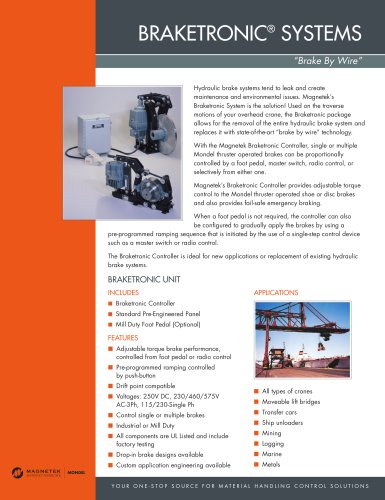

Braketronic®

2 Pages

-

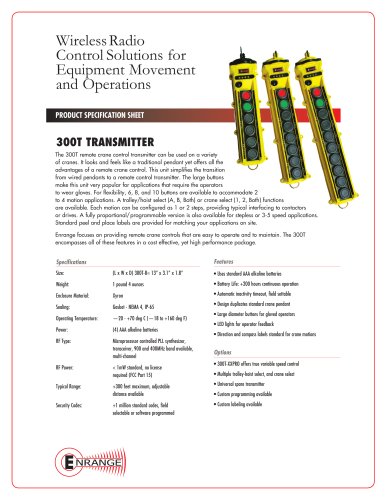

Enrange 300T

2 Pages

-

Telemotive telePendant

2 Pages

-

Enrange Flex Pro Series

2 Pages

-

Enrange Flex EX Series

2 Pages

-

Plug & Play Festoon System

1 Pages

-

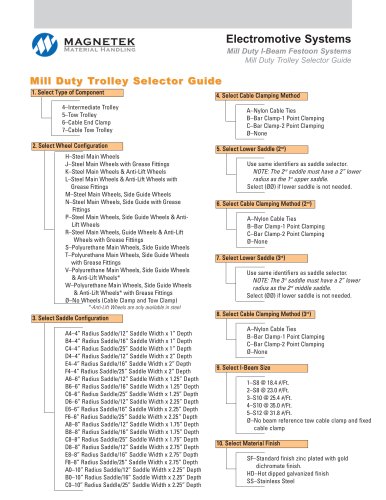

Mill Duty I-Beam Festoon

6 Pages

-

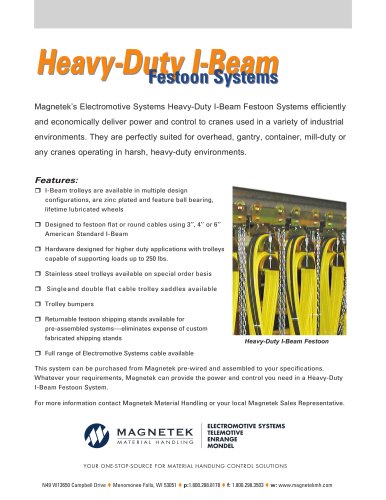

Heavy Duty I-Beam Festoon

4 Pages

-

C-Track Festoon Systems

4 Pages

-

FABA Conductor Rail System

2 Pages

-

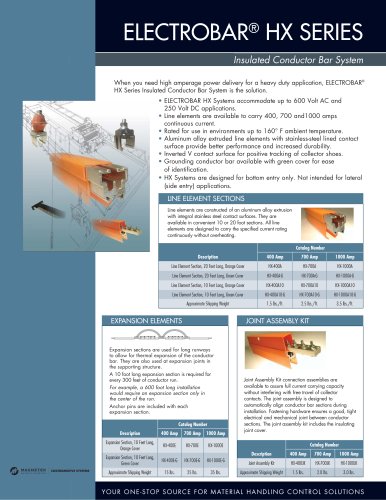

Electrobar HX Full Brochure

2 Pages

-

MAC.2000

2 Pages

-

Complete Control Panels

2 Pages

-

DataLogger Series 3+

1 Pages

-

IMPULSE®?G+ Mini Brochure

6 Pages