Website:

Magnetek

Website:

Magnetek

Group: Columbus McKinnon

Catalog excerpts

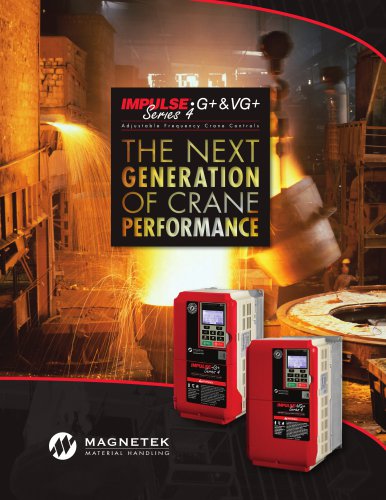

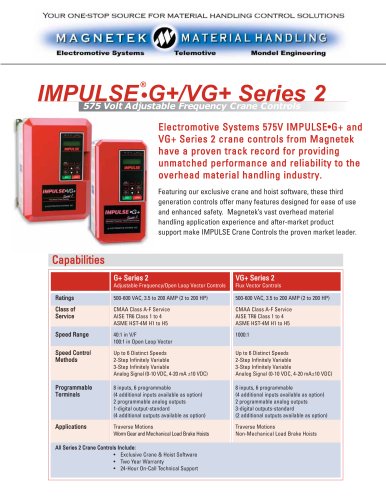

PULSE rG+&VG+ owes r

Open the catalog to page 1

THE NEXT GENERATION OF CRANE PERFORMANCE INDUSTRY-LEADING SAFETY AND PERFORMANCE FEATURES COMBINE WITH OUR SUPERIOR APPLICATION EXPERTISE TO PROVIDE UNMATCHED PERFORMANCE. IMPULSE drives are designed especially for material handling applications, providing a complete package of crane-specific capabilities far beyond a general purpose drive's functionality. Safety features are integrated into every drive, preventing harm to the crane structure and crane equipment, and most importantly, creating a safe working environment for operators. Magnetek's IMPULSE^G+/VG+ Series 4 drives continue our...

Open the catalog to page 2

INDUSTRY-LEADING PERFORMANCE FEATURES LOAD CHECK II ™ continuously detects hoist overload conditions, halting upward motion and only allowing the load to be lowered. Load Check II continuously monitors the hook load, both during acceleration and constant speed, eliminating the need for load cells in most applications. It provides an auto-setup function which defines the hoist’s maximum hook load in seconds. With these control advancements, the drive no longer pauses for tests unless rated capacity is approached, providing increased productivity. provides a redundant hardware safety circuit...

Open the catalog to page 3

Magnetek's custom control panels with IMPULSE^G+ and VG+ Series 4 drives provide the ultimate solution for overhead material handling. These panels are custom designed and built to your specifications to meet your exact application requirements. Our experienced engineering staff provides technical support and extensive overhead material handling expertise when quoting and designing your project. Custom panels are available with an unlimited number of configurations, components, and accessories. COMMON OPTIONS INCLUDE: • 120V control transformer and interface card1 • Brake contactor •...

Open the catalog to page 4

FEATURES SAFETY Brake Test* Anti-Shock* Encoder Loss Detection* Snapped Shaft Detection* Roll Back Detection/Torque Proving at Start/Brake Check at Stop* Safe Operating Windows Load Check II™ Quick Stop™ Slack Cable Detection Multi-Level Password Protection Phase Loss Detection Control Interface UL/cUL Rated Safe Torque Off Ground Fault Short Circuit Protection DC BUS Charge Indicator PERFORMANCE Indexing* Allows precise, programmed motor movement

Open the catalog to page 5

SPECIFICATION VALUE AND INFORMATION Certification UL, cUL, CSA, RoHS (CE available with filters) Rated input power supply volts and frequency 3-phase 200–240 VAC, 380–480 VAC, or 500-600 VAC; 50 or 60Hz Allowable input voltage fluctuation Control method Fully digital; sine-wave, V/F control, open loop vector control, flux vector control Maximum output voltage (VAC) Max output voltage 3-phase, 200/208/230/240/380/400/415/440/460/480/ 500/575/600V (proportional to input voltage) Rated output frequency (Hz) 0 to 150 Hz (consult factory for applications above 150 Hz) Output frequency accuracy...

