Catalog excerpts

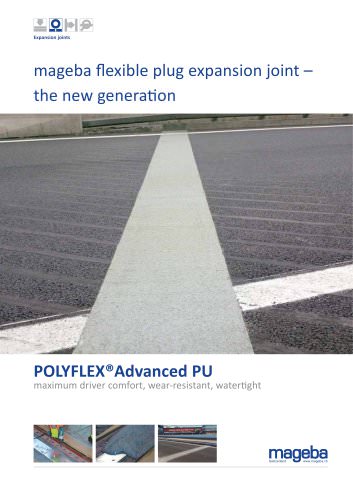

Expansion joints mageba flexible plug expansion joint – the new generation maximum driver comfort, wear-resistant, watertight

Open the catalog to page 1

Expansion joints Product Characteristics Principle The new POLYFLEX®Advanced PU Flexible Plug Expansion Joint System achieves a completely new standard in terms of quality and working life. The POLYFLEX®Advanced joint uses a durable fully elastic material with an enormous tear resistance and low reaction forces. Perforated steel angles within the PU-material help to accommodate horizontal braking and reaction forces and allow for a clean bond between surfaces free of leakages from ingressing water. Compared to other expansion joint designs, flexible plug expansion joints offer several...

Open the catalog to page 2

Expansion joints Client Benefits Advantages & Properties Damage Repair & Partial Installations • Exceptional long working life, longer than adjacent urfaces s Traffic accidents or road maintenance vehi cles such as snowplows can cause damage to traditional expansion joints leading to high repair costs. • Highest possible driver comfort • No noise from crossing traffic due to s urface that is flush with adjacent road • Watertight • Maintenance free (continuous cleaning as with traditional steel joints not required), • Suitable for new structures and refurbish- ments • Quickly installed...

Open the catalog to page 3

Expansion joints Design Details & Movement Capacity Design Principles traffic safety as well as for a perfect driver comfort. cent surfacing so as to prevent the asphalt from being depressed into the sides of the joint material. The POLYFLEX®Advanced PU filling material shows excellent adhesion to the supporting structure as well as to the adjacent surfacing, and is therefore capable of safely transferring horizontal loads to the structure. The waterproofing membrane of the structure is integrated into the joint filling material or the polymer concrete bedding material for the substructure...

Open the catalog to page 4

Expansion joints Testing and Verification Wheel tracking comparison test A wheel tracking test according to EN 12697-22 was performed by the Testing Institute MAPAG in August of 2009. Testing was done on two different flexible plug joint systems with the following results: Estimation of working life: conventional asphaltic plug expansion joints (picture ①) BT 16 HS LKS (common asphaltic surfacing) POLYFLEX®Advanced PU (picture ②) In practice, this means that the expected working life for POLYFLEX®Advanced PU fle- xible plug expansion joints will be more than 2 times higher than the working...

Open the catalog to page 5

Expansion joints Testing and Verification Movement Capacity Test & Material Characteristics test At the Federal Institute for Materials Research and Testing (BAM) in Berlin, Germany, movement capacity tests according to ETAG 032-3, Annex 3-N have been carried out on a test sample of a PA 50 POLYFLEX® Advanded PU expansion joint. During test method a) “Movement capacity under slow occurring movements“, the temperature of the specimen was controlled according to the applied movements. Therefore, the maximum tension of 33 mm was applied at –40 °C (-40 °F) and the maximum compression of 17...

Open the catalog to page 6

Expansion joints Materials & Installation Material Description POLYFLEX®Advanced PU is an elastic, solvent-free 2-component grout system developed for the application of flexible plug expansion joint systems. Technical data of PU material*) density hardness shore A according to DIN 53505 tensile strength according to DIN 53504 recommended substrate temperatures The polymer concrete recommended for the support is a cold processed grout system adapted to the POLYFLEX®Advanced PU joint in terms of workability and endurance. elongation at break according to DIN 53504 tear strength according to...

Open the catalog to page 7

Expansion joints Quality & Support Consulting mageba offers full technical support to help determine the proper joint width and details with consideration of all technical and economic aspects in order to calculate the optimum and most cost-effective solution. For new structures, the bituminous surfacing shall be made in advance. For concrete surfacing and at edge beams, adequate recesses shall be provided. If the joint is installed upon a concrete support, the minimal nominal compressive strength must be 25 N/mm². POLYFLEX®Advanced PU flexible plug expansion joints can be installed either...

