Website:

LSP Industries, Inc.

Website:

LSP Industries, Inc.

Group: LSP Industries

Catalog excerpts

The PresSpray II, an airless spray lubricating system, is designed to deliver a predetermined amount of lubricant to the die area on each cycle of the press. The stamping industry demands versatility. PresSpray II delivers it.

Open the catalog to page 1

LSP INDUSTRIES INC. Presents The PresSpray II In 1964, when LSP first released the original PresSpray Lubricant Ejectors, we were at the forefront in introducing the Automatic spraying of lubricants to the stamping industry. Back then, presses were simple, the feeds slow and the lubricants primitive. Today the presses are high tech, the feeds faster, and the lubricants sophisticated. To keep up with these changes we have redesigned our equipment to incorporate the features necessary to compete in today's market. The PresSpray II The basic design of the PresSpray II is simple but functional:...

Open the catalog to page 2

THE PRESSPRAY II The Next Generation Of Die Lubrication Each PresSpray II Ejector controls an individual Nozzle, allowing you infinite adjustability over the spray pattern. By simply fine tuning the Regulator, Volume Control, and/or the Velocity Control it is possible to change the spray pattern of a nozzle without changing the nozzle itself. The PresSpray II is designed and constructed to handle all the jobs, from large heavy applications to those that require just a whisper of spray. No matter what your application, the PressSpray II will deliver. Air Inlet Tubing Filter/Regulator Oiler...

Open the catalog to page 3

These are free standing systems that are totally self contained and can be set up in minutes. Simply attach an air line and fill the reservoir with lubricant. Once this is done simply attach the nozzles to the Ejectors, put the actuator in place and bleed the system. The system is now operational and will work in unison with the press. The system is small enough to be moved from machine to machine, either by carrying or moving it about on the PortaPlatform but large enough for dedication to a single machine. The PresSpray II Mounted on a Reservoir The PresSpray II Mounted on a Four Gallon...

Open the catalog to page 4

PresSpray II (mounted on a bracket) Fed by a PowerPump from a Remote Reservoir The PresSpray II mounted on a bracket is a perfect choice for those jobs that need a dedicated lubricating system. A PowerPump is the preferred choice for supplying lubricant to the system. The PowerPump can be mounted on the bracket or on a central reservoir and then used to feed multiple systems at different locations. On large presses, we recommend mounting two smaller units on opposite sides of the press, fed by a single pump. This is more efficient than a large unit and gives better spray coverage. The...

Open the catalog to page 5

LSP Industries offers not one but four different methods of activating the PresSpray II. The system can be controlled with totally air operated actuators such as the Actuator Switch or the Air Timer. For those that demand more sophistication there is a solenoid operated actuator or the LSP Variable control package. For the unusual job it is possible to combine some actuators in combinations to produce unique results. Controllers and Solenoid Valve are supplied with 110 volt as standard. Alternate voltages are available. The Ultimate PresSpray Controller, offers three individual controls in...

Open the catalog to page 6

NOZZLE ASSEMBLIES For The PresSpray II Nozzles come in an assortment of spray patterns and each comes equipped with a Check Valve that prevents dripping of the lubricant after each actuation. Various accessories are available for enhancing the portability of the nozzle or permanently mounting the nozzle to a particular part of the die or press. Magnetic bases allow rapid repositioning of the complete nozzle assembly, the flexible hoses or the swivel brackets to simplify the delicate positioning of the nozzle tip itself. Here's How The Nozzle Assembly Works: Lubricant (from the reservoir) is...

Open the catalog to page 7

Selecting which Nozzle type to use for an application depends on three considerations: • The lubricant to be sprayed-water soluble, synthetic or straight oil? • The kind of spray coverage desired and which "Spray Pattern" will best provide it. •How the Nozzle is to be mounted (or positioned) and its spray directed. The options offered by LSP Industries in each of these areas are described below and on page 10. To order nozzles see page 6 for Catalog Numbers and descriptions. Know Which Nozzles to Use and How to Use Them. The Fan Spray nozzles are available in a diverse series allowing the...

Open the catalog to page 8

The PresSpray II was designed to handle a variety of jobs in the stamping department. Most dies can be lubricated by synchronizing the spray directly into the die, but for the unusual job it may mean lubricating prior to entering the die, making a special nozzle, or even building the nozzles into the die. Shown below are a few special applications to solve your lubrication problems. The Air Timer & Electronic Controls For faster applications we recommend the PresSpray II be cycled with either the P-908 Air Timer or the E-100 PresSpray Controller. These units dispense lubricant on programmed...

Open the catalog to page 9

Specifying a lubricating system the easy way! Each Ejector dispenses from .000 to .040 cu. in. per actuation and can spray lubricants with viscosities up to 2500 SUS's at 1000 F. Since these parameters are fixed you just decide which package best fits your needs. Shown below are the physical dimensions of the PresSpray II. PresSpray II Mounted on a Small Reservoirs Includes Filter/Regulator/Oiler. Order Actuator, Nozzles and Accessories Seperately.

Open the catalog to page 10All LSP Industries catalogs and technical brochures

-

PresSpray-II

16 Pages

-

Hammers

4 Pages

-

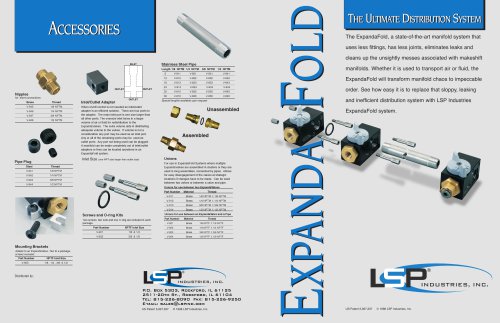

EXPANDAFOLD

4 Pages

-

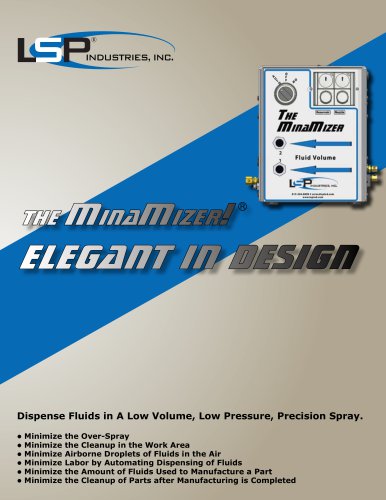

MinaMizer

5 Pages

-

Compuspray

4 Pages

-

PresSpray I

9 Pages

-

MeterMizer

16 Pages

-

MiniCoater

3 Pages

-

B-Coater

5 Pages

-

Hammers

4 Pages

-

Mist Coolant

5 Pages

-

FloaterCoater

7 Pages

-

BlastMatic

6 Pages

-

MaxaMizer

5 Pages