Website:

Magnetek

Website:

Magnetek

Group: Columbus McKinnon

Catalog excerpts

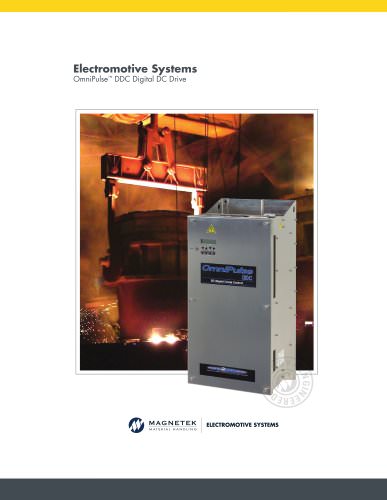

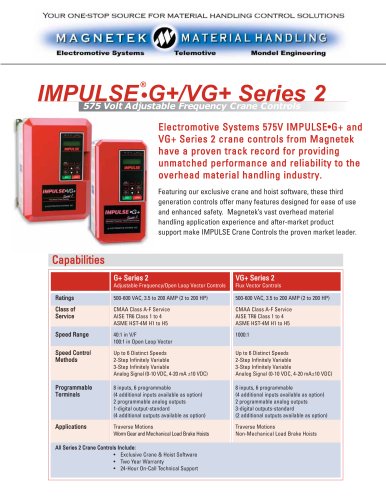

Digital DC Industrial Lifting Magnet Control Magnetek, the leader in crane and hoist motor control, offers the MagnePulse" Digital Magnet Control for the operation of DC industrial lifting magnets. Built on Magnetek's proven OmniPulse DDC platform, this microprocessor based, solid-state, DC-to-DC control combines advanced safety and performance features to improve productivity and reliability in your facility. ADVANCED PERFORMANCE • Digital control of the magnet's demagnetizing current means the magnet cleans the load faster and more consistently, increasing throughput • Exclusive OmniBeam™ feature allows the operator to enable any combination of up to four unique magnets to precisely match individual load requirements • Stepped current allows you to program the drive to lift/clean a single slab or a stack of slabs, reducing cycles and improving throughput • Power loss ride-through continues to energize the magnet to keep the control running and current flowing through the magnet when main power is lost IMPROVED SAFETY AND PROTECTION • MagnePulse DMC automatically removes magnet power during a fault event, preventing damage to the drive and magnet • Open/short circuit detection automatically disables current to the magnet if a cable is cut, avoiding control and magnet damage while improving plant safety • Over-temperature protection utilizes the magnet's resistance to determine its temperature, preventing magnet damage and increasing life expectancy • Digitally control the rate of current change to prevent voltage spikes or minimize drop time • Password protection stops unauthorized users from changing the control characteristics INCREASED PRODUCTION AND EFFICIENCY • Reduced lifting current maintains a full load while saving energy, lengthening magnet life, and increasing average lift capacity • Efficient use of energy reduces magnet heating up to 50%, reducing or eliminating the need for magnet change-outs • Flexible control options include single-input, dual-input, stepped-input, analog or serial current references as well as a programmable input to maximize magnet • Twenty-five drive, magnet and control status monitors check magnet current, voltage, resistance, temperature, DC bus voltage, and control variables to simplify process optimization ENHANCED PROGRAMMABILITY AND DIAGNOSTICS • Comprehensive software provides superior flexibility and allows for quick parameter changes — software upgrades can be flashed from a PC • Fully compatible with IMPULSE®»Link 4.1 Basic and IMPULSE'Link 4.1 Wireless Diagnostic System (WDS) allowing you to upload, download and monitor parameters using a hardwired or wireless link to your PC YOUR ONE-STOP SOURCE FOR MATERIAL HANDLING CONTROL SOLUTIONS

Open the catalog to page 1

MAGNETEK ElECTROMOTIVE SYSTEMS FLEXIBLE OPTIONS MagnePulse DMC can be easily retrofitted into your current framework, using existing operator controls and connections. Magnetek can also provide a pre-engineered panel with all the components needed to provide complete magnet control. Panel accessory options include E-stop, fan kits, and circuit breakers. MagnePulse DMC may also be added to a custom panel, designed and built to your exact specifications. Continuous Current Rating Input Voltage -1 0°C to 40°C (enclosed) at 60% duty cycle 1000 m maximum without derating For more information...

