Catalog excerpts

AC LINE REGENERATIVE SYSTEMS Magnetek’s high performance AC Line Regenerative Systems are ideal for adjustable speed applications that include a high demand braking cycle. These industrial grade units take surplus regenerative energy from the motor and return it to the AC power source, reducing total energy consumption and improving energy efficiency. IMPULSE®•D+, IMPULSE®•D+ HHP, & IMPULSE®•R+ AC REGENERATIVE SYSTEMS ARE AN IDEAL SOLUTION FOR • igh duty cycle cranes H • arge cranes with multiple resistor banks for each motion L • Severe duty, dusty, wet, or volatile environments AC REGENERATIVE SYSTEMS PROVIDE • Energy efficiency • ost savings – payback can be seen in the first year C • limination of wiring for dynamic braking resistors E • Elimination of dynamic braking resistors’ maintenance Three different unit types are available to fit your application needs. IMPULSE®•R+ units are available with ratings from 5–400 HP, IMPULSE®•D+ units are available up to 830 HP, and IMPULSE®•D+ HHP units are suitable for uses up to 2,000 HP. They can be combined with IMPULSE®•G+ or VG+ Series 3 or 4 adjustable frequency drives and sized to fit the expected regenerative need. IMPULSE•D+ IMPULSE•R+ The IMPULSE•D+ is a high-performance Active Front End Regeneration Unit in a chassis drive layout. The Active Front End technology allows the IMPULSE•D+ to minimize line harmonics below IEEE 519 requirements and regulate a consistent DC bus voltage. Combining the IMPULSE•D+ with IMPULSE•G+ and VG+ Series 4 variable frequency drives provides you with the most energy efficient, durable, and feature-rich crane control system available. The IMPULSE•D+ HHP is a modular, regenerative inverter platform designed with reliability and serviceability in mind. It utilizes Active Front End (AFE) technology to maximize crane control efficiencies with extremely low line harmonics. IMPULSE•D+ HHP units exceed the requirements defined by IEEE 519 and the common bus architecture allows the drives to share energy. Enclosures are offered with open chassis, NEMA 1, forced air cooled, or air conditioned options. IMPULSE•D+ Input Voltage +10% / -15% Input Frequency IMPULSE•D+ HHP Input Voltage +10% / -15% Input Frequency Motor Rated Current Horsepower Rating Motor Rated Current Horsepower Rating Ambient Operating Temperature Power Factor Overload Tolerance -10 to 50°C (14 to 122°F) >0.99 at full load 150% for 60 seconds, 200% for 3 seconds Ambient Operating Temperature Power Factor Overload Tolerance -10 to 40°C (104°F) >0.99 at full load 150% for 60 seconds, 200% for

Open the catalog to page 1

With our combination of extensive application experience and leading-edge products, Magnetek provides the ultimate solution for overhead motion control. IMPULSE•D + & IMPULSE•D + HHP APPLICATION DIAGRAM EXAMPLE IMPULSE•R+ The IMPULSE•R+ is designed to provide a low-cost solution to add line regeneration to your overhead crane. It is easy to operate and sized identically to the connected variable frequency drive. IMPULSE•R+ can connect to a network, via Ethernet and PLC, to monitor status in real-time, and may be installed in an explosionproof enclosure. The IMPULSE•R+ can be easily...

