Catalog excerpts

Bearing Components © 2015 Luoyang Bearing Corp. (Group) All Rights Reserved

Open the catalog to page 1

GENERAL INFORMATION • Founded in 1954 • Headquarters in Luoyang, Henan, China • Facility Size: 1,667,000 square metres • Employment: 11,000 total 2,500 Technical Personal • Annual Output: 120 Million bearings in 10 Categories • Sales in more than 70 countries © 2015 Luoyang Bearing Corp. (Group) All Right

Open the catalog to page 2

QALITY ASSURANCE • • • • ISO 9001 Certified ISO 14001 Certified ISO/TS 16949 AS9100 © 2015 Luoyang Bearing Corp. (Group) All Rights Re

Open the catalog to page 3

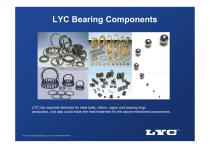

LYC has separate factories for steel balls, rollers, cages and bearing rings production, and also could make the heat treatment for the above mentioned components. © 2015 Luoyang Bearing Corp. (Group) All Rights Reserved

Open the catalog to page 4

LYC Bearing Components Bearing Rings LYC Turning Factory mainly produces 9 categories of bearing rings such as radial ball bearing rings, taper roller bearing rings, cylindrical roller bearing rings etc. Its annual production capacity of bearing rings is 40 million pieces and rollers are 4 million. Steel Balls LYC Steel Ball Manufacturing Factory can produce many kind of balls and stainless steel balls ranged from 3.175mm to 152mm with accuracy grade from G5 to G100. The vibration value of single ball from Z1 to Z5. The balls are suitable to be applied in various industries of wind power,...

Open the catalog to page 5

Inspection instruments: 20 sets Capacity: 13.8 Milliion pcs for Turning Parts, and 6 Million pcs of Rollers per year Product Range: Turning Ring with the OD from 30mm to 600mm; Roller with the diameter from 20mm to 146mm and heigh from 10mm to 191mm. © 2015 Luoyang Bearing Corp. (Group) All Rig

Open the catalog to page 6

Turning Machines Digital Controled Turning Machine Hydralic Type Copying Lathe Turning Machine for Rollers Turning Line for Rollers © 2015 Luoyang Bearing Corp. (Group) All Rights Reserved

Open the catalog to page 7

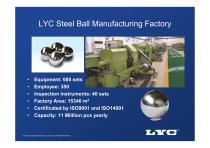

LYC Steel Ball Manufacturing Factory Equipment: 600 sets Employee: 350 Inspection instruments: 40 sets Factory Area: 15340 m2 Certificated by ISO9001 and ISO14001 Capacity: 11 Milliion pcs yearly © 2015 Luoyang Bearing Corp. (Group) All Right

Open the catalog to page 8

Production Range Ball Specification Steel brand

Open the catalog to page 9

Equipment and Instrument for Steel Balls Steel Ball Lapping Machine Production Line for Steel Balls © 2015 Luoyang Bearing Corp. (Group) All Rights Reserved Steel Ball Vibrometer S9502A

Open the catalog to page 10

Equipment and Instrument for Steel Balls Czech AVIKO Flaw Detecting Machine JQR AⅢ Automatic Steel Ball Ⅲ Appearance Detecting Instrument © 2015 Luoyang Bearing Corp. (Group) All Rights Reserved JCS-026 Steel Ball Roundness Test

Open the catalog to page 11

Technical Upgrading • Increased 10 sets of equipments before heat treatment • Increased 79 sets of equipments after treatment • Increased 8 sets of equipment for machine maintenance and transport • Increased 34 set of measuring instrument • Other testing instrument After technical upgrading,production capacity will reach 20 million pcs Yearly. The balls for precision bearing would meet G5 without abnormal sound. The balls for wind turbine bearing will be met with G10~G20. © 2015 Luoyang Bearing Corp. (Group) All Rights

