Website:

LSP Industries, Inc.

Website:

LSP Industries, Inc.

Group: LSP Industries

Catalog excerpts

No better airless spray design for die lubrication!

Open the catalog to page 1

PresSpray Models The PresSpray automatically dispenses a predetermined amount of lubrication in an instantaneous airless spray in unison with the cycle of the press. In an airless spray, the droplets are large and heavy and will not fog the work area. The PresSpray Ejector draws lubricant into the system and then forcefully ejects it out of the Spray Nozzles in a fine airless spray. Set the desire volume of lubricant needed and that volume will be dispensed on each cycle of the press. Dies lubricated automatically will run longer, cooler and faster. The operator does not have to worry about...

Open the catalog to page 2

Nozzle Assemblies The PresSpray Ejector is the HEART of the system. It dispenses lubricant out of the Nozzles with sufficient force to break the lubricant into a fine airless Spray pattern. Determining what options are needed depends on the number of nozzles needed, viscosity of the lubricant, method of actuating it and where the Reservoir is to be located. Actuators: The Actuators when tripped send a signal to the PresSpray to dispense fluid. Reference Page 10 and 11 for complete information on all of the Actuator. Mechanical Actuator Bracketed Modules Includes a PresSpray, FRO and a...

Open the catalog to page 3

PresSpray Modules Bracketed Module A Bracketed Module consists of a PresSpray Ejector and a group of components preassembled on a bracket in a single, compact module. For convenience, the PresSpray attaches to a Bracket that includes an Air Filter/ Regulator/Oiler. A two or four port Manifold (the MicroSpray does not have a Manifold) is included with the Module. By installing the Manifolds down stream this greatly makes for a cleaner installation. The Bracketed Module takes most of the work out of installation. The user has only to decide how to interface this system with the Spray Nozzles,...

Open the catalog to page 4

Creating Nozzle Distribution Systems The PresSpray offers a variety of ways to locate nozzles in a press to offer maximum spray coverage of the die or stock while allowing for the cleanest installation possible. Locate where the nozzles are to be positioned to determine if the distribution manifold is to be mounted on the PresSpray or down stream on the press. Nozzles for the PresSpray Systems A vast variety of Nozzles and Nozzle Accessories are available to individualize every PresSpray application. Choose the Nozzle of choice and Accessories to fit your particular application. P20X The...

Open the catalog to page 5

Mechanical and Electronic Options for Activating the System Three basic Actuators are available for cycling the PresSpray Ejector. The basic Actuators consist of a Mechanical Actuator that triggers when a moving part of the press moves a whisker. Another Actuator is a Solenoid Valve which receives a signal from a limit switch and then activates the PresSpray. A third Actuator is the LSP Air Timer that works on a predetermined time cycle unrelated to the cycle of the press. The LSP Industries Electronic Controller is specifically designed to control the operation of the PresSpray systems....

Open the catalog to page 6

Customize a PresSpray System Imagine the Different Installations Special Installations LSP Industries, Inc goes beyond its standard line. When called upon LSP Industries has modified standard products to meet customers requirements. Here we show but a few of the modifications made for our customers. The PresSpray Ejector can handle a full range of jobs based on its options setup. LSP Industries, Inc. manufactures a variety of actuators. The P901 Mechanical Actuator is a proven actuator that has been a standard for many years. Electronic actuators give smaller PresSprays the ability to do...

Open the catalog to page 7

Bracketed Modular Dimensions Modular PresSpray Manifold A B C D E F Controller Dimensions Model ABCDEFGHI Reservoir Dimensions Specifications P708-A Reservoir Modular Reservoir Modular Dimensions Modular PresSpray Gallons A B C D E F Reservoir Modular Dimensions Lubricant Outlet PresSpray Nozzles PresSpray Ejector Dimensions.

Open the catalog to page 8

P312-C 1-1/2 gallon Reservoir P315-C 5 gallon Reservoir Reservoirs include four feet of Outlet Tubing to connect to PresSpray Ejectors. A sight gage provides instant indication of fluid level and a lubricant filter prevents contaminants from entering the system. P-301 1 quart Reservoir for MicroSpray P-305 1 quart Reservoir with Magnetic Base Includes four feet of outlet tubing to connect to MicroSpray Units. Level Controls 100 Reservoir Size 100 Series Level Control Activates a light when the lubricant level is low. Can also be tied in to shut off a machine. Fluid Outlet Tubing Quick...

Open the catalog to page 9All LSP Industries catalogs and technical brochures

-

PresSpray-II

16 Pages

-

Hammers

4 Pages

-

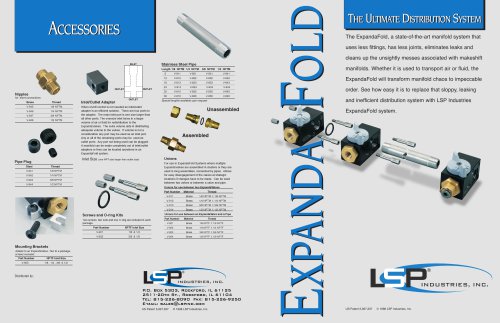

EXPANDAFOLD

4 Pages

-

MinaMizer

5 Pages

-

Compuspray

4 Pages

-

PresSpray II

10 Pages

-

MeterMizer

16 Pages

-

MiniCoater

3 Pages

-

B-Coater

5 Pages

-

Hammers

4 Pages

-

Mist Coolant

5 Pages

-

FloaterCoater

7 Pages

-

BlastMatic

6 Pages

-

MaxaMizer

5 Pages