Open the catalog to page 6

RATINGS 200-240 VAC, 3.0 to 415A (0.4 kW/0.75 HP to 110kW/150 HP) 380-480 VAC, 1.8 to 1090A (0.4 kW/0.75 HP to 560kW/900 HP) 500-600 VAC, 1.7 to 200A (0.75 kW/1 HP to 160 kW/200 HP) CLASS OF SERVICE CMAA Class A-F Service AISE TR6 Class 1 to 4 ASME HST-4M H1 to H5 SPEED RANGE 40:1 in V/F Mode (15 preset V/F Patterns, 1 Adjustable) 200:1 in Open Loop Vector Mode SPEED CONTROL METHODS Up to 17 Distinct Speeds (Stepped) 3-Step Infinitely Variable Analog Signal (0-10 VDC, 4-20mA, ±10 VDC) Digital Pulse Train Input (32kHz max) Radio Drive Serial Interface (RDSI) PROGRAMMABLE TERMINALS (8) 120...

Open the catalog to page 7

INTERFACE CARDS INPUT/OUTPUT OPTIONS (continued) Optically-isolated interface of 8 digital inputs (binary), 3 Form A dry contact digital outputs, 1 Form C dry contact fault output, 3 analog inputs, 2 analog outputs, pulse input and feedback, and RS-485 Modbus RTU interface. DIGITAL INPUT OPTIONS 120 VAC/50Hz & 60Hz 42-48 VAC/50Hz & 60Hz 24 VAC/50Hz& 60Hz 24 VDC ANALOG INPUTS (13 Bit + Sign) - Interface of 3 high resolution analog inputs to the drive. Signal levels (individually selectable): 0 to +/- 10 VDC (20kOhm) or 4 to 20mA (500 Ohm). Input resolution: Voltage (1/8192), Current...

Open the catalog to page 8

CONTROL OPTIONS NETWORK COMMUNICATIONS OPTIONS SINGLE ENCODER—LINE DRIVER Providing velocity and direction feedback from an encoder, this option is used for motor speed feedback in closed loop flux vector control. A 5 VDC buffered output is also included. Signal levels: 5 or 12 VDC differential line driver with compliments, maximum input frequency of 300kHz, phases A and B. Allowing for communication over 10/100Mbps Ethernet networks, this option has the ability to configure the IP address from a user specified IP address, from a DHCP host, or from a BootP host. All parameters, diagnostics,...

Open the catalog to page 9

DIAGNOSTICS AND DRIVE SUPPORT TOOLSIMPULSEHINK DIAGNOSTIC SOFTWARE • Parameter Management • Drive Monitor • DataLogger • Drive Trending Tool • Easily access Run, Alarm, and Fault histories, drive parameters, and drive trending data • View data and analysis via the LCD scrolling display or on your PC • Compatible with IMPULSE® Series 4, Series 3 and G+ Mini drives CRANE MONITORING IMPULSE G+/VG+ drives can be the cornerstone of an automated material handling system providing advanced diagnostic capabilities including: • Human Machine Interface (HMI) • Peripheral Equipment Interface •...

Open the catalog to page 10

CUSTOM APPLICATION SOFTWARE Our software will save you money by eliminating the need for a PLC or additional external logic. These software applications can be added to our already robust IMPULSE drives to meet your unique application requirements. FOOTBRAKE/STATIC STEPLESS SIMULATION SOFTWARE BUCKET CONTROL SOFTWARE WEIGHT MEASUREMENT SYSTEM (WMS) SOFTWARE DRIVE SYNCHRONIZATION SOFTWARE SWAY CONTROL SYSTEM (SCS®) SERIES 2 This software is designed for use on traverse motions to provide an effective means to slow or stop the motion of the bridge or trolley. Encoder feedback is used to...