Open the catalog to page 2All Magnetek catalogs and technical brochures

-

ReFlx® 45 Brochure

1 Pages

-

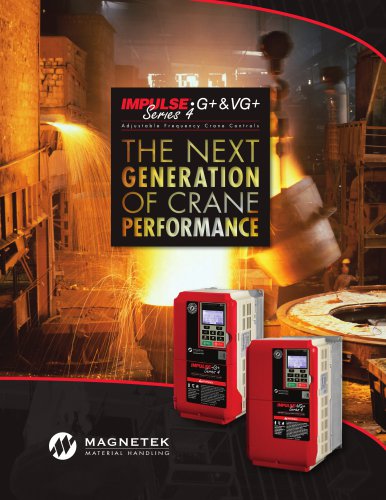

impulse_series_4

16 Pages

-

FLEX VUE Wireless Controls

2 Pages

-

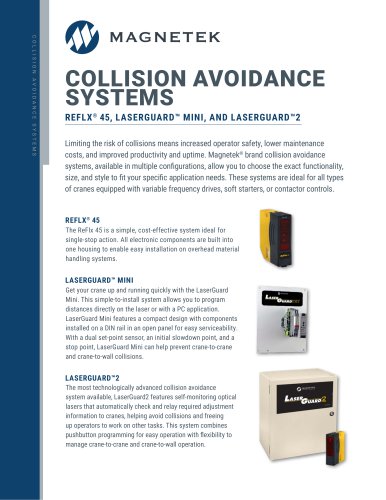

COLLISION AVOIDANCE SYSTEMS

2 Pages

-

Cable Reels Brochure

2 Pages

-

Magnetek Full Circle Service

6 Pages

-

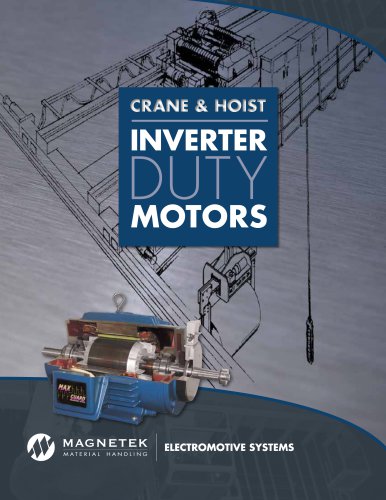

Black Max® Motors

4 Pages

-

IMPULSE®•T

2 Pages

-

DataLogger Series 4

1 Pages

-

IMPULSE®•G+ Mini

8 Pages

-

IMPULSE®•G+ Series 4

16 Pages

-

Engineered Systems & Solutions

16 Pages

-

Marine Terminal Family

8 Pages

-

Brake Accessories Brochure

2 Pages

-

Collision Avoidance Brochure

2 Pages

-

MH445_SBN

2 Pages

-

Enrange? Flex M Receiver

2 Pages

-

Enrange? CAN-6 Receiver

2 Pages

-

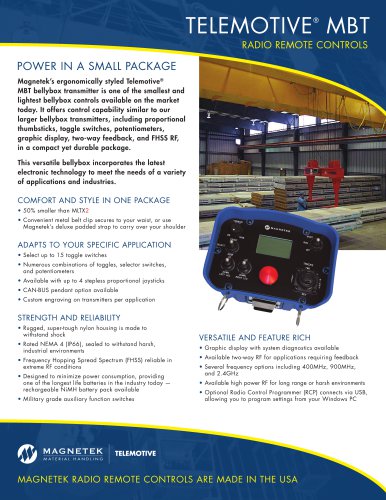

Telemotive MBT

2 Pages

-

Telemotive XLTX?

2 Pages

-

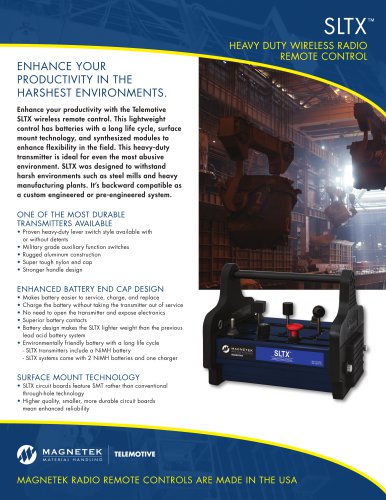

Telemotive SLTX?

2 Pages

-

Telemotive MLTX?

