Catalog excerpts

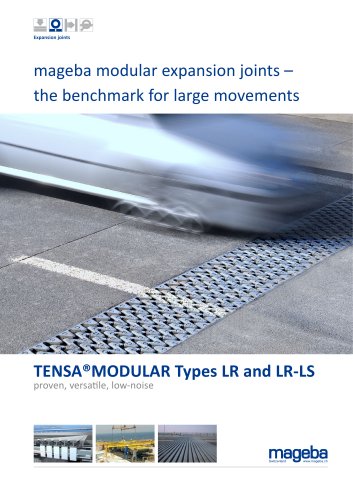

Expansion joints mageba modular expansion joints – the benchmark for large movements TENSA®MODULAR Types LR and LR-LS proven, versatile, low-noise Switzerland www.mageba.ch

Open the catalog to page 1

Expansion joints Product characteristics Principle Characteristics Parts and components TENSA®MODULAR expansion joints are based on the following concept: The movement gap at the end of a bridge deck is divided into smaller individual gaps by horizontal lamella beams. This enables deck movements of well over 2,000 mm to be accommodated. Rotations about every axis can also be facilitated. Expansion joints are subjected to considerable demands and must satisfy these over a service life of many years. The design of the watertight TENSA®MODULAR expansion joint, which was invented by mageba, has...

Open the catalog to page 2

Expansion joints Client benefits Highlights • Allows free movements in all directions and rotations about every axis • Completely watertight system with drainage at the bridge surface • Versatile and freely adaptable to suit client‘s wishes • Can be used on all types of bridges • Based on well-proven and thoroughly tested components and parts • Low-noise when fitted with sinus plates Design Functionality • Welding is avoided in all highly stressed connections, increasing durability. • All parts of the joint are elastically prestressed, making them highly resistant to fatigue. • All of the...

Open the catalog to page 3

Expansion joints Movement capacity Movements of the joint Skewed orientation and movements mageba TENSA®MODULAR expansion joints allow movements in every direction and, at the same time, rotations about every axis. Their elastic control system can accommodate large transverse and vertical movements without developing constraint forces. Expansion joints are typically installed perpendicular to the bridge’s axis, with their longitudinal movements parallel to the same axis. But it is also possible to design modular joints for installation with a different orientation (i.e. not perpendicular to...

Open the catalog to page 4

Expansion joints Design details Support and connection system Control system The joint’s lamella beams are connected to the support bars beneath by stirrups through which the support bars pass. In the same way, the support bars are enclosed by support bar boxes at the edges of the joint. In this way, the whole system is supported and connected elastically and securely, while still allowing movements as desired. Elastomeric springs control the movements of the individual lamella beams and make them work as a single kinematic system. The movements of each lamella beam relative to its...

Open the catalog to page 5

Expansion joints Testing & optional features Laboratory testing The TENSA®MODULAR expansion joint has proven its worth in testing by indepen- dent institutions on many occasions. For example, the durability of the joint was verified in testing with 6 x 106 load chan- ges, after which no signs of fatigue could All critical components and their materials, such as elastomers and sliding surfaces, were also subjected to individual testing. In an Opening Movement & Vibration (OMV) test as defined by American stan- dards, the joint proved its suitability in a programme which simulated a 100-year...

Open the catalog to page 6

Expansion joints Materials & installation Materials Installation The following high-quality materials in particular are used as standard for the manufacturing of TENSA®MODULAR expansion joints: In particular, the installation of very large TENSA®MODULAR expansion joints should be supervised by a mageba specialist. Before installation, the bridge gap width and temperature are checked by the contractor, and the joint’s presetting value is adjusted as appropriate. The joint is then levelled against both edge profiles. • Lamella beams and support bars of S355 steel; hybrid lamella beams...

Open the catalog to page 7

Expansion joints Quality & support Related products Quality The following mageba products can be used in combination with TENSA®MODULAR expansion joints: The 100% watertight modular expansion joint was invented by mageba in the 1960s. For five decades, mageba TENSA®MODULAR expansion joints have proven their worth in thousands of structures under the most demanding conditions. In addition to the product properties, the extensive experience of our well-qualified manufacturing and installation staff also contributes to the product’s high quality and durability. • ROBO®DUR: Strengthening ribs...

