Catalog excerpts

ALL-ROUND TALENT

Open the catalog to page 1

INDEX MISSION (IM)POSSIBLE 1 STUDER GRINDING SYSTEMS 2 SPANGLER BENEFITS FROM THE LSC WIRING SYSTEM 4 GIANT MACHINE IN RECORD TIME 5 ALL-ROUND TALENT WITH 240 WATT POWER 6 LUTZE TWITTERS AND POSTS 6 NEW MANAGING DIRECTOR AT LUTZE 6 Creating Value from Sustainability Many of our customers are recognised industry leaders and for a good reason. They are innovative companies that market products that fulfil far more than just their warranty requirements. This is precisely the point where we feel we are responsible for investing in the sustainability of our products and...

Open the catalog to page 2

Mission (im)possible Robert Fearnett, LÜTZE UK Reduce Costs and Create Added Value... Impossible or Not? Cost reductions and shorter lead times: probably the two most talked about issues for any supplier in the manufacturing industry. No one wants to stock large amounts of components and the extremely harsh competitive environment is squeezing prices tightly for all suppliers - including LÜTZE UK. Suppliers who want to stay one step ahead need to offer good value whilst helping customers reduce their overall costs. This is the approach that LÜTZE UK has taken with a number of its customers...

Open the catalog to page 3

Studer Grinding Systems with LÜTZE SUPERFLEX® Bernhard Frutiger, Fritz Studer AG, Thun, Switzerland and Patrick Büsser, LÜTZE AG, Siebnen, Switzerland Based in the picturesque surroundings of Thun in the Bernese Oberland region of Switzerland, Fritz Studer AG produces cylindrical grinding systems. The systems are used for a wide variety of applications and the company meets the sophisticated demands of industrial customers including the Swiss watch-making industry, automotive manufacturers, manufacturers of pumps, turbines and transmissions as well as metering equipment producers. Studer...

Open the catalog to page 4

- Rich Vinnece, LÜTZE USA Automation Solutions are on the move at LÜTZE‘s Michigan Distributor HH Barnum. Fall throughout Michigan, Northern Indiana and Northern Ohio. Generally the Tour stops at three to four OEMs and/or end users per day. The Tour always is manned by at least one Barnum Technical Support person, a Barnum Product Manager, the Barnum Account Representive responsible for the OEM/end user along with several supplier reprentatives who provide their high level of technical support as well. Not only can the end user learn about new products, but they are able to experience hands...

Open the catalog to page 5

SPANGLER Benefits from the LSC Wiring System - Tina Lambert, SPANGLER GMBH SPANGLER is the specialist for developing automation solutions for different sectors and industries based throughout the world. The medium-sized family company based in the town of Töging in the Altmühltal region of Bavaria currently employs 114 workers and has been a reliable partner of the international machine and plant engineering industry for the last 30 years. More than 50 % of the systems produced by SPANGLER are exported. Customers from a variety of industries including environmental technology, agriculture,...

Open the catalog to page 6

Giant Machine in Record Time Steffen Friedrich, LÜTZE Germany Rapid LÜTZE solutions for longest gear-forming spinning machine in the World After submitting a quotation, the machine tool manufacturer Leifeld emerged as the winner of an international invitation to tender to build the World's largest gear-forming spinning machine. The 30metre long giant weighing 200 tonnes had to be designed and constructed under enormous time pressure – with installation technology and cable assemblies from LÜTZE. This ultra-modern stretch-forming spinning machine was commissioned by a subsidiary of a large...

Open the catalog to page 7

•• LUTZE twitters and posts All-round Talent with 240 Watt Power • • New managing director at LUTZE LUTZE has extended its successful Compact Power Supply Unit family to include a primary 240 Watt voltage supply that can alternatively be used in 1,2 or 3-phase operation. A classic all-rounder for the control cabinet. Despite 240 Watts of power, the LUTZE engineers have squeezed all the technical features into an overall width oft ust 55 mm. High-performance wiring systems can still be integrated into the restricted space available in the control cabinet. LUTZE offers the new 240 watt power...