Open the catalog to page 11

BUCKET CONTROL SOFTWARE SAVE TIME AND MONEY WITH OUR BUCKET CONTROL CUSTOM SOFTWARE This custom software can be used with IMPULSE•VG+ Series 4 drives to control multi-line clamshell or grapple buckets that utilize a loading/closing hoist. Although the open and hold drives operate independently, the software lets you control the various motions of the bucket without the need for a PLC. It features Bucket Position Indication, which provides the operator with the open/close status of the bucket while dredging (underwater) or when the bucket is not visible. This is done via analog output from...

Open the catalog to page 12All Magnetek catalogs and technical brochures

-

ReFlx® 45 Brochure

1 Pages

-

FLEX VUE Wireless Controls

2 Pages

-

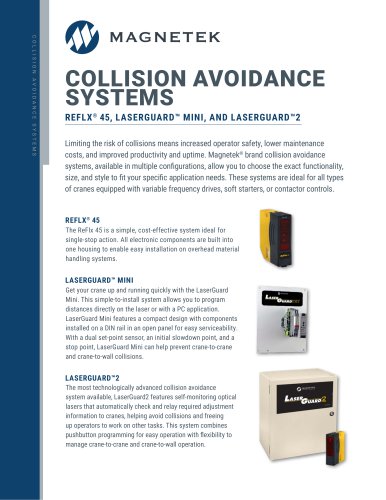

COLLISION AVOIDANCE SYSTEMS

2 Pages

-

Cable Reels Brochure

2 Pages

-

Magnetek Full Circle Service

6 Pages

-

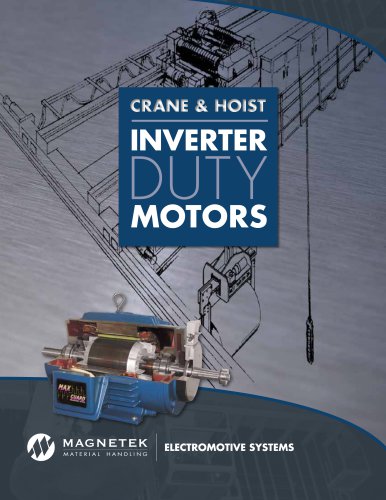

Black Max® Motors

4 Pages

-

IMPULSE®•T

2 Pages

-

DataLogger Series 4

1 Pages

-

IMPULSE®•G+ Mini

8 Pages

-

IMPULSE®•G+ Series 4

16 Pages

-

Engineered Systems & Solutions

16 Pages

-

Marine Terminal Family

8 Pages

-

Brake Accessories Brochure

2 Pages

-

Collision Avoidance Brochure

2 Pages

-

MH445_SBN

2 Pages

-

Enrange? Flex M Receiver

2 Pages

-

Enrange? CAN-6 Receiver

2 Pages

-

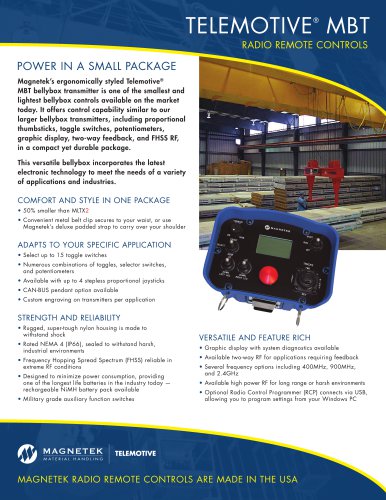

Telemotive MBT

2 Pages

-

Telemotive XLTX?

