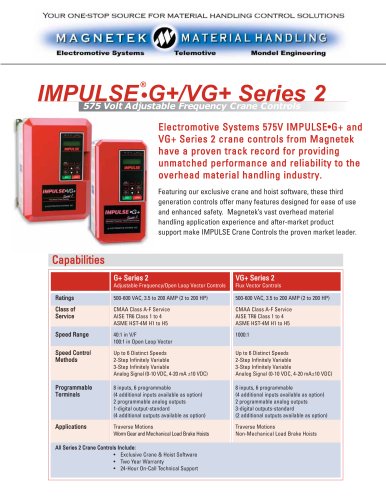

Catalog excerpts

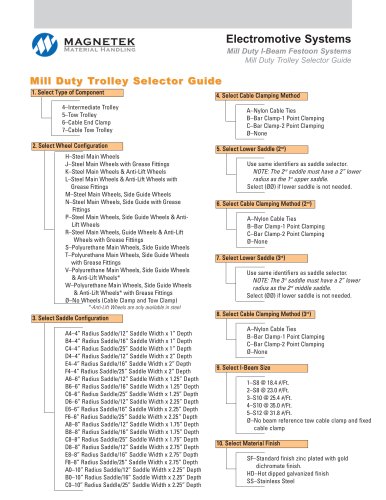

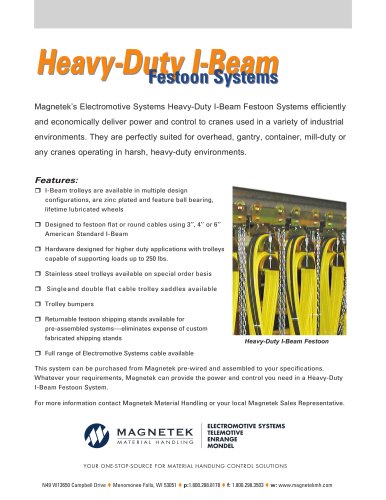

Festoon Systems Magnetek's Electromotive Systems Mill Duty l-Beam Festoon Systems efficiently and economically deliver power and control to cranes used in a variety of severe industrial □ Standard 4" diameter trolley wheel □ Capacity of flanged main wheel trolley: □ Trolleys manufactured from low carbon steel and are zinc plated with gold dichromate finish □ Bar clamps are available to secure cable □ Capacity of non-flanged trolley wheel (with side guide □ Trolleys are available with galvanized finish □ Trolleys are available in stainless steel Trolleys are available for installation on 8" through 12" l-Beams. Whatever your requirements, Magnetek can provide the power and control you need in a Mill Duty l-Beam Festoon System. Fixed Hanger Track Length System Length Total Length of festoon track or l-Beam Storage Length Loop Dept Intermediate Trolley Fixed Hanger/End Cable Clamp Total extended length of festoon system. Centerline of end cable clamp to centerline of tow Distance from centerline of tow trolley to centerline of end cable clamp when festooned equipment is parked in the starting position. Storage distance may become exceedingly long on longer festoon systems but can be shortened by increasing the loop depth of the cable. Actual tow trolley travel distance of festooned equipment from the starting position to the final position along the track length. The distance from the running surface of the track or l-Beam to the lower most point of the cable loop. The distance from the trolley saddle surface to the lower most point of the cable loop. Outer trolley that provides an area to interface with the tow bar that is mounted on the traveling portion of the festooned equipment. Trolleys are located between the tow trolley and the end cable clamp providing cable support Securescable at the beginning of the festoon system, reducing cable stress at the termination points. Cable or chain secured between each trolley to reduce cable stress along the festoon system. Primarily used in applications with heavy cable loads or high travel speeds. MATERIAL HANDLING Electromotive Systems Mondei Engineering YOUR ONE-STOP SOURCE FOR MATERIAL HANDLING CONTROL SOLUTIONS N49W13650 Campbell Drive Menomonee Falls, Wl 53051 p:1-800-288-8178 ♦ f: 1-800-298-3503 w: www.magnetekmh.com

Open the catalog to page 1

Mill Duty Tow Trolley The tow bar passes through the slot of the front end of the tow trolley to propel the trolley. The slot is oversized to provide ample room for the tow bar that eliminates any binding that may occur while system is in motion. It is recommended that anti-lift rollers be used on tow trolleys to prevent trolley from lifting while in motion. _ Cable bar clamps are optional N49W13650 Campbell Drive Menomonee Falls, Wl 53051 p:1-800-298-8178 ♦ f: 1-800-298-3503 w: www.magnetekmh.com

Open the catalog to page 4

Mill Duty Intermediate Trolley Trolleys are located between the tow trolley and end cable clamp providing cable support as the system expands. Large polyurethane bumpers on the end of each trolley are standard to damper impact between trolleys and end stops. Cable bar clamps are optional saddle width Lower Saddle Assemblies When configuring a component with lower saddles (2nd and 3rd saddles) the lower saddles must be at least 2" R less than the saddle immediately above it. Configuration Guidelines Main Saddle 2nd Saddle 3rd Saddle N49W13650 Campbell Drive Menomonee Falls, Wl 53051...