Open the catalog to page 8

Flexible, versatile and reliable The automation specialist LUTZE, Weinstadt, is introducing the highly flexible Ethernet bus cable Cat. 6 SUPERFLEX® for cable carrier applications. The life of an Ethernet cable used in a power cable carrier is "brutal". Rapid death of the cable is frequently pre-programmed. Its no wonder: Use in cable carriers is characterised by the highest mechanical loads in terms of bending and moving in tight radii, while long travel distances, high speeds and acceleration have frequently shortened the life of many such cables significantly. For this reason, LUTZE has...

Open the catalog to page 9

Excellent Frame Concept with LSC Raphael Rossi, LÜTZE France What started with a streamlined control cabinet solution progressed into a close partnership Every engineer's dream is to make machines and mobile equipment more compact. LÜTZE found a solution for a French mechanical engineering company – the start of a beautiful friendship. Arras Maxei is a mechanical engineering company based in the North of France. For over 60 years, the company has been a competent partner and supplier to manufacturers of transformers and electrical motors. Part of the company's work involves building mobile...

Open the catalog to page 10

Caution - Slippery When Wet! Andreas Schindler, LÜTZE Germany NOWE GmbH, a company of the "Faiveley Transport Group", delivers innovative and reliable sand scattering systems that are modular in construction and specially designed to customer requirements. LÜTZE components ensure a precise metering of sand quantities and guarantee safe operation even at low temperatures. wasting energy, it also causes excessive wear of the wheels or tracks. To create the required amount of friction, sand is applied into the wheel-track gap by compressed air. As part of a new tram project, LÜTZE components...

Open the catalog to page 11All LÜTZE catalogs and technical brochures

-

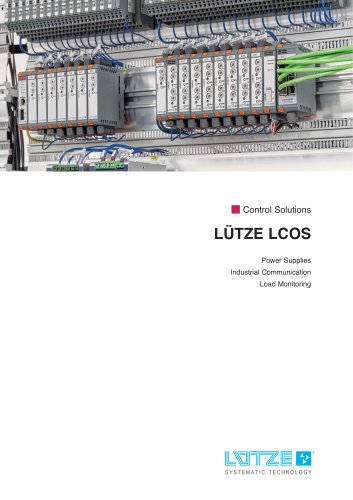

LÜTZE LCOS

73 Pages

-

Lutze Report 28

12 Pages

-

Lutze Report 31

8 Pages

-

Lutze Report 32

12 Pages

-

Lutze Report 33

9 Pages

-

Lutze Report 34

9 Pages

-

Lutzre REport 35

16 Pages

-

Lutze Report 36

12 Pages

-

Industrial Automation

9 Pages

-

LSC Wiring System

36 Pages

-

Safe connections

5 Pages

-

Industrial Power Supplies

132 Pages

-

LUTZE Converters

64 Pages

-

LOCC-Box-ED

2 Pages

-

LCIS

2 Pages

-

Lutze Connectivity Solutions

174 Pages

-

AirSTREAM

76 Pages

-

High flexing

56 Pages

-

Product overview

28 Pages

-

LUTZE-REPORT

17 Pages

-

LUTZE News Cable

12 Pages

-

Innovations SPS IPC Drives 2018

24 Pages

-

Ethernet Connectivity

60 Pages

-

Lighting element

3 Pages

-

Indicator-light board 3×3

2 Pages

-

LÜTZE LSC Wiring System

36 Pages

-

LSC AirSTREAM

33 Pages

-

Siemens 6FX

12 Pages

-

Automation Guide

12 Pages

-

Ethernet-connectivity

52 Pages

-

CablefixVario

4 Pages

Archived catalogs

-

Skyblue_2012

12 Pages

-

SkyBLUE_2011

7 Pages

-

LSC Wiring System

33 Pages

-

Lutze Fittings

16 Pages

-

Lutze USA Cable Selection Guide

32 Pages