2 Pages

-

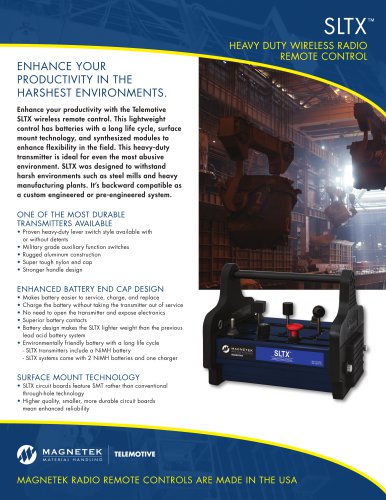

Telemotive SLTX?

2 Pages

-

Telemotive MLTX?

2 Pages

-

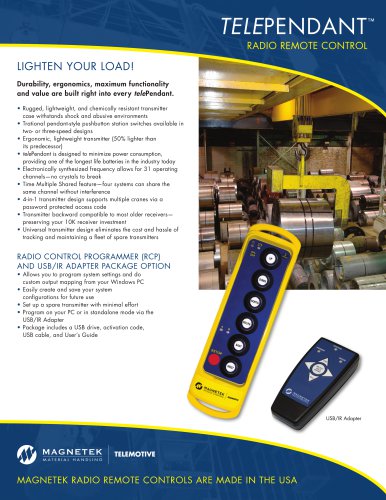

Telemotive telePendant?

2 Pages

-

Telemotive Flex VUE®

2 Pages

-

Enrange? Flex EX Series

2 Pages

-

OmniPulse? DSD DC Control

2 Pages

-

IMPULSE®?R

2 Pages

-

MAC??2000 Soft Starts

2 Pages

-

IMPULSE®?G+ Mini

6 Pages

-

IMPULSE®?G+ Series 4

16 Pages

-

Telemotive MLTX2?

2 Pages

-

Blue Max® Motors

6 Pages

-

IMPULSE®?T

2 Pages

-

ReFlx® 120

2 Pages

-

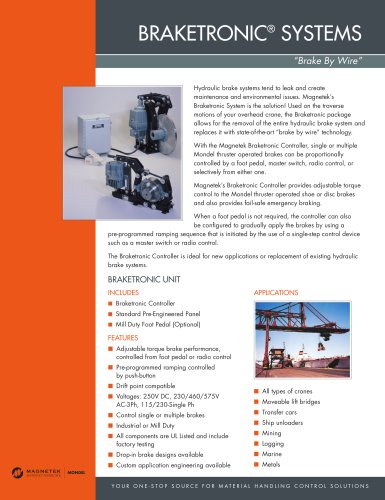

Braketronic®

2 Pages

-

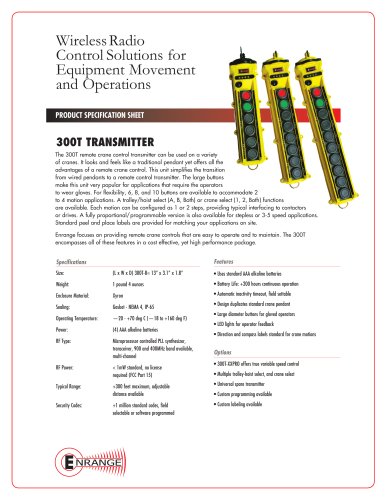

Enrange 300T

2 Pages

-

Telemotive telePendant

2 Pages

-

Enrange Flex Pro Series

2 Pages

-

Enrange Flex EX Series

2 Pages

-

Plug & Play Festoon System

1 Pages

-

Mill Duty I-Beam Festoon

6 Pages

-

Heavy Duty I-Beam Festoon

4 Pages

-

C-Track Festoon Systems

4 Pages

-

FABA Conductor Rail System

2 Pages

-

Electrobar HX Full Brochure

2 Pages

-

MAC.2000

2 Pages

-

Complete Control Panels

2 Pages

-

DataLogger Series 3+

1 Pages

-

OmniPulse DSD DC Controls

2 Pages

-

IMPULSE®?G+ Mini Brochure

6 Pages