Catalog excerpts

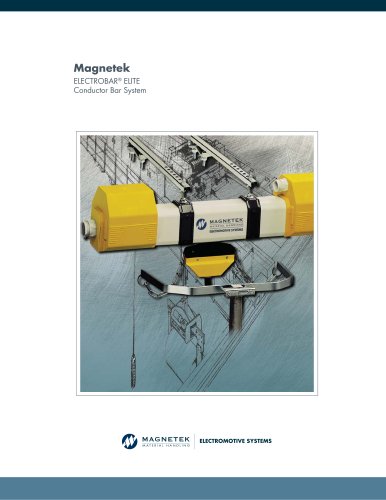

Magnetek ELECTROBAR® ELITE Conductor Bar System ELECTROMOTIVE SYSTEMS

Open the catalog to page 1

ELECTROBAR® ELITE ENCLOSED CONDUCTOR BAR SYSTEMS Magnetek proudly offers ELECTROBAR® Elite, our most advanced conductor bar system. The collector trolley and conductors are captured inside the line element extrusion and can't be disengaged. The collector trolley is advanced with a chain which tolerates large movements lateral to the direction of motion. The system is simple to install, with only one "stick" to hang and align. LOWER TOTAL SYSTEM COST - EASY TO INSTALL AND MAINTAIN • Electrobar Elite reduces installation time when compared with traditional conductor bar systems. Maintenance...

Open the catalog to page 2

STANDARD FEATURES & BENEFITS • Collector trolley captured by line element and can't be disengaged. • Snap together covers, power feeds and hangers. • Lightweight, rigid construction. • Ease of installation, lower total system cost, and low maintenance. • Improved safety (finger safe rating of IP23). • Line Elements are constructed of self-extinguishing PVC with copper conductors. 20 Amp Line elements use steel conductors. • Maximum rated operational voltage 600 volts, 460V for high temperature line elements. 4-POLE LINE ELEMENTS 5-POLE LINE ELEMENTS

Open the catalog to page 3

SYSTEM COMPONENTS Designed to feed power to the system either from the end or along the line element run. Allows for quick power connection with a snap together cover. Power feed selection based upon location and power feed cord diameter. END-LINE POWER FEED IN-LINE POWER FEED IN-LINE POWER FEED WITH JUNCTION BOX PRE-FABRICATED POWER FEED ON 1 METER LINE ELEMENT (NOT SHOWN) Catalog Number Self centering, snap-on joint cover, FM-2000 Joint Covering Flange for All Systems Weight Lbs. II Catalog Number prevent over travel

Open the catalog to page 4

SYSTEMS COMPONENTS Galvanized steel construction Snaps onto line element. SLIDING HANGER Anchor Hangers secure the line Galvanized steel construction with (2) anchoring screws. ANCHOR HANGER 8. HANGER MOUNTING BRACKETS FLANGE MOUNTING BRACKETS To order Flange Mount Brackets with two mounting clamps, add "A" after Fl 8 or F24. WORKSTATION BRIDGE CRANE MOUNTING BRACKETS

Open the catalog to page 5

COLLECTOR ASSEMBLIES 9. STANDARD (RIGID) COLLECTOR TROLLEY Collector selection based on amperage requirements. The collector assembly can be installed only in one orientation to the line element, insuring the ground conductor and the ground collector brush are always together. The brushes snap into the collector assembly for quick and easy replacement. Factory stocked collectors come standard with (1) meter of cable and are for systems without curves or dust protection. RIGID COLLECTOR TROLLEY RIGID COLLECTOR TROLLEY Collectors shown are for standard applications composed of straight line...

Open the catalog to page 6

DUST EXCLUSION SEALS 11. DUST EXCLUSION SEALS Rubber dust exclusion seals are available for line elements, in-line power feeds, joint covers, curves, trolley inlet gates and expansions. They are not used for end of line components, since the trolley does not pass through them. The catalog number is made by adding a -LV to the end of the standard catalog number. For example, a 20 Amp line element with dust exclusion seals is FM-4204-LV instead of the standard FM-4204. The seals can be added to stocked line elements, which allows good turnaround time for systems requiring dust exclusion....

Open the catalog to page 7

MATERIAL HANDLING ELECTROMOTIVE SYSTEMS Canada Facility Mississauga, Ontario EXPANSION ELEMENTS The expansion element is designed to absorb the difference in expansion between the support structure and the electrification line. Expansions are needed in 20 Amp applications longer than 460 Expansions are needed in 60 Amp and 100 Amp applications longer than 494 feet (150 meters). Expansions are needed in 130 Amp and 200 Amp applications longer than 820 feet (250 meters). When expansions are used, an extra single collector trolley must be used on each bridge. For more information, contact...