Open the catalog to page 8All Mageba catalogs and technical brochures

-

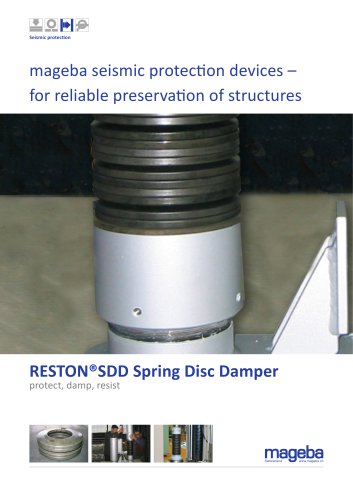

RESTON®SDD

2 Pages

-

RESTON®LINEAR

2 Pages

-

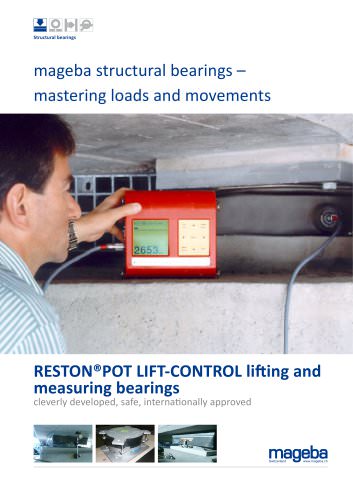

RESTON®POT LIFT-CONTROL

4 Pages

-

LASTO®BLOCK

4 Pages

-

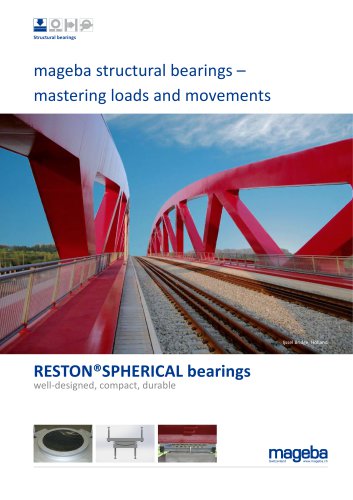

RESTON®SPHERICAL

4 Pages

-

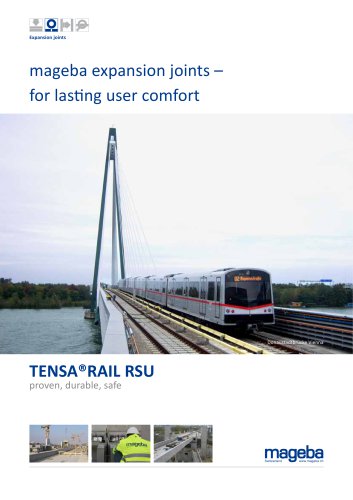

TENSA®RAIL RSU

2 Pages

-

TENSA®MAT RM

2 Pages

-

TENSA®FINGER GF

4 Pages

-

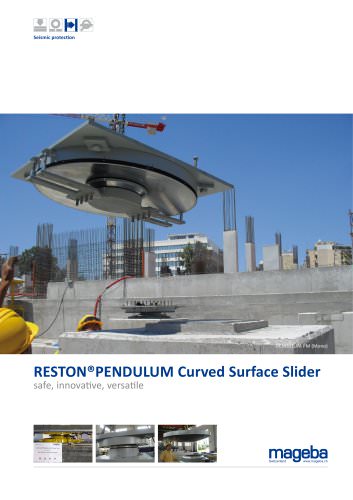

Prospectus seismic isolators

4 Pages

-

Prospectus spherical bearing

4 Pages

-

Product brochure RESTON®POT

4 Pages

-

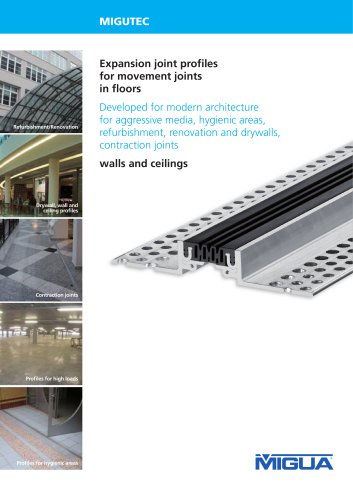

Prospect MIGUTEC

72 Pages

-

Prospect LASTO®STRIP

6 Pages

-

Prospect LASTO®WALL C

4 Pages