2 Pages

-

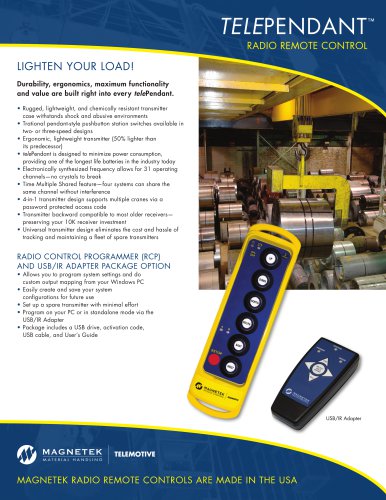

Telemotive telePendant?

2 Pages

-

Telemotive Flex VUE®

2 Pages

-

Enrange? Flex EX Series

2 Pages

-

OmniPulse? DSD DC Control

2 Pages

-

IMPULSE®?R

2 Pages

-

MAC??2000 Soft Starts

2 Pages

-

IMPULSE®?G+ Mini

6 Pages

-

IMPULSE®?G+ Series 4

16 Pages

-

Telemotive MLTX2?

2 Pages

-

Blue Max® Motors

6 Pages

-

IMPULSE®?T

2 Pages

-

ReFlx® 120

2 Pages

-

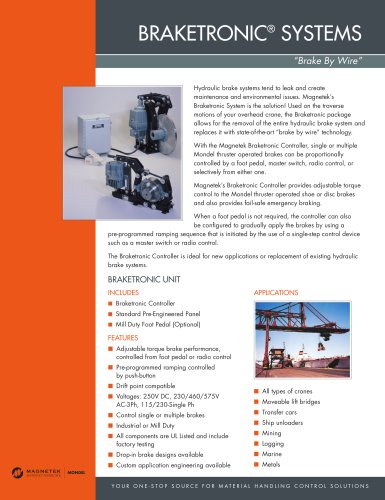

Braketronic®

2 Pages

-

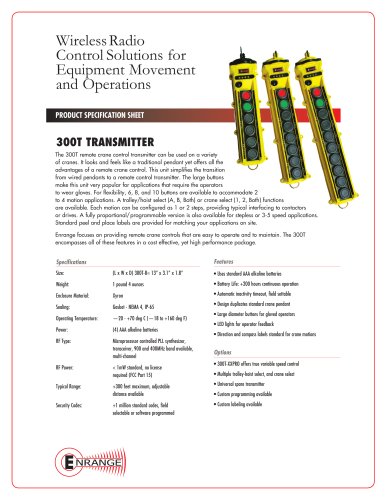

Enrange 300T

2 Pages

-

Telemotive telePendant

2 Pages

-

Enrange Flex Pro Series

2 Pages

-

Enrange Flex EX Series

2 Pages

-

Plug & Play Festoon System

1 Pages

-

Mill Duty I-Beam Festoon

6 Pages

-

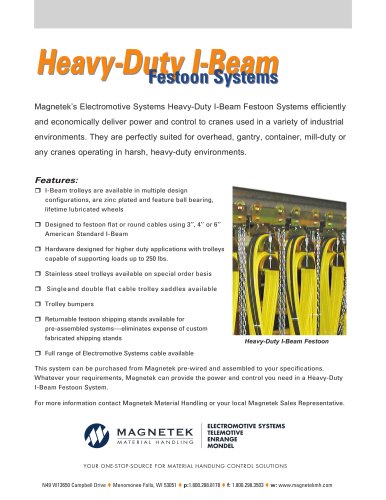

Heavy Duty I-Beam Festoon

4 Pages

-

C-Track Festoon Systems

4 Pages

-

FABA Conductor Rail System

2 Pages

-

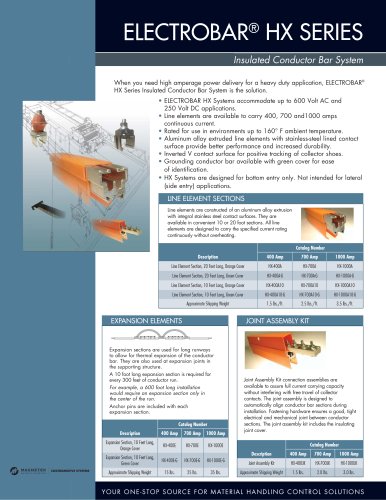

Electrobar HX Full Brochure

2 Pages

-

MAC.2000

2 Pages

-

Complete Control Panels

2 Pages

-

DataLogger Series 3+

1 Pages

-

OmniPulse DSD DC Controls

2 Pages

-

IMPULSE®?G+ Mini Brochure

6 Pages