Open the catalog to page 5

Electromotive Cable Magnetek furnishes a variety of Electromotive Systems cable specifically designed for festoon applications. The cable is available in a round or flat design and most sizes are available for same day shipment. It comes standard in a safety yellow color and can be ordered with your company's name, logo and phone number imprinted on the cable when purchased in reel quantities. Standard Cable Specifications*: •Indoor/Outdoor Festoon flat cable and round pendant control cable •Conductors are annealed copper •Each conductor has color coded jacket •Resistant to UV, ozone,...

Open the catalog to page 6All Magnetek catalogs and technical brochures

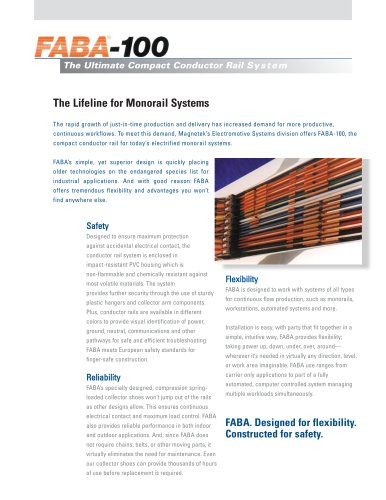

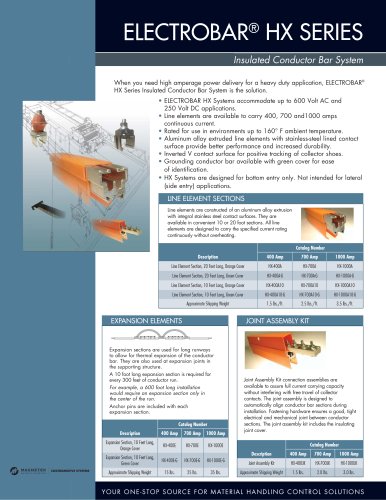

-

ReFlx® 45 Brochure

1 Pages

-

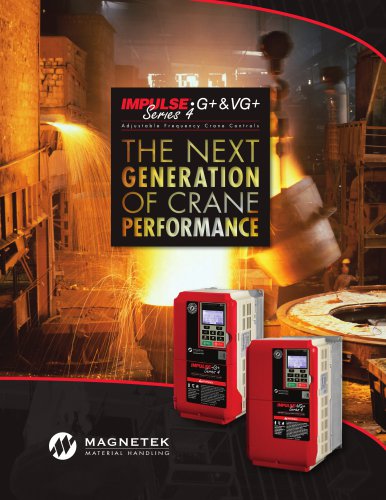

impulse_series_4

16 Pages

-

FLEX VUE Wireless Controls

2 Pages

-

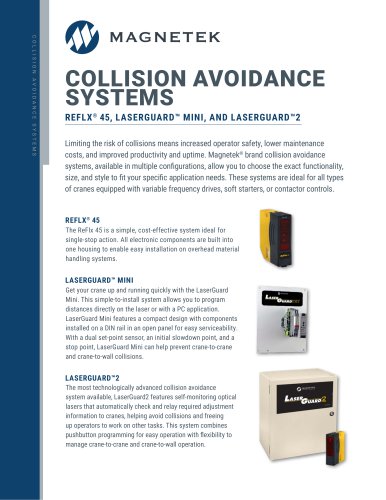

COLLISION AVOIDANCE SYSTEMS

2 Pages

-

Cable Reels Brochure

2 Pages

-

Magnetek Full Circle Service

6 Pages

-

Black Max® Motors

4 Pages

-

IMPULSE®•T

2 Pages

-

DataLogger Series 4

1 Pages

-

IMPULSE®•G+ Mini

8 Pages

-

IMPULSE®•G+ Series 4

16 Pages

-

Engineered Systems & Solutions

16 Pages

-

Marine Terminal Family

8 Pages

-

Brake Accessories Brochure

2 Pages

-

Collision Avoidance Brochure

2 Pages

-

MH445_SBN

2 Pages

-

Enrange? Flex M Receiver

2 Pages

-

Enrange? CAN-6 Receiver

2 Pages

-

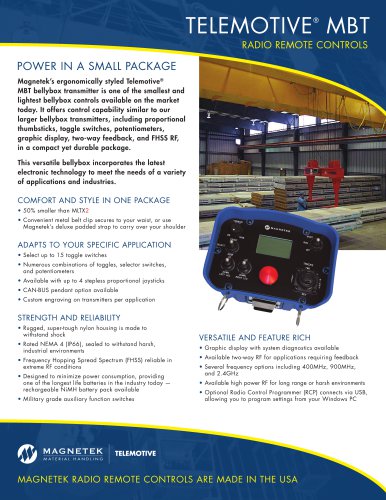

Telemotive MBT

2 Pages

-

Telemotive XLTX?

