Catalog excerpts

A member of the UNITED GRINDING Group MFP 51 Maximum productivity for complex components Key Data Portal tool magazine Simultaneous tool & dresser roll changer Process-optimized coolant supply Tool identification

Open the catalog to page 1

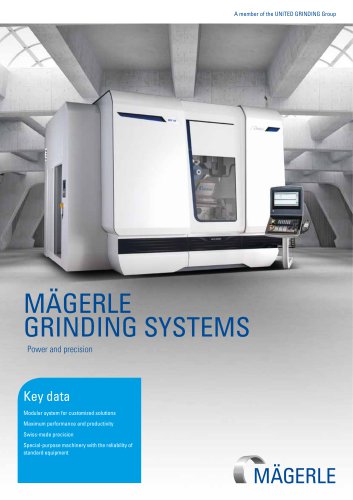

MFP 51 Mägerle AG Maschinenfabrik Precision, quality and flexibility are key attributes of the products manufactured by Mägerle AG Maschinenfabrik. A technology leader for highperformance surface and profile grinding systems, the company founded in 1929 primarily specializes in customized solutions. At the heart of the international success of our high-quality Swiss machinery is the unique design principle of the MÄGERLE modular system. Thanks to state-of-the-art technology, MÄGERLE can offer customers from many branches of industry reliable grinding centers. The high machining precision of...

Open the catalog to page 2

• X-axis - longitudinal stroke: 500 mm • Tool changer with 66 positions • Y-axis - vertical stroke: 650 mm • Simultaneous tool and dressing roll changer • Z-axis - transverse stroke: 650 mm • Automatic nozzle changer • Tool identification system • Continuous power grinding wheel drive: 25/50 kW • Spindle speeds up to 12,000 rpm • 5 or 6-axis system • Grinding, milling and drilling in a single clamping • Pre-programmed grinding and dressing cycles • User-specific programmable interface • Intuitive operation • Focus on work and production...

Open the catalog to page 3

Machine Configuration Large Magazine for Tools Efficient machining of a variety of workpieces Example 1: 21 grinding wheels 21 dressing rolls 7 tools Example 2: 28 grinding wheels including sister tools 14 dressing rolls Example 3: 37 CBN grinding wheels with maximum diameter The tool magazine for grinding wheels, diamond rolls and tools comes in a gantry design with 66 positions. All tools are transferred to the magazine safely and ergonomically by means Flexible loading options ❶ Tool magazine ❷ Loading station with optional tool identification ❸ NC indexing head ❹ Dressing device ❺...

Open the catalog to page 4

Application Examples and Machining Capabilities Turbine vanes Compressor blades Compressor blades for aircraft engines are manufactured from forgings, which comprise high-strength and in some cases also heat-resistant material alloys. The complete blade root profile is produced in a single clamping. The machine configuration with a 3-axis indexing head also enables the machining of radial root profiles. Shrouds Shrouds can be completely machined in just a few clampings on the MFP 51, including milling and drilling operations. Each individual machining process can be optimized with different...

Open the catalog to page 5

The Right Dressing Method Hydrostatic System and Powerful Drives Dressing system Wear-free guide concept ➍ ❶ Grinding support with ❷ Diamond dressing roll ❸ Grinding wheel The unique design principle of MÄGERLE machining centers forms the basis for the overall machine quality. The vertical axis is supported by hydrostatic wrap-around guideways on a thin oil film and is completely separated from the column upper section. This principle enables the machines to withstand very high stresses free of wear, even in long-term use. The oil film also has a vibration-damping effect and guarantees...

Open the catalog to page 6

Cooling Intelligence Coolant Cleaning Units Optimal grinding and machining results The optimal solution for every application The NC controls of the MÄGERLE grinding centers enable precise positioning of the coolant supply, taking into account the respective grinding wheel geometry. Nozzles are available on the grinding support for drilling and milling tools, and a coolant supply can be optionally provided through the spindle. Additional separate nozzles for the dressing process and cleaning of the grinding wheels ensure that optimal grinding results are achieved. Labyrinth seals with a...

Open the catalog to page 7

Safe and Autonomous Operation Control Systems Tool identification Operational safety and user-friendliness in the center The MFP 51 can optionally be equipped with an identification system for grinding wheels and tools. The tool is inserted in the loading station of the tool changer. The data stored on an RFID chip is securely imported prior to the loading process. When the grinding wheel is removed from the tool magazine, the system updates the chip with the current tool data. This eliminates the probability of errors when entering the tool data on the machine and consequently also the...

Open the catalog to page 8

Ease of Operation and Maintenance Customer Care The machine is operated via the swiveling control panel with a view of the working area in the front of the machine. When the splash guard is opened, heavy workpieces including clamping fixtures can also be loaded from the top with a gantry or jib crane. The tools are provided to the tool changer via a separate loading station. ❶ Working area ❷ Splash guard opened at the top MÄGERLE surface and profile grinding machines should fulfill the customer's requirements for as long as possible, work cost-effectively, function reliably and be available...

Open the catalog to page 9

MAGERLE MFP 51 Layout Technical DataMFP 51 Machine configuration Technical data for MFP 51 O Working area Q Quick-change spindle for machining tools @ Quick-change spindle for diamond dressing rolls O Automatic coolant nozzles 0 NC indexing head 2/3 axes © Dressing device O Dual gripper 0 Tool loading station with tool identification Q Tool change magazine © Input station for tool management 0 Interface to coolant processing system © Interface to cooling system for spindle drives © Hydrostatic/Hydraulic unit © Centralized lubricating system © Electrical cabinet © Mist extractor...

Open the catalog to page 10All MÄGERLE AG Maschinenfabrik catalogs and technical brochures

-

MFP 50

11 Pages

-

MFP 30

16 Pages

-

Product program

32 Pages

-

MAEG UEBERSICHT

32 Pages

-

PROFIMAT_MC_RT

9 Pages

-

PROFIMAT MT

9 Pages

-

UNITED GRINDING Group

35 Pages

-

MFP50

11 Pages

-

KRONOS

12 Pages

Archived catalogs

-

MÄGERLE GRINDING SYSTEMS_2019

36 Pages

-

MFP 100_2013

9 Pages

-

MÄGERLE GRindinG SyStEMS_2013

17 Pages

-

MFP 100

2 Pages