Open the catalog to page 8All Mageba catalogs and technical brochures

-

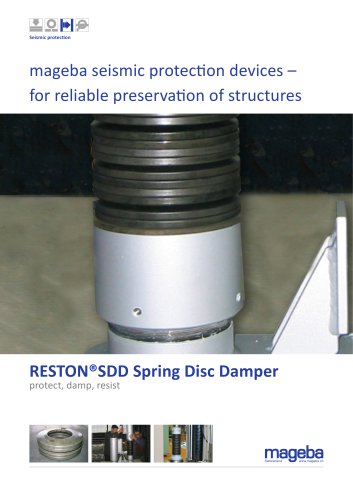

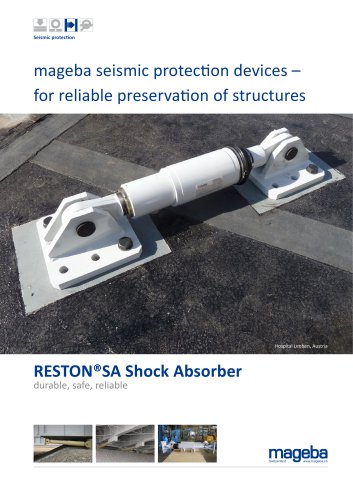

RESTON®SDD

2 Pages

-

RESTON®LINEAR

2 Pages

-

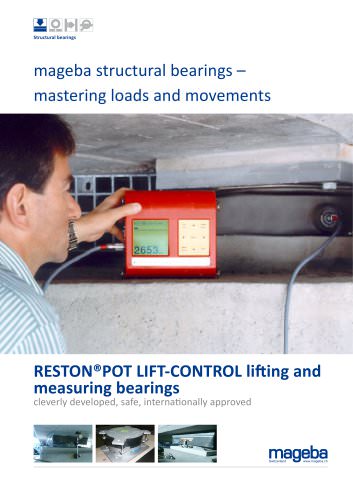

RESTON®POT LIFT-CONTROL

4 Pages

-

LASTO®BLOCK

4 Pages

-

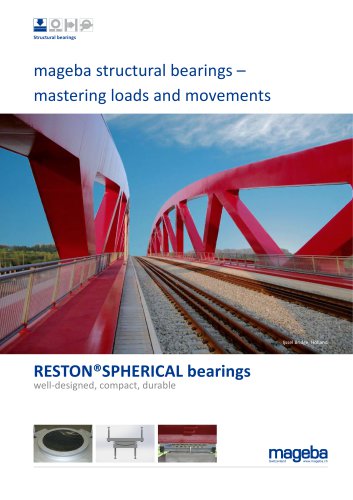

RESTON®SPHERICAL

4 Pages

-

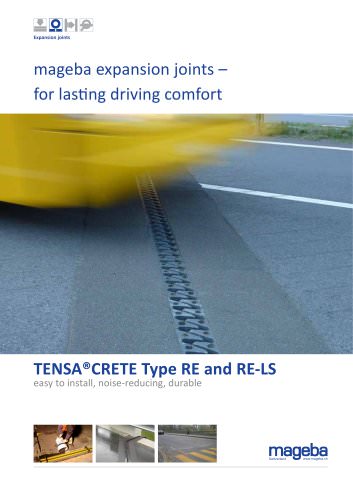

POLYFLEX®Advanced PU

8 Pages

-

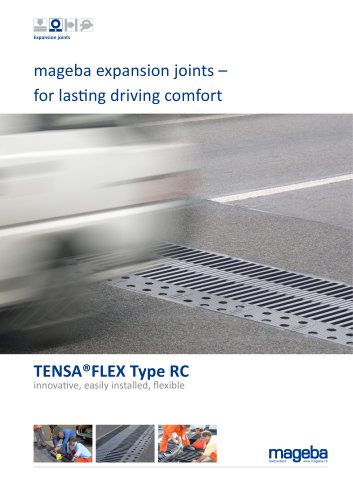

TENSA®RAIL RSU

2 Pages

-

TENSA®MAT RM

2 Pages

-

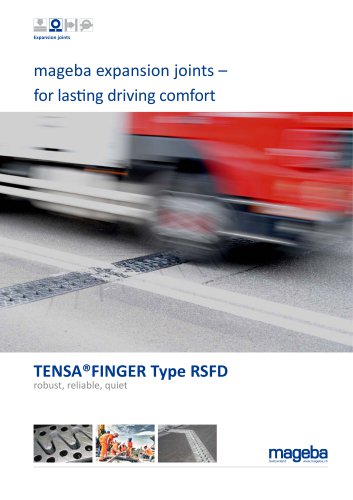

TENSA®FINGER GF

4 Pages

-

Prospectus seismic isolators

4 Pages

-

Prospectus spherical bearing

4 Pages

-

Product brochure RESTON®POT

4 Pages

-

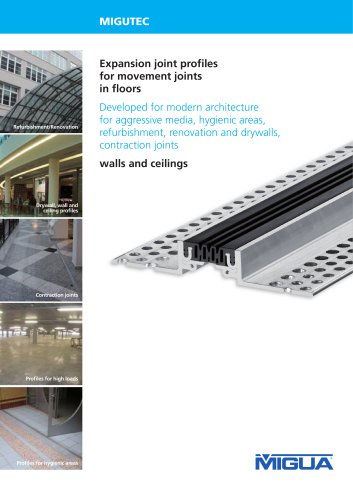

Prospect MIGUTEC

72 Pages

-

Prospect LASTO®STRIP

6 Pages

-

Prospect LASTO®WALL C

4 Pages