Catalog excerpts

A member of the UNITED GRINDING Group PROFIMAT MT Profile grinding with increased profitability Key data Blindtext United Grinding Technologies velia si dolupta The PROFIMAT MT – fi nsequis Technologies Secaeriorst-class grinding technology for repelit, natum tioatur? Tiatiamprofile grinding.quiae verorum id Secaerio nsequis velia si doluptaconsequiTiatiam ut aut atenfddi arund aaeces nis tioatur? corest • 6 machine quiae verorum id ut aut atenfddi repelit, natum sizesad venectus dolorest, sunt erum faciis sero et arund aaeces nis consequi corest kW ommoluptat. Etwa recab cepe ribus, omnia dolor• Grinding spindle drive up to 60erum faciis sero et ad ioreo speedmagnien tionsectis atendi rorMax. wheel doltio of 170 m/s ommoluptat. • sitatat venectus dolorest, sunt Etwa recab cepe ribus, omnia dolorror sitatat aruneces dolo coresteruvenectus dolorest, sunt ioreo doltio magnien tionsectis atendi aruneces ommolupt. dolo coresteruvenectus dolorest, sunt

Open the catalog to page 1

Blohm Jung GmbH Productivity, performance and precision – three attributes which users worldwide associate with surface and profile grinding machines from BLOHM and JUNG. Our machines have been in use worldwide for decades in widely varying fields of application and under very different conditions. The experience gained from over 35,000 delivered machines is constantly incorporated into further developments and innovations, increasing our customers' production efficiency even further. The product portfolio of Blohm Jung GmbH extends from surface grinding machines through applicationoriented...

Open the catalog to page 2

Characteristics Dimensions Modular system High quality components comprising gray cast iron Thermal and vibration engineering characteristics optimized via finite element analysis Precison linear guideways High quality, recirculating ballscrews Siemens 840D solution line with safety functions Optimal operator guidance Programming with menu-guided grinding and dressing cycles 6 machine sizes with grinding ranges from 400 x 800 mm to 600 x 2,000 mm Grinding spindle speed (rpm) Grinding spindle drive power curves The BLOHM PROFIMAT MT line has been designed purely as a high performance...

Open the catalog to page 3

Well-proven – the design principle Process optimized accessories Vertical auxiliary grinding spindle for universal use in the mould and die industry with a power of up to 6 kW and up to 90,000 rpm The modular platform concept with high-grade components made of cast iron is thermal and vibration optimized using 3D-CAD and finiteelement analysis. Selected components guarantee high precision and long life. Horizontal auxiliary grinding spindle, automatically positioned in the working area, for the back-off grinding on broach tools using a min. wheel diameter of 30 mm Measuring probe,...

Open the catalog to page 4

Optimal dressing The comfortable solution for profile grinding applications The best machines in a performance class offer more than just technically advanced components. Their high capabilities are made possible by the use of perfectly matched software and technology. The CNC control Siemens Sinumerik 840D solution line with graphical operator guidance especially developed for grinding applications guarantees an optimal process. The simple programming is supported by menu guided grinding and dressing cycles. The software option GripsProfile is a comfortable tool, especially for the single...

Open the catalog to page 5

BLOHM Solutions Automotive industry and suppliers Roller for diesel injection pump Turbine industry Housing for diesel injection pumps Turbine vane – 5 axes continuous path controlled Turbine blade grinding Root profile Steering racks Compressor blade – multiple operations in one set-up Shroud segment – multiple operations in 1 set-up Root and shroud profile

Open the catalog to page 6

BLOHM Solutions Tool and die industry Machine building Tooth rack Transfer drum

Open the catalog to page 7

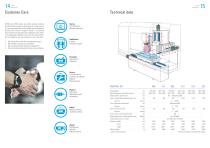

Customer Care BLOHM and JUNG surface and profile grinding machines should fulfill the customers requirements for as long as possi- ble, work cost-effectively, function reliably and be available at all times. From "start up" through to "retrofit" - our Customer Care is there for you throughout the working life of your machi- ne. 6 professional helplines and more than 25 service technici- ans are available in your area, wherever you are in the world. • We will provide you with fast, uncomplicated support. • We will help to increase your productivity. • We work professionally, reliably and...

Open the catalog to page 8

KORBER SOLUTIONS KORBER SOLUTIONS Blohm Jung GmbH Location Hamburg Location Goppingen Partner of the Engineering Industry Sustainability Initiative

Open the catalog to page 9All MÄGERLE AG Maschinenfabrik catalogs and technical brochures

-

MFP 50

11 Pages

-

MFP 30

16 Pages

-

MFP51

11 Pages

-

Product program

32 Pages

-

MAEG UEBERSICHT

32 Pages

-

PROFIMAT_MC_RT

9 Pages

-

UNITED GRINDING Group

35 Pages

-

MFP50

11 Pages

-

KRONOS

12 Pages

Archived catalogs

-

MÄGERLE GRINDING SYSTEMS_2019

36 Pages

-

MFP 100_2013

9 Pages

-

MÄGERLE GRindinG SyStEMS_2013

17 Pages

-

MFP 100

2 Pages