Catalog excerpts

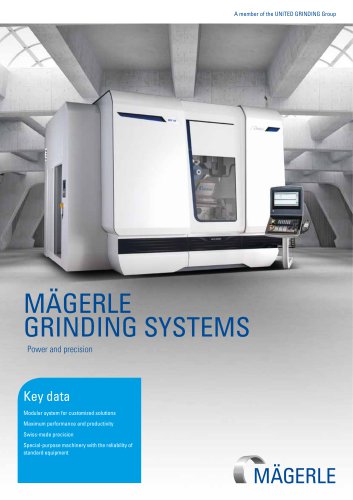

A member of the UNITED GRINDING Group MFP 50 Highly flexible for demanding applications Key data Maximum performance and productivity Swiss-made precision Wide variety of tools and process flexibility Compact layout

Open the catalog to page 1

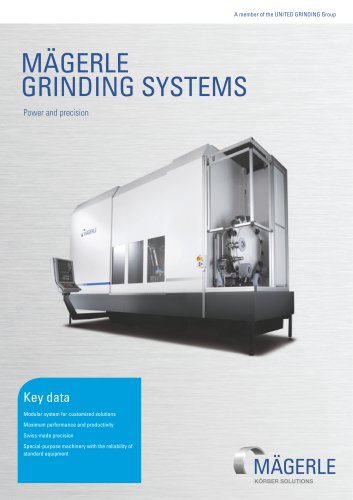

MFP 50 Mägerle AG Maschinenfabrik Precision, quality and flexibility are key attributes of the products manufactured by Mägerle AG Maschinenfabrik. A technology leader for highperformance surface and profile grinding systems, the company founded in 1929 primarily specializes in customized solutions. At the heart of the international success of our high-quality Swiss machinery is the unique design principle of the MÄGERLE modular system. Thanks to state-of-the-art technology, MÄGERLE can offer customers from many branches of industry reliable grinding centers. The high machining precision of...

Open the catalog to page 2

Dimensions Hardware Software • Grinding spindle drive power: 25/50 kW *5 or 6-axis system • X-axis - longitudinal stroke: 500 mm • Axis travel speed up to 30,000 mm/min • Y-axis - vertical stroke: 650 mm • Grinding, milling and drilling in a single clamping • Z-axis - transverse stroke: 650 mm • Wear-free hydrostatic guideways • Water-cooled drive • User-specific programmable interface • Innovative control architecture • Intuitive operation • Focus on work and production safety The MAGERLE MFP 50 combines flexibility and performance in a compact design. As a 5 or 6-axis system, this CD...

Open the catalog to page 3

Machine Configuration Hydrostatic and Powerful Grinding Wheel Drives Wear-free guideway concepts The whole quality of the MÄGERLE Grinding Centers is based on the unique design principle. The vertical axis is equipped with hydrostatic wrap-around guideways and completely separated from the upper part of the column by a thin oil film. Integrated oil chambers keep the process stable, irrespective of thermal fluctuations. As a result MÄGERLE grinding machines can withstand high loads without signs of wear - even in long-term use. The oil film has a vibration-damping effect and guarantees...

Open the catalog to page 4

Application Examples and Machining Capabilities Turbine stator and rotor vanes Hirth coupling ring Leit-und Laufschaufeln werden an der MFP 50 mit minimalen Stillstandzeiten geschliffen. Die Kombination von automatischem 24-fach Werkzeugwechsler und CD-Überkopfabrichten ermöglicht in einer Werkstückaufspannung mehrere Flächenprofile zu schleifen und die Masshaltigkeit zu sichern. Complete machining on Hirth coupling rings with an additional spindle in a special design, enables the gear tooth profiles as well as ex- which enables additional bore grinding with ternal and internal diameter to...

Open the catalog to page 5

Tool Change System for Demanding Applications The Right Dressing Method MFP 50 dressing system The dressing of the grinding wheels is a crucial factor for the efficiency of the grinding process. With overhead and table dressing devices, MÄGERLE provides professional solutions for the various requirements of this process step. The potential of the overhead principle is developed in continuous dressing (CD) and inprocess dressing (IPD). Table dressing devices are used for fixed or rotating dressing tools, where the rotating ad ad principle produces optimal results in diamond full form...

Open the catalog to page 6

Cooling Intelligence Coolant Cleaning Units Perfect protection of the machining area, long working life of the entire system The optimal solution for every application Endless belt with brush-of device Filter cake Inlet box Vacuum pump Filtering phase Filter cake Belt drive Blow-off device Drying area Brush-of device Scraper Reverse flushing device Endless belt Filter fleece with take-up unit Sludge container Filter cake Delivery pump Scraper worm Filter fleece Sludge tank Cost-saving cooling intelligence The NC systems currently used in MÄGERLE Grinding Centers allow precise positioning of...

Open the catalog to page 7

Efficient Automation Automation and machining cells Example machining cell 2 The MFP 50 is ideally suited for automatic loading and unloading. Flexible and efficient automation solutions are possible with a robot or linear system. The workpiece handling with robot technology is a quick and reliable step for increasing the capacity utilization and productivity of the MFP 50. The integration of further grinding machines, tool magazines and additional pro- cess steps such as cleaning and measuring are possible. MÄGERLE's expertise and experience with implemented automation solutions guarantee...

Open the catalog to page 8

Control Systems Customer Care Operational safety and user-friendliness in the center MÄGERLE surface and profile grinding machines should fulfill the customer's requirements for as long as possible, work costeffectively, function reliably and be available at all times. From “start up” through to “retrofit” – our Customer Care is there for you throughout the working life of your machine. 3 professional helplines and more than 11 service technicians are available in your area, wherever you are in the world. Commissioning Warranty extension We will provide you with fast, uncomplicated support....

Open the catalog to page 9

Machine Layout Technical data MFP 50 X-axis - longitudinal stroke Travel speed Y-axis - vertical stroke MFP 50 machine configuration legend MFP 50 working area Quick-change spindle for machining tools Interface to coolant processing system Cooling system for spindle drives Automatic coolant nozzles Hydrostatic/Hydraulic unit Overhead dresser Centralized lubricating system NC indexing head 2/3 axes Electrical cabinet Dressing device (optional) Mist extractor (interface) Automatic door drive Tool change magazine for machining tools Safety splash guard cabine Travel speed Z-axis - transverse...

Open the catalog to page 10All MÄGERLE AG Maschinenfabrik catalogs and technical brochures

-

MFP 30

16 Pages

-

MFP51

11 Pages

-

Product program

32 Pages

-

MAEG UEBERSICHT

32 Pages

-

PROFIMAT_MC_RT

9 Pages

-

PROFIMAT MT

9 Pages

-

UNITED GRINDING Group

35 Pages

-

MFP50

11 Pages

-

KRONOS

12 Pages

Archived catalogs

-

MÄGERLE GRINDING SYSTEMS_2019

36 Pages

-

MFP 100_2013

9 Pages

-

MÄGERLE GRindinG SyStEMS_2013

17 Pages

-

MFP 100

2 Pages