Open the catalog to page 8All Magnetek catalogs and technical brochures

-

ReFlx® 45 Brochure

1 Pages

-

impulse_series_4

16 Pages

-

FLEX VUE Wireless Controls

2 Pages

-

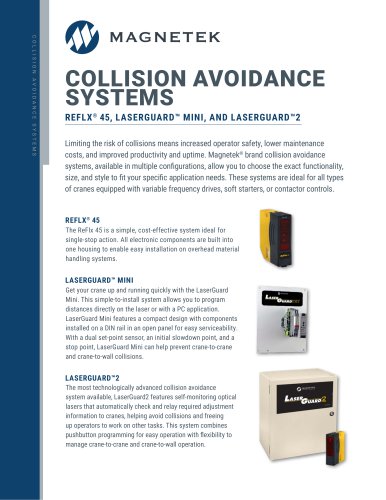

COLLISION AVOIDANCE SYSTEMS

2 Pages

-

Cable Reels Brochure

2 Pages

-

Magnetek Full Circle Service

6 Pages

-

Black Max® Motors

4 Pages

-

IMPULSE®•T

2 Pages

-

DataLogger Series 4

1 Pages

-

IMPULSE®•G+ Mini

8 Pages

-

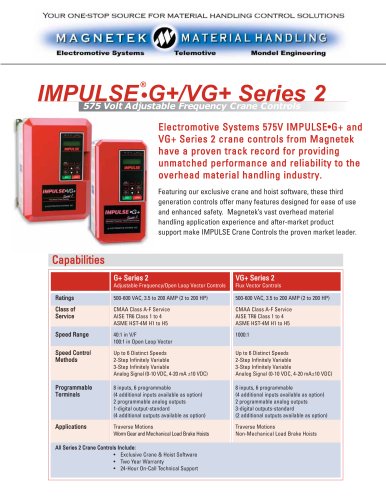

IMPULSE®•G+ Series 4

16 Pages

-

Engineered Systems & Solutions

16 Pages

-

Marine Terminal Family

8 Pages

-

Brake Accessories Brochure

2 Pages

-

Collision Avoidance Brochure

2 Pages

-

MH445_SBN

2 Pages

-

Enrange? Flex M Receiver

2 Pages

-

Enrange? CAN-6 Receiver

2 Pages

-

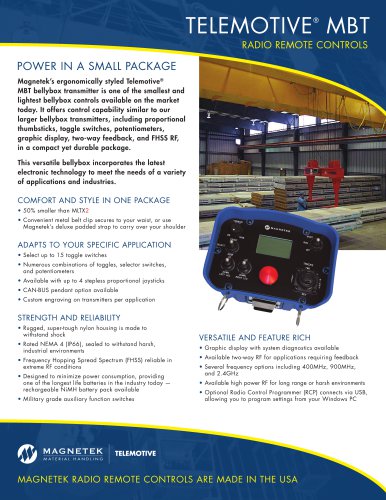

Telemotive MBT

2 Pages

-

Telemotive XLTX?

2 Pages

-

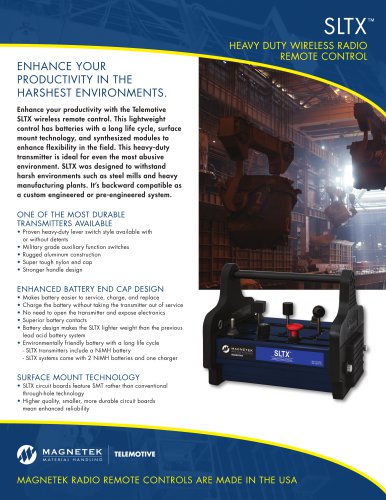

Telemotive SLTX?

2 Pages

-

Telemotive MLTX?

2 Pages

-

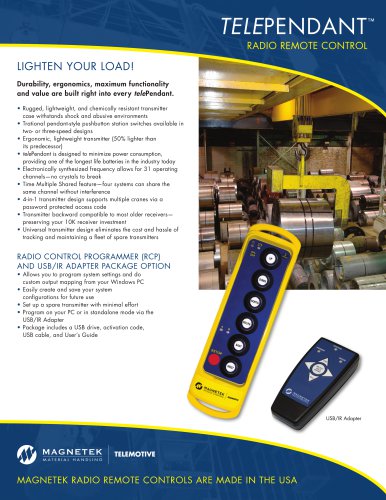

Telemotive telePendant?

