Catalog excerpts

A member of the UNITED GRINDING Group MFP 30 Compact solution for high productivity Key Data Top performance in a compact space Tool diversity and process flexibility Long service life with hydrostatics Swiss precision

Open the catalog to page 1

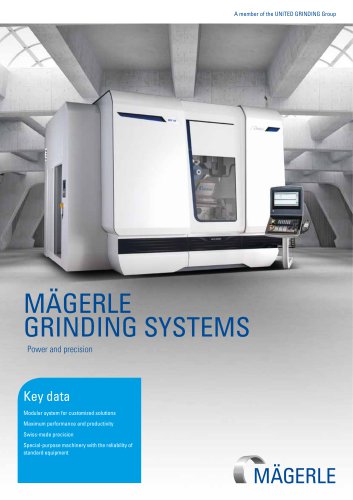

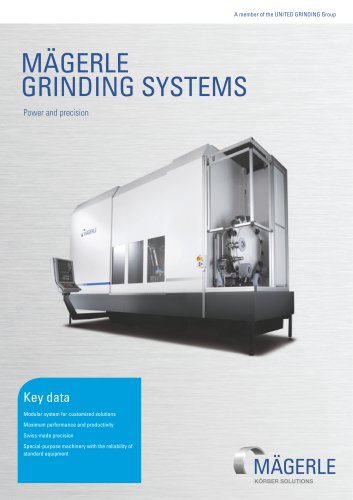

Mägerle AG Maschinenfabrik Precision, quality and flexibility are key attributes of the products manufactured by Mägerle AG Maschinenfabrik. A technology leader for highperformance surface and profile grinding systems, the company founded in 1929 primarily specializes in customized solutions. At the heart of the international success of our high-quality Swiss machinery is the unique design principle of the MÄGERLE modular system. Thanks to state-of-the-art technology, MÄGERLE can offer customers from many branches of industry reliable grinding centers. The high machining precision of the...

Open the catalog to page 2

MFP 30 Compact design · Automatic tool changer · Flexible machining options · Highest grinding and cooling capacity · Powerful drive for high speeds · Table dressing device with wide profile roll · Hydrostatic guideways · Maintenance-fr

Open the catalog to page 3

Pre-programmed grinding and dressing cycles User-specific programmable interface Intuitive operation Focus on work and production safety The compact MFP 30 5-axis grinding center from MÄGERLE is ideally suited for grinding complex geometries, particularly those of blades and vanes or heat shields for aviation turbines. The workpieces to be machined are ergonomically loaded into the work area directly from the front. Heavy workpieces with a clamping fixture can be loaded from the top using a crane. The compact and space-saving design allows optimal use of the available production area and...

Open the catalog to page 5

Machine Configuration MFP 30 machine concept ❹ ❶ Tool magazine ❷ NC indexing head ❸ Table dresser ❹ 2-axis NC coolant nozzle

Open the catalog to page 6

High performance and high torque Spindle capacity S6 at 40% duty cycle The direct drive motor for the grinding spindle enables high performances The high speeds of up to 12,000 rpm offer optimal conditions for CBN and torques across the entire speed range. This leads to outstanding re- grinding processes and milling operations, which significantly increases the machining clearance for complex workpieces. sults in terms of removal rates. Large grinding wheel dimensions 60 mm The powerful drive is designed for wide grinding wheels up to 60 mm. Operations can thus be combined with wide...

Open the catalog to page 7

Automatic Tool Changer Flexible loading options The tool changer includes 12 or 24 positions. It can be equipped with capability, which supports a flexible machining platform for complex workdifferent grinding wheels according to the process requirements. The grin- pieces. In addition, the magazine can be loaded with a measuring probe ding process can be supplemented with the machine's drilling and milling which allows for dimensioning or workpiece position checks.

Open the catalog to page 8

Hydrostatic System and Powerful Drives Table dressing for a multitude of profiles The large table dressing device enables the mounting of wide diamond rolls The two bearings and the servo motor drive enable reliable dressing across with a multitude of machining profiles for different workpieces and makes a the entire speed range. significant contribution to minimizing changeover times. Wear-free guide concept The unique design principle of MÄGERLE machining centers forms the basis for the overall machine quality. The vertical axis is supported by hydrostatic wrap-around guideways on a thin...

Open the catalog to page 9

Cooling Intelligence Optimal grinding and machining results The NC controls of the MÄGERLE grinding centers enable precise positi- spindle. Labyrinth seals with a sealing air arrangement protect all bearings oning of the coolant supply, taking into account the respective grinding in the machining area from impurities and contribute to the long working wheel geometry. Nozzles are available on the grinding support for milling/ life of the overall system. drilling tools, and a coolant supply can be optionally provided through the Grinding wheel cleaning Integrated grinding wheel cleaning...

Open the catalog to page 10

Coolant Cleaning Units The optimal solution for every application Endless belt with brush-of device Filter cake Inlet box Vacuum pump Filtering phase Filter cake Belt drive Blow-off device Drying area Brush-of device Scraper Reverse flushing device Endless belt Filter fleece with take-up unit Sludge container Filter cake Delivery pump Scraper worm Filter fleece Sludge tank Clean Tank MÄGERLE considers the grinding process as a system of different components and thus creates the necessary conditions for a high cost effectiveness. The system concept for coolant supply and cleaning is of central...

Open the catalog to page 11

Control Systems Operational safety and user-friendliness The grinding center is operated by means of the SIEMENS Sinumerik 840D Solution Line control unit. This system fulfills all industrial requirements in terms of safety and performance. Individually visualized and pre-programmed grinding and dressing cycles are available for efficient and multiple measuring programs are displayed workpiece programming. 3D grinding and auxi- on the touch screen in a clear and user-friendly liary cycles can be programmed for milling and manner. drilling operations in 5-axis machining. Additional tasks...

Open the catalog to page 12

Customer Care Start up MÄGERLE surface and profile grinding machines should fulfill the customer's requirements for as long as possible, work cost-effectively and function reliably. From “start up” through to “retrofit” – our Customer Care is there for you throughout the working life of your machine. Three professional helplines and trained service technicians are available in your area, wherever you are in the world. Commissioning Warranty extension We will provide you with fast, uncomplicated support. We will help to increase your productivity. We work professionally, reliably and...

Open the catalog to page 13

Layout MFP 30 Machine configuration Working area ❷ Quick-change spindle for machining tools ❸ Automatic coolant nozzles ❹ NC indexing head 2/3 axes ❺ Dressing device ❻ Gripper ❼ Tool change magazine ❽ Interface to coolant processing system ❾ Hydrostatic/Hydraulic unit ❿ Centralized lubricating system ⓫ Electrical cabinet ⓬ Mist extractor (interface) ⓭ Automatic door drive ⓮ Safety splash guard cabin ⓯ Sinumerik 840D contro

Open the catalog to page 14All MÄGERLE AG Maschinenfabrik catalogs and technical brochures

-

MFP 50

11 Pages

-

MFP51

11 Pages

-

Product program

32 Pages

-

MAEG UEBERSICHT

32 Pages

-

PROFIMAT_MC_RT

9 Pages

-

PROFIMAT MT

9 Pages

-

UNITED GRINDING Group

35 Pages

-

MFP50

11 Pages

-

KRONOS

12 Pages

Archived catalogs

-

MÄGERLE GRINDING SYSTEMS_2019

36 Pages

-

MFP 100_2013

9 Pages

-

MÄGERLE GRindinG SyStEMS_2013

17 Pages

-

MFP 100

2 Pages