2 Pages

-

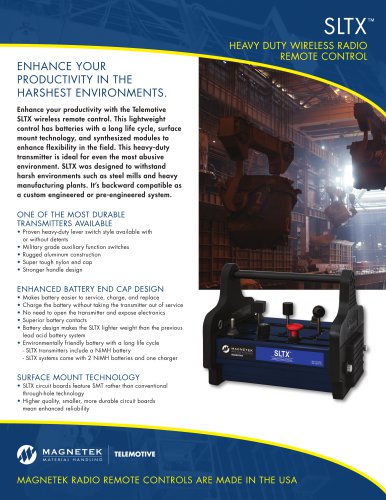

Telemotive SLTX?

2 Pages

-

Telemotive MLTX?

2 Pages

-

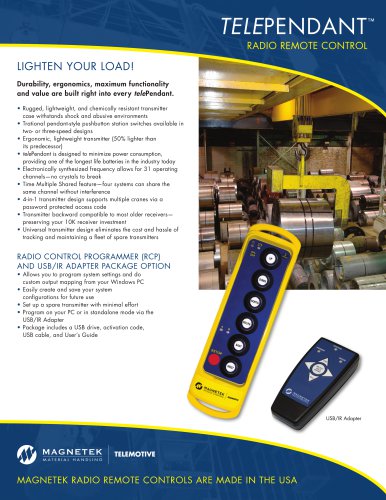

Telemotive telePendant?

2 Pages

-

Telemotive Flex VUE®

2 Pages

-

Enrange? Flex EX Series

2 Pages

-

OmniPulse? DSD DC Control

2 Pages

-

IMPULSE®?R

2 Pages

-

MAC??2000 Soft Starts

2 Pages

-

IMPULSE®?G+ Mini

6 Pages

-

IMPULSE®?G+ Series 4

16 Pages

-

Telemotive MLTX2?

2 Pages

-

Blue Max® Motors

6 Pages

-

IMPULSE®?T

2 Pages

-

ReFlx® 120

2 Pages

-

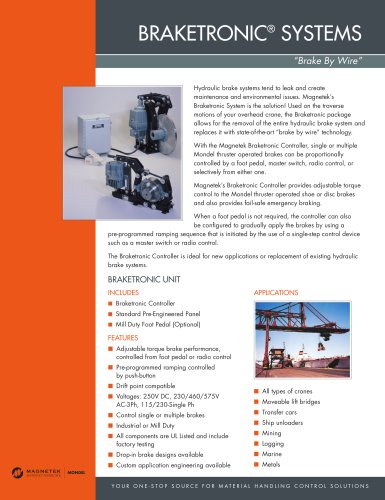

Braketronic®

2 Pages

-

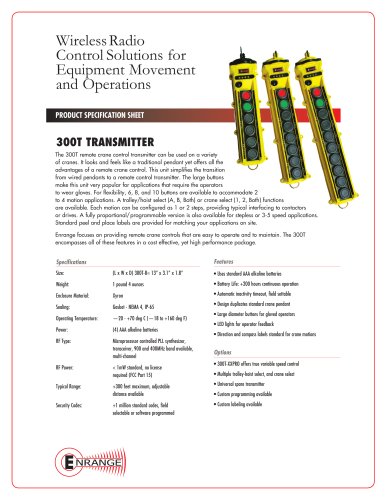

Enrange 300T

2 Pages

-

Telemotive telePendant

2 Pages

-

Enrange Flex Pro Series

2 Pages

-

Enrange Flex EX Series

2 Pages

-

Plug & Play Festoon System

1 Pages

-

Heavy Duty I-Beam Festoon

4 Pages

-

C-Track Festoon Systems

4 Pages

-

FABA Conductor Rail System

2 Pages

-

Electrobar HX Full Brochure

2 Pages

-

MAC.2000

2 Pages

-

Complete Control Panels

2 Pages

-

DataLogger Series 3+

1 Pages

-

OmniPulse DSD DC Controls

2 Pages

-

IMPULSE®?G+ Mini Brochure

6 Pages