2 Pages

-

Telemotive Flex VUE®

2 Pages

-

Enrange? Flex EX Series

2 Pages

-

OmniPulse? DSD DC Control

2 Pages

-

IMPULSE®?R

2 Pages

-

MAC??2000 Soft Starts

2 Pages

-

IMPULSE®?G+ Mini

6 Pages

-

IMPULSE®?G+ Series 4

16 Pages

-

Telemotive MLTX2?

2 Pages

-

Blue Max® Motors

6 Pages

-

IMPULSE®?T

2 Pages

-

ReFlx® 120

2 Pages

-

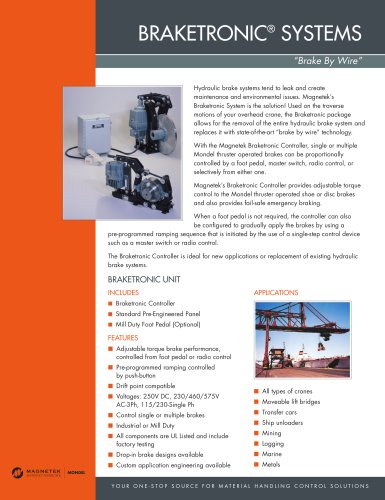

Braketronic®

2 Pages

-

Enrange 300T

2 Pages

-

Telemotive telePendant

2 Pages

-

Enrange Flex Pro Series

2 Pages

-

Enrange Flex EX Series

2 Pages

-

Plug & Play Festoon System

1 Pages

-

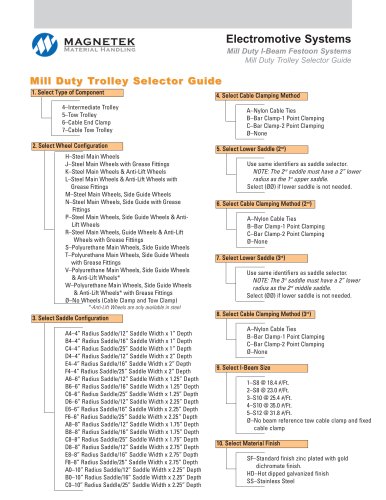

Mill Duty I-Beam Festoon

6 Pages

-

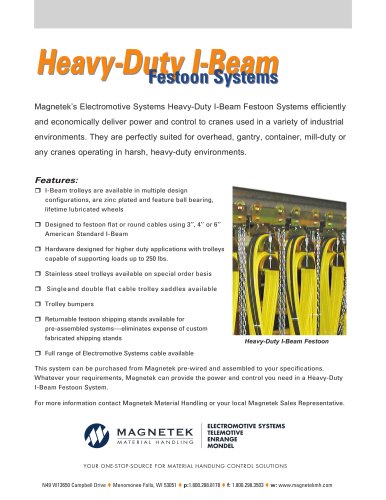

Heavy Duty I-Beam Festoon

4 Pages

-

C-Track Festoon Systems

4 Pages

-

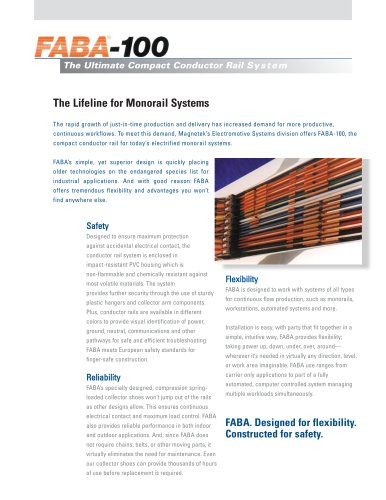

FABA Conductor Rail System

2 Pages

-

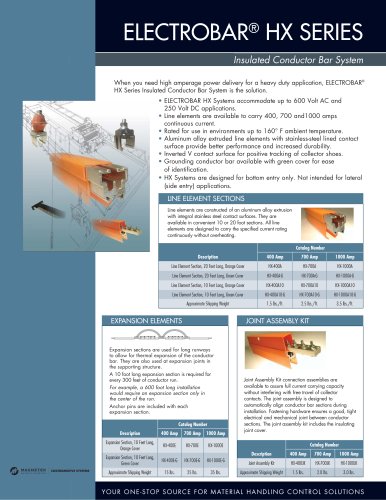

Electrobar HX Full Brochure

2 Pages

-

MAC.2000

2 Pages

-

Complete Control Panels

2 Pages

-

DataLogger Series 3+

1 Pages

-

OmniPulse DSD DC Controls

2 Pages

-

IMPULSE®?G+ Mini Brochure

6 Pages