Catalog excerpts

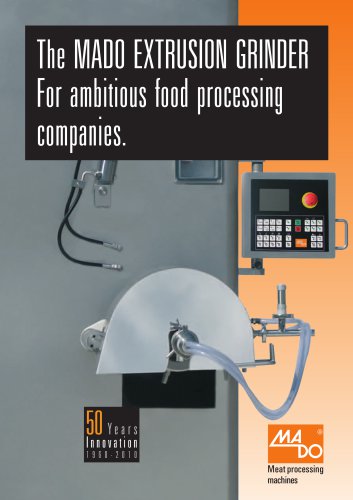

The MADO EXTRUSION GRINDER For ambitious food processing companies. Years Meat processing machines

Open the catalog to page 1

The MADO EXTRUSION GRINDER increases your profits. The new EXTRUSION GRINDER from MADO - specialist manufacturers of the most hygienic and cost-effective meat processing machines in the world save time and reduce investment capital by combining several processing stages into one. This revolutionary machine, designed for ambitious food processing companies, is the result of continuous dialogue with our customers. Eight variations in five different sizes are available. Patented, state-of-the-art technology, combined with first class materials and exceptional finishing, guarantees the best...

Open the catalog to page 2

A new era has dawned for the food processing industry. MADO’S EXTRUSION GRINDER is a revolutionary invention, reducing Hopper volume 130 litres three machine processes into one machine. Cutting, mixing and homoge- nization are all accomplished within this single unit, saving capital costs, reducing processing time and eliminating the transfer of product from one EXTRUSION GRINDER MMG 233 Hopper volume 500 litres machine to another. Imagine the elimination of transfer conveyors, the space and maintenance they require and the efficiency improvement that this machine offers. Another benefit of...

Open the catalog to page 3

EXTRUSION GRINDER – mixing, cutting and homogenizing in just one Machine. The MADO EXTRUSION GRINDER is the optimal solution for the modern food processing industry. Whether one processes cured, cooked, fresh sausage For even better production results and or other comminuted food, patented MADO technol- more specialised applications, the new ogy provides the most efficient production with the MADO EXTRUSION GRINDER can also high quality: grinding machines in the world. be supplied with an optional vacuum Products such as Hot Dogs, Wieners, cold cut emul- device. Mixing under vacuum im-...

Open the catalog to page 4

Higher efficiency Increased hygiene EXTRUSION GRINDER MMG 239 with Vacuum unit and “Duo-Separt” separator system Higher quality

Open the catalog to page 5

Everyone’s talking about the new EXTRUSION GRINDER from MADO. The speed of the mixing unit is variable and operates both forward and reverse. During the mixing process, the two feed augers run in reverse and push the material up the back wall of the hopper. This significantly enhances product mixing while reducing the blending time. The screws of the EXTRUSION GRINDER'S cutting assembly transport material in an exemplary gentle fashion. This ensures an excellent particle definition with the lowest possible temperature increase. E.g. when processing pork, Dt is only 0.5°C when using a 3 mm...

Open the catalog to page 6

3 to 7 piece cutting sets, individually configured for each product. Excellent product quality ● Integrating several processes within a single machine reduces microbial contamination of the raw material by up to 80%. ● Optimized homogenous mixing of all ingredients through patented cutting technology. ● The clear particle definition allows the processor to present an exceptional product. ● The double feed auger system prevents air pockets in the emulsion. Cost savings ● Mixing, grinding and emulsifying in one machine shorten processing times and reduces capital costs. This saves time and...

Open the catalog to page 7

Variants and equipment. “DuoSepart” bone elimination system The EXTRUSION GRINDER can be fitted with the patented “DuoSepart” elimination system upon request. This system allows you to separate bone, gristle and sinews effectively and efficiently. Processes which cause stress to raw materials, such as conventional separation systems, can also be eliminated, thus increasing you savings. The “DuoSepart” system consists of two separator units which work independently of each other. In the first stage, separation is carried out on the side. In the second stage it takes place centrally on the...

Open the catalog to page 8

Tool trolley Programmable control unit Feed screws with variable speed adjustment Mixing arm with variable speed adjustment Pump screws with variable speed All functional parts are removed from the EXTRUSION GRINDER and hung or placed on the tool trolley which comes as a standard accessory. This allows for easy, hygienic and spotless cleaning and disinfection of both the machine and the parts. With the tool trolley, space to be removed disassembly and storage of components is child’s play. This simplifies handling and keeps everything in good order. Cleaning platform Tool trolley

Open the catalog to page 9

Cleaning and maintenance made easy. Cleaning platform as standard To enable you to get the most out of your MADO EXTRUSION GRINDER, the machine comes complete with a robust cleaning platform. The platform is equipped with a safety interlock to provide the utmost in safety. All MADO EXTRUSION GRINDER drives are controlled by frequency converters and are thus completely variable in speed. Operators can also adjust the individual times and cycles of the mixing unit. All electrical elements are compactly sealed in the machine housing and are thus protected against moisture. A separate electric...

Open the catalog to page 10

Supplied with 130 litres – 2.200 litres hopper output volumes ranging from 3.600 to 12.000 kg/h Machine and equipment configurable Comes with vacuum or gas injection device upon request for essembly of feeding worms Several different mixing paddle designs available Variable mixing time and mixing speed, as well as variable feed and cutting PLC controler and touch panel as standard design without vacuum for essembly of feeding worms Can be used in all kinds of meat and food processing Current type Nominal current Motor capacity Fuse protection Cutting assembly Hopper volume

Open the catalog to page 11

Special machines for modern meat processing. Meat grinders Bowl choppers Band saws Knife sharpeners Mixers Portioning systems Industrial machines MADO machines comply with the EC Machine Norms. They are marked with the CE sign. MADO is certified according to DIN ISO 900@. Special voltages on enquiry. Technical changes made during the course of further development are reserved. Meat processing machines MADO special machines for modern meat processing at qualified specialists.

Open the catalog to page 12All MADO Maschinenfabrik Dornhan catalogs and technical brochures

-

MSM 767 VA SUPRA Cutter 130

6 Pages

-

MSM 767 SL SUPRA Cutter 130

6 Pages

-

MSM 764 M SUPRA 50 M Cutter

4 Pages