Catalog excerpts

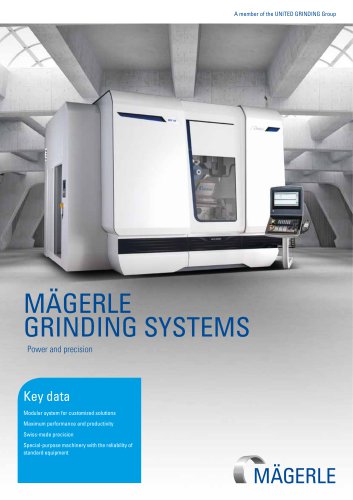

A member of the UNITED GRINDING Group MAGERLE GRINDING SYSTEMS Power and precisionKey data m MAGERLE Modular system for customized solutions Maximum performance and productivity Swiss-made precision Special-purpose machinery with the reliability of standard equipment

Open the catalog to page 1

Mägerle AG Maschinenfabrik Precision, quality and flexibility are key attributes of the products manufactured by Mägerle AG Maschinenfabrik. A technology leader for highperformance surface and profile grinding systems, the company founded in 1929 primarily specializes in customized solutions. At the heart of the international success of our high-quality Swiss machinery is the unique design principle of the MÄGERLE modular system. Thanks to state-of-the-art technology, MÄGERLE can offer customers from many branches of industry reliable grinding centers. The high machining precision of the...

Open the catalog to page 2

MÄGERLE GRINDING SYSTEMS MÄGERLE GRINDING SYSTEMS Established modular system · Hydrostatic guideways · Maximum grinding and cooling performance · Process expertise for high process reliability · System integration experti

Open the catalog to page 3

MÄGERLE GRINDING SYSTEMS Power • Precision • Reliability MÄGERLE Modular System Frictionless motion, even under extreme loads The unique design principle of the MÄGERLE grinding centers forms the basis of the machines’ high quality and reliability. Welded box-type steel construction designs, premium materials and components, and powerful drives guarantee the thermal stability of the systems and extreme machining precision. MÄGERLE set an important milestone with the invention of the fully enclosed hydrostatic guideway system. This ground-breaking design principle still distinguishes...

Open the catalog to page 4

MÄGERLE GRINDING SYSTEMS Demanding tasks With their equally high removal capacity and machining precision, MÄGERLE’s grinding centers are recognized on the market as top-class machines. They demonstrate their performances and versatility daily in demanding applications in the turbine industry, the automotive and aircraft industry, the hydraulics industry and the energy sector, as well as machine tools and toolmaking. All industries that make the highest demands in respect of mechanical, ergonomic and operational qualities. Swiss precision In 2002 MÄGERLE moved into the new building in...

Open the catalog to page 5

MÄGERLE GRINDING SYSTEMS Intelligent Modular System Using standard components to create individual solutions First class material, high-quality workmanship The surface and profile grinding machines of MÄGERLE are used especially in applications where quality and reliability are of prime importance. To meet these requirements, the Swiss specialists only use first class materials. Precision-ground, hand-scraped sliding surfaces and seatings combined with high quality ball-type linear drives ensure excellent grinding results. Modular system for individually designed high-quality products...

Open the catalog to page 6

MÄGERLE GRINDING SYSTEMS Modular System MÄGERLE Grinding Center MGC MGC with stationary console MGC with swivelling table MGC with rotary table and horizontal spindle MGC with rotary table and vertical spindle

Open the catalog to page 7

MÄGERLE GRINDING SYSTEMS Hydrostatic Guideways Wear-free guideway concepts The whole quality of the MÄGERLE Grinding Centers is based on the unique design principle. The axis structure is supported by hydrostatic wrap-around guideways on a thin oil film and is completely separated from the machine bed. As a result MÄGERLE grinding machines can withstand high loads without signs of wear – even in long-term use. The oil film has a vibration-damping effect and guarantees high-precision machining of simple or complex workpiece

Open the catalog to page 8

MÄGERLE GRINDING SYSTEMS Powerful Grinding Wheel Drives Power curves (S1) Grinding wheel spindle drives – horizontal 115 kW (S1) Grinding wheel spindle drives – vertical Precise and reliable down to the smallest detail MÄGERLE guarantees precision and reliability down to the smallest detail of its grinding machines. Water-cooled direct drive motors for the grinding spindles ensure maximum performance in demanding continuous operation. An optional balancing system dynamically balances unequal forces in the rotating grinding wheel. Front-runner in grinding power Powerful motors drive the...

Open the catalog to page 9

MÄGERLE GRINDING SYSTEMS Cooling Intelligence and Correct Dressing Methods Perfect protection of the machining area, long working life of the entire system Cost-saving cooling intelligence The NC systems currently used in MÄGERLE grinding centers allow precise positioning of the coolant supply together with the respective grinding wheel geometry over 2 NC axes. An optional profile adjustment enables precise application of the coolant to the workpiece zones for machining. Minimal coolant amounts thus provide maximum cooling capacity. Labyrinth seals with a sealing air arrangement protect all...

Open the catalog to page 10

MÄGERLE GRINDING SYSTEMS The right dressing method The dressing of the grinding wheels is a crucial factor for the efficiency of the grinding process. With overhead and table dressing devices, MÄGERLE provides professional solutions for the various requirements of this process step. The potential of the overhead principle is developed in continuous dressing (CD) and inprocess dressing (IPD). Table dressing devices are used for fixed or rotating dressing tools, where the rotating principle produces optimal results in full form dressing, cushing or CNC dressing. MÄGERLE uses servo motors for...

Open the catalog to page 11

MÄGERLE GRINDING SYSTEMS MFP 30 Compact solution for high productivity The compact MFP 30 5-axis grinding center from MÄGERLE is ideally suited for grinding complex geometries, particularly those of blades and vanes or heat shields for aviation turbines. The workpieces to be machined are ergonomically loaded into the work area directly from the front. Heavy workpieces with a clamping fixture can be loaded from the top using a crane. The compact and space-saving design allows optimal use of the available production area and enables an effective production flow. The powerful drive of the...

Open the catalog to page 12All MÄGERLE AG Maschinenfabrik catalogs and technical brochures

-

MFP 50

11 Pages

-

MFP 30

16 Pages

-

MFP51

11 Pages

-

Product program

32 Pages

-

MAEG UEBERSICHT

32 Pages

-

PROFIMAT_MC_RT

9 Pages

-

PROFIMAT MT

9 Pages

-

UNITED GRINDING Group

35 Pages

-

MFP50

11 Pages

-

KRONOS

12 Pages

Archived catalogs

-

MFP 100_2013

9 Pages

-

MÄGERLE GRindinG SyStEMS_2013

17 Pages

-

MFP 100

2 Pages