Catalog excerpts

A member of the United Grinding Group KRONOS Centerless external cylindrical grinding Key data The KRONOS series is synonymous with centerless external cylindrical grinding machines in the premium range with the German seal of quality. One grinding principle, three sizes – this impressive machine system delivers outstanding precision and the highest productivity. The range of applications extends from small needles to pump pistons and heavy shafts.

Open the catalog to page 1

Schaudt Mikrosa GmbH Schaudt Mikrosa GmbH is synonymous worldwide for cutting-edge technology in cylindrical, noncircular and universal grinding between centers, as well as in centerless external cylindrical grinding. Since 2009, the company combines the two long-established brands SCHAUDT and MIKROSA in a modern factory in Leipzig. SCHAUDT is the brand for the automotive industry and its suppliers. It offers sophisticated technological solutions for cylindrical, noncircular and eccentric grinding. Our highly experienced experts also have unparalleled expertise in the high-precision...

Open the catalog to page 2

KROnos Highest precision combined with maximum productivity · Broad technology spectrum · Tailor-made grinding solutions · Special software for centerless grinding · Broad range of applications

Open the catalog to page 3

MIKROSA KRONOS Top quality in centerless cylindrical grinding Centerless grinding Technology spectrum One grinding principle, three sizes - the KRONOS series from MIKROSA offers centerless cylindrical grinding technology in the high-precision range. Centerless grinding is a special type of external cylindrical grinding, which is primarily used in the series and mass production of cylindrical components. Two different process variants are available: throughfeed grinding and infeed grinding. Thanks to the linear workpiece support on the work rest and the regulating wheel, no deflection...

Open the catalog to page 4

MIKROSA KRONOS Applications The application range of the KRONOS series is very broad: • High-precision small components for injection technology • Shaft-type components for transmissions and motors • Rings and rolling elements • Special materials such as ceramic • Bars and other long, slender workpieces • Small components for medical technology

Open the catalog to page 5

MIKROSA KRONOS Machine expertise on all levels KRONOS S 125 Centerless grinding machine for cost-effective precision machining of highprecision, small workpieces | CBN-capable Technical data Workpiece diameter Max. workpiece length for infeed grinding Grinding wheel Ø Driving power Peripheral speed CBN peripheral speed Regulating wheel Ø Driving power Rpm range, continuously adjustable Dressing speed Typical grinding processes • Infeed grinding – straight or 15° angled • Infeed grinding in single or multiple production • Infeed grinding in several operations (simultaneous or consecutive) •...

Open the catalog to page 6

MIKROSA KRONOS Modular centerless grinding machine for optimal adaptation to the respective grinding task for small to medium workpieces | CBN-capable Technical data Workpiece diameter Max. workpiece length for infeed grinding Grinding wheel Ø Driving power Peripheral speed CBN peripheral speed Regulating wheel Ø Driving power Rpm range, continuously adjustable Dressing speed Typical grinding processes • Infeed grinding - straight • Infeed grinding in single or multiple production • Grinding of faces and diameters with grinding spindles on hydrodynamic bearings • Throughfeed grinding...

Open the catalog to page 7

MIKROSA KRONOS Machine expertise on all levels KRONOS L 550 Centerless grinding machine for cost-effective precision machining of medium to large workpieces Technical data Workpiece diameter Max. workpiece length for infeed grinding Grinding wheel Ø Driving power Peripheral speed Driving power Rpm range, continuously adjustable Dressing speed Typical grinding processes • Infeed grinding - straight • Infeed grinding in single or multiple production • Throughfeed grinding Centerless grinding machine for the precise mass production of large workpieces | CBN-capable | Special machine: KRONOS...

Open the catalog to page 8

MIKROSA KRONOS Customer Care MIKROSA centerless grinding machines should fulfill the customer's requirements for as long as possible, work costeffectively, function reliably and be available at all times. From “start up” through to “retrofit” – our Customer Care is there for you throughout the working life of your machine. 30 professional helplines and more than 60 service technicians are available in your area, wherever you are in the world. Commissioning Warranty extension We will provide you with fast, uncomplicated support. We will help to increase your productivity. We work...

Open the catalog to page 9

MIKROSA KRONOS Overview of technical data Platform KRONOS dual Workpiece diameter, min. Workpiece diameter, max. Workpiece length, max. infeed grinding Grinding range Grinding wheel Diameter, max. CBN peripheral speed (option) Driving power Rpm range, continuously adjustable Dressing speed Driving power Installation area (foundation) Overall area (incl.control cabinet) Regulating wheel Grinding wheel drive Peripheral speed Peripheral speed Regulating wheel drive Machine weight SIEMENS SINUMERIK 840D sl control system

Open the catalog to page 10

MIKROSA KRONOS

Open the catalog to page 11

KORBER SOLUTIONS Schaudt Mikrosa GmbH BLU© COMPETENCE Partner of the Engineering Industry Sustainability Initiative

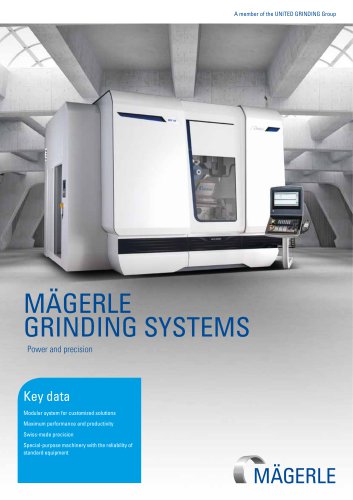

Open the catalog to page 12All MÄGERLE AG Maschinenfabrik catalogs and technical brochures

-

MFP 50

11 Pages

-

MFP 30

16 Pages

-

MFP51

11 Pages

-

Product program

32 Pages

-

MAEG UEBERSICHT

32 Pages

-

PROFIMAT_MC_RT

9 Pages

-

PROFIMAT MT

9 Pages

-

UNITED GRINDING Group

35 Pages

-

MFP50

11 Pages

Archived catalogs

-

MÄGERLE GRINDING SYSTEMS_2019

36 Pages

-

MFP 100_2013

9 Pages

-

MÄGERLE GRindinG SyStEMS_2013

17 Pages

-

MFP 100

2 Pages