Website:

Macro Engineering & Technology Inc.

Website:

Macro Engineering & Technology Inc.

Catalog excerpts

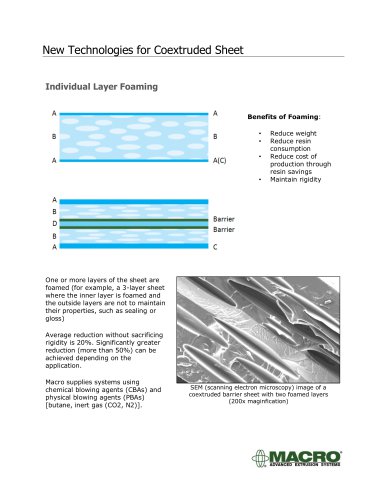

New Technologies for Coextruded Sheet Individual Layer Foaming Benefits of Foaming: • • • Reduce weight Reduce resin consumption Reduce cost of production through resin savings Maintain rigidity One or more layers of the sheet are foamed (for example, a 3-layer sheet where the inner layer is foamed and the outside layers are not to maintain their properties, such as sealing or gloss) Average reduction without sacrificing rigidity is 20%. Significantly greater reduction (more than 50%) can be achieved depending on the application. Macro supplies systems using chemical blowing agents (CBAs) and physical blowing agents (PBAs) [butane, inert gas (CO2, N2)]. SEM (scanning electron microscopy) image of a coextruded barrier sheet with two foamed layers (200x maginfica

Open the catalog to page 1

Benefits of Microlayers: • Increased strength • Improved thermoformability • Enhanced barrier properties Two additional extruders can be used to deliver two layers of material to a special feedblock that splits the flow into 20+ very thin layers. This creates alternating layers that can be positioned in the core of the structure. Barrier properties can be enhanced (such as alternating PA and EVOH microlayers) Mechanical properties can be improved (for example, alternating different PP or PS). Material can also be drawn deeper and thermoforms better in corners. This translates to making...

Open the catalog to page 2All Macro Engineering & Technology Inc. catalogs and technical brochures

-

Barrier Cast Film Lines

2 Pages

-

CPP Film Lines

2 Pages

-

Sheet Extrusion Technology

2 Pages

-

PS Foam Extrusion Line

2 Pages

-

DIO Air Rings

2 Pages

-

Blown Prestretch Film Lines

2 Pages

-

Barrier Biax Film Lines

2 Pages

-

Multilayer Blown Film Lines

2 Pages