Open the catalog to page 2All Magnetek catalogs and technical brochures

-

ReFlx® 45 Brochure

1 Pages

-

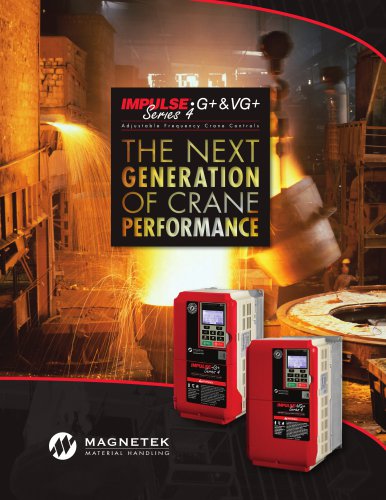

impulse_series_4

16 Pages

-

FLEX VUE Wireless Controls

2 Pages

-

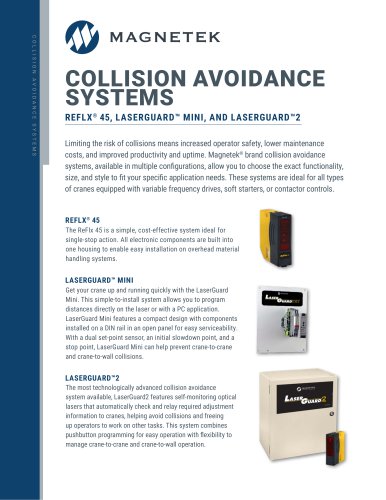

COLLISION AVOIDANCE SYSTEMS

2 Pages

-

Cable Reels Brochure

2 Pages

-

Magnetek Full Circle Service

6 Pages

-

Black Max® Motors

4 Pages

-

IMPULSE®•T

2 Pages

-

DataLogger Series 4

1 Pages

-

IMPULSE®•G+ Mini

8 Pages

-

IMPULSE®•G+ Series 4

16 Pages

-

Engineered Systems & Solutions

16 Pages

-

Marine Terminal Family

8 Pages

-

Brake Accessories Brochure

2 Pages

-

Collision Avoidance Brochure

2 Pages

-

MH445_SBN

2 Pages

-

Enrange? Flex M Receiver

2 Pages

-

Enrange? CAN-6 Receiver

2 Pages

-

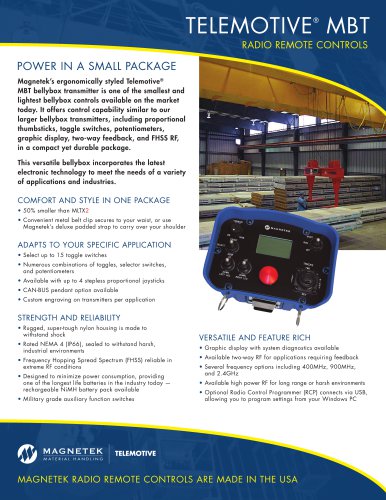

Telemotive MBT

2 Pages

-

Telemotive XLTX?

2 Pages

-

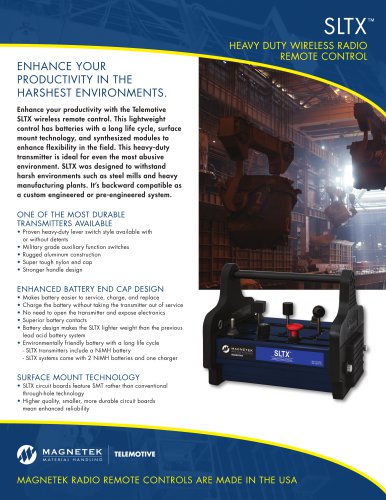

Telemotive SLTX?

2 Pages

-

Telemotive MLTX?

2 Pages

-

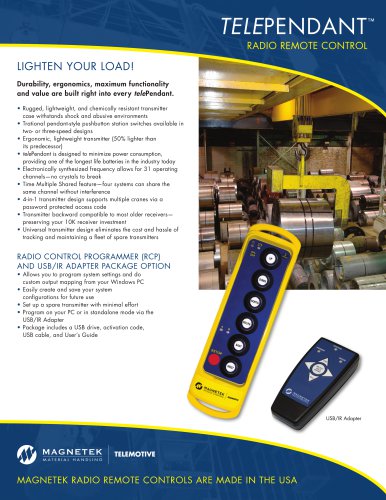

Telemotive telePendant?

2 Pages

-

Telemotive Flex VUE®

2 Pages

-

Enrange? Flex EX Series

2 Pages

-

OmniPulse? DSD DC Control

2 Pages

-

IMPULSE®?R

2 Pages

-

MAC??2000 Soft Starts

2 Pages

-

IMPULSE®?G+ Mini

6 Pages

-

IMPULSE®?G+ Series 4

16 Pages

-

Telemotive MLTX2?