Open the catalog to page 12

LYC Roller Manufacturing Factory • • • • • • • Equipment: 496 sets including 78 sets imported equipment Inspection instruments: 449 sets including 22 precision instruments Factory Area: 21640m2 Employee: 783 Medium and Senior Technician: 30 Certificated by ISO9001 and ISO14001 Roller Type & Range: Taper roller (Φ5~Φ60 mm), Cylindrical roller (Φ5 ~Φ60 mm), Spherical roller (Φ5 ~Φ60 mm), Needle roller (Φ3~Φ10 mm) © 2015 Luoyang Bearing Corp. (Group)

Open the catalog to page 13

Process Flow For Taper Roller Cold heading Soft grinding Super finishing Fine grinding and final grinding (XF-004) © 2015 Luoyang Bearing Corp. (Group) All Rights Reserved Heat treatment (Imported from Japan) Grind spherical fiducial surface Rough grinding

Open the catalog to page 14

Process Flow For Cylindrical Roller Pressing Soft grinding Rough grinding Heat treatment Quenching at protective atmosphere Super finishing Outer surface grinding © 2015 Luoyang Bearing Corp. (Group) All Rights Reserved Face grinding

Open the catalog to page 15

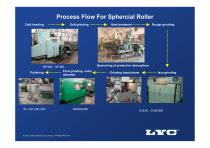

Process Flow For Sphercial Roller Cold heading Soft grinding NP450、NF460 Final grinding outer Polishing diameter © 2015 Luoyang Bearing Corp. (Group) All Rights Reserved Heat treatment Rough grinding Quenching at protective atmosphere Grinding basal plane face grinding

Open the catalog to page 16

Production Capacity Unit: Thousand Roller Type Over ⅡGrade Taper Roller Cylindrical Roller Spherical Roller Needle Roller © 2015 Luoyang Bearing Corp. (Group) All Rights Reserved

Open the catalog to page 17

Main testing Instruments Item Height meter Length Meter © 2015 Luoyang Bearing Corp. (Group) All Rights Reserved

Open the catalog to page 18

Equipment and Inspection Measuring Instrument Roundness Measuring Instrument Roughness Profiler Outer Diameter Grinder for Roller Superfinishing Machine for Imported from Germany Spherical Fiducial Surface ©2015 Luoyang Bearing Corp. (Group) All Rights Reserved

Open the catalog to page 19

Technical Upgrading • Since 2009,LYC has invested over 200million RMB(29million USD)on roller’s technological upgrading. • Among total investment, imported equipment value is over 60 Million RMB(8.8 Million USD) • All equipments are introduced from first-class roller equipment in the world or China • All equipment will be installed at second-half of 2010. • Manufacturing capacity on precision rollers (II grade rollers and I grade rollers) and the rollers for railway bearings will be enhanced extremely. © 2015 Luoyang Bearing Corp. (Group) All Right

Open the catalog to page 20

List of Imported Equipment • High precision spherical (Flat) Surface Grinding Machine for cylindrical roller (Manufacturer: SEIBU, Japan) • CNC supper finishing machine for cylindrical roller (Manufacturer: Supfina, Germany) • CNC Superfinishing machine for tapered roller (Manufacturer: Supfina, Germany) • CNC Superfinishing machine for cylindrical roller (Manufacturer: Supfina, Germany) • CNC Infeed Centerless Grinding Machine (Manufacturer: Mirosa, Germany) • CNC Through feed centerless grind machine (Manufacturer:Mirosa, Germany) • CNC Infeed Centerless grinding machine (Manufacturer:...

Open the catalog to page 21All LYC Bearing Corporation catalogs and technical brochures

-

Thrust Ball bearings

14 Pages

-

Taper Roller Bearings

25 Pages

-

Angular Contact Ball Bearings

25 Pages

-

LYC Slewing Bearings

85 Pages

-

LYC Needle Roller Bearings

13 Pages

-

LYC Spherical Roller Bearings

16 Pages

-

LYC Cylindrical Roller Bearings

34 Pages

-

LYC Deep groove ball bearings

26 Pages