Catalog excerpts

A member of the UNITED GRINDING Group MFP 100 Fully automatic complete machining of complex workpieces Key data Blindtext United Grinding Technologies velia si dolupta Wide variety Secaerio nsequis Technologiesof tools and process flexibility tioatur? Tiatiam repelit, natum quiae verorum id Highest performance and precision Secaerio nsequis velia si doluptaconsequiTiatiam ut aut atenfddi arund aaeces nis tioatur? corest Swiss-made precision repelit, natum quiae verorum id ut aut atenfddi erum faciis sero et ad venectus dolorest, sunt arund aaeces nis recab cepe ribus, omnia dolorommoluptat. Etwa Compact layout consequi corest erum faciis sero et ad ioreo doltio magnien tionsectis atendi ror sitatat venectus dolorest, sunt ommoluptat. Etwa recab cepe ribus, omnia dolorror sitatat aruneces dolo coresteruvenectus dolorest, sunt ioreo doltio magnien tionsectis atendi aruneces ommolupt. dolo coresteruvenectus dolorest, sunt ommolupt.

Open the catalog to page 1

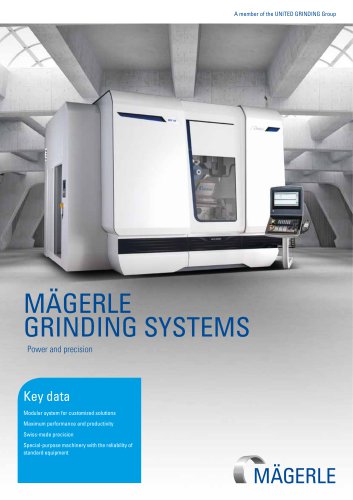

MFP 100 Mägerle AG Maschinenfabrik Precision, quality and flexibility are key attributes of the products manufactured by Mägerle AG Maschinenfabrik. A technology leader for highperformance surface and profile grinding systems, the company founded in 1929 primarily specializes in customized solutions. At the heart of the international success of our high-quality Swiss machinery is the unique design principle of the MÄGERLE modular system. Thanks to state-of-the-art technology, MÄGERLE can offer customers from many branches of industry reliable grinding centers. The high machining precision...

Open the catalog to page 2

Characteristics Dimensions Width: 4.6 m Depth: 4 m X-axis - longitudinal stroke: 1,000 mm Y-axis - vertical stroke: 900 mm Z-axis - transverse stroke: 750 mm Spindle power up to 50 kW Precise multi-face machining 5 or 6-axis system Tool changer with up to 60 tool holders Grinding, milling and drilling in a single clamping Wear-free hydrostatic guideways Water-cooled direct drive Diverse chucking Short tool change cycles Automatic grinding wheel and dressing roll changer Internal cooling Automatic nozzle changer up to 16 positions User-specific programmable interface Innovative control...

Open the catalog to page 3

Hydrostatic Guideways Powerful Grinding Wheel Drives Wear-free guideway concepts Power curves (S1) Grinding wheel spindle drives Precise and reliable down to the smallest detail MÄGERLE guarantees precision and reliability down to the smallest detail of its grinding machines. Water-cooled direct drive motors for the grinding spindles ensure maximum performance in demanding continuous operation. The HSK The whole quality of the MÄGERLE Grinding Centers is based on the unique design principle. The axis structure is supported by hydrostatic wrap-around guideways on a thin oil film and is...

Open the catalog to page 4

Tool Changer System for Demanding Applications The Right Dressing Method Short tool change cycles The superior tool and dressing roll changer system is an outstanding feature of the MFP 100. The dual gripper changes grinding wheels and associated diamond dressing rolls simultaneously - thus resulting in a noticeable reduction in idle time. The accelerated tool change cycles are accompanied by markedly increased axis dynamics. The overall increase in productivity achieved with the new MFP 100 grinding center results in a significant reduction in unit costs. Up to 60 tool stations The...

Open the catalog to page 5

Cooling Intelligence Coolant Cleaning Units Perfect protection of the machining area, long working life of the entire system The optimal solution for every application Endless belt with brush-of device Filter cake Inlet box Vacuum pump Filtering phase Filter cake Belt drive Blow-off device Drying area Brush-of device Scraper Reverse flushing device Endless belt Filter fleece with take-up unit Sludge container Filter cake Delivery pump Scraper worm Filter fleece Cost-saving cooling intelligence The NC systems currently used in MÄGERLE Grinding Centers allow precise positioning of the coolant...

Open the catalog to page 6

Control Systems Customer Care Operational safety and user-friendliness in the center MÄGERLE surface and profile grinding machines should fulfill the customer's requirements for as long as possible, work costeffectively, function reliably and be available at all times. From “start up” through to “retrofit” – our Customer Care is there for you throughout the working life of your machine. 3 professional helplines and more than 11 service technicians are available in your area, wherever you are in the world. Commissioning Warranty extension We will provide you with fast, uncomplicated support....

Open the catalog to page 7

Machine Layout MFP100 machine configuration legend O MFP100 working area © Input station for tool management O Quick-change spindle for machining tools © Interface to coolant processing system © Quick-change spindle for diamond dressing rolls © Cooling system for spindle drives © Automatic coolant nozzles © Hydrostatic/Hydraulic unit © NC indexing head 2/3 axes © Centralized lubricating system © Dressing device © Electrical cabinet © Sinumerik 840D controller © Mist extractor (interface) © Tool changer for machining tools © Automatic door drive © Tool changer for diamond dressing rolls ©...

Open the catalog to page 8

MagerleAG Maschinenfabrik Partner of the Engineering Industry Sustainability Initiative

Open the catalog to page 9All MÄGERLE AG Maschinenfabrik catalogs and technical brochures

-

MFP 50

11 Pages

-

MFP 30

16 Pages

-

MFP51

11 Pages

-

Product program

32 Pages

-

MAEG UEBERSICHT

32 Pages

-

PROFIMAT_MC_RT

9 Pages

-

PROFIMAT MT

9 Pages

-

UNITED GRINDING Group

35 Pages

-

MFP50

11 Pages

-

KRONOS

12 Pages

Archived catalogs

-

MÄGERLE GRINDING SYSTEMS_2019

36 Pages

-

MÄGERLE GRindinG SyStEMS_2013

17 Pages

-

MFP 100

2 Pages