2 Pages

-

Blue Max® Motors

6 Pages

-

IMPULSE®?T

2 Pages

-

ReFlx® 120

2 Pages

-

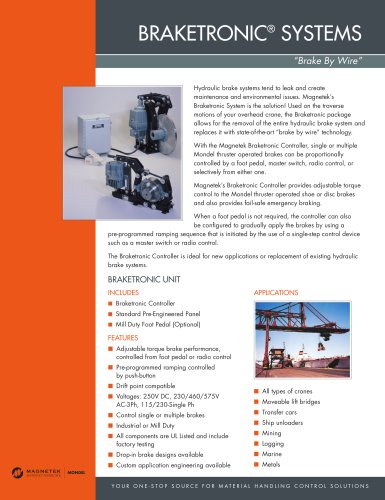

Braketronic®

2 Pages

-

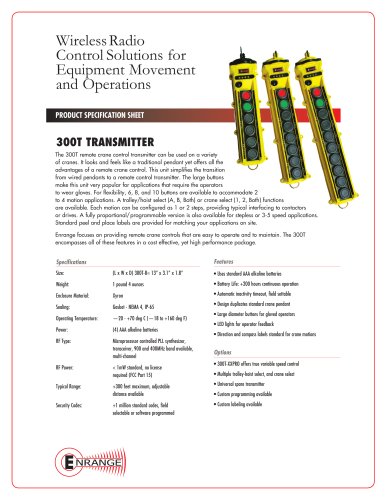

Enrange 300T

2 Pages

-

Telemotive telePendant

2 Pages

-

Enrange Flex Pro Series

2 Pages

-

Enrange Flex EX Series

2 Pages

-

Plug & Play Festoon System

1 Pages

-

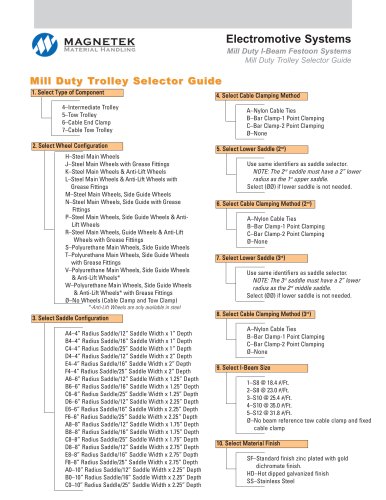

Mill Duty I-Beam Festoon

6 Pages

-

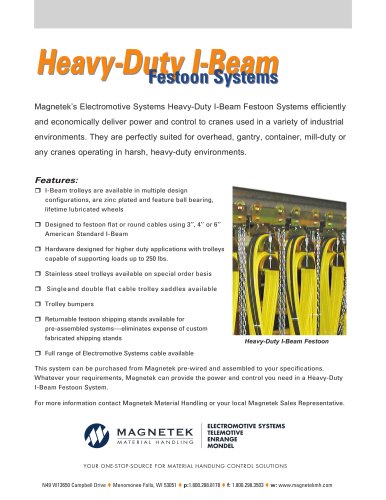

Heavy Duty I-Beam Festoon

4 Pages

-

C-Track Festoon Systems

4 Pages

-

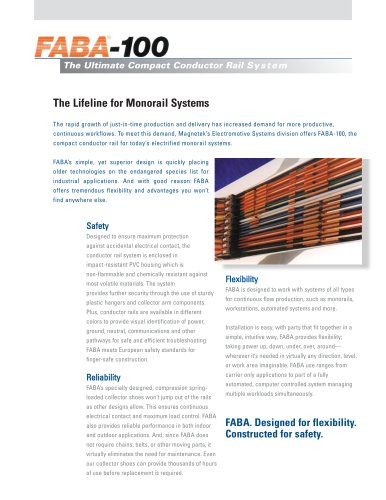

FABA Conductor Rail System

2 Pages

-

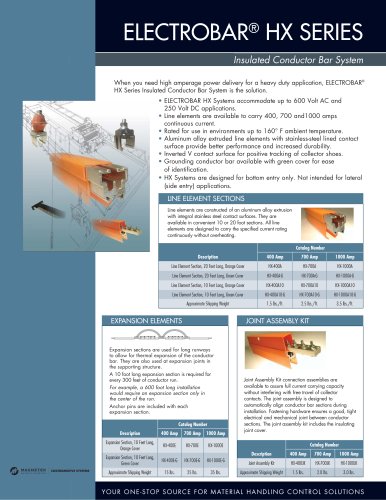

Electrobar HX Full Brochure

2 Pages

-

MAC.2000

2 Pages

-

Complete Control Panels

2 Pages

-

DataLogger Series 3+

1 Pages

-

OmniPulse DSD DC Controls

2 Pages

-

IMPULSE®?G+ Mini Brochure

6 Pages