Website:

Lovejoy

Website:

Lovejoy

Group: TIMKEN

Catalog excerpts

Specialty Products

Open the catalog to page 1

Specialty Products Safety Warning When using Lovejoy products, you must follow these instructions and take the following precautions. Failure to do so may cause the power transmission product to break and parts to be thrown with sufficient force to cause severe injury or death. Refer to this Lovejoy Catalog for proper selection, sizing, horsepower, torque range, and speed range of power transmission products, including elastomeric elements for couplings. Follow the installation instructions included with the product, and in the individual product catalogs for proper installation of power...

Open the catalog to page 2

Specialty Products

Open the catalog to page 3

Specialty Products Overview The patented Deltaflex series of couplings offer maximum misalignment capabilities with negligible reactionary load, for longer equipment life. This all-metal flex-link coupling requires no lubrication or other maintenance. Typical applications include: compressors, pumps, fans, positioning devices, indexing tables, mixers, papermill roll drives, drive line shafts, turbine drives, wind tunnels, cooling towers, and single bearing generator drives. The Saga series of couplings offer lower torsional stiffness than any other rubberin-compression coupling. There is no...

Open the catalog to page 4

Specialty Products Deltaflex Coupling Design The Deltaflex coupling is the real solution to installation, misalignment, and performance problems. Conventional couplings – even when carefully aligned to the manufacturer’s specifications – cannot match the low level of vibration, moment of inertia, and additional cushion for future misalignment of a visually aligned Deltaflex coupling. In addition, the Deltaflex coupling gives longer life to equipment shaft bearings. That means longer operating time and reduced maintenance cost. The Deltaflex can handle greater shaft misalignment without...

Open the catalog to page 5

Specialty Products Patented Design Concept*** The concept of the Deltaflex coupling and its misalignment capabilities can be illustrated best when compared to conventional coupling design (see Graphs C and D). Most conventional couplings’ torque and misalignment capabilities are dependent upon a single flexing member. Soft elastomers are limited by the compressive or tensile strengths of the material. Misalignment is a function and limitation of the material properties and method of connection to the hubs. As graphs A and B clearly illustrate, radial load placed on the shaft bearings of the...

Open the catalog to page 6

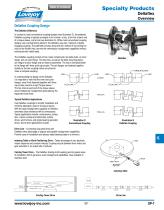

Lovejoy Coupling Solutions Specialty Products Deltaflex Overview Deltaflex Coupling Design The Deltaflex Difference In contrast to most conventional coupling designs (see illustration D), the patented Deltaflex coupling is typically arranged in this manner: a hub, a flex-link at each end of a torque sleeve, and a hub (see illustration E). While most conventional coupling designs use a central flexing element, the Deltaflex uses two, making it a double engaging coupling. The patented concept, along with the method of connecting the hubs to the flexible links, permits the tremendous...

Open the catalog to page 7

Specialty Products Deltaflex Types The unique design, misalignment capability and simple installation methods make Deltaflex easily adaptable to special applications. Contact Lovejoy Engineering for assistance. Type 1 Deltaflex Coupling Types JW This is the standard arrangement for most shaft to shaft applications. There are five basic coupling sizes in all types, each with a Standard and a High Torque (HT) Series. Both the Standard and the HT Series are dimensionally interchangeable. Shaft to Shaft – Hubs Mounted Internally This arrangement is similar to Type 1 in that all components are...

Open the catalog to page 8

Specialty Products Deltaflex Types equipment service factor (SFa): Using the A. riven D Application Service Factors Chart 1 (page SP-10) select the service factor which best corresponds to your application. If the application is not listed in Chart 1, use Chart 2. Step 5: Check limiting conditions. D. heck maximum speed. If operating speed exceeds 60% of listed C maximum speed, the coupling should be dynamically balanced. C. heck other dimensions such as the limits on shaft separation, C hub spacings, space required for the coupling, etc. Selection Examples Step 3: this case, the maximum...

Open the catalog to page 9

Specialty Products Application Service Factors Notes: n Typical Service Factors Electric Motor and Turbine Driven Equipment. n If people are transported, Lovejoy does not recommend and will not warranty the use of the coupling. Application Service Factors Selection Process Service Factors for Driven Equipment Load Classifications Note: n indicates: Torque load reversal can exist without reversing rotation and can be caused by overrunning the load with inertia or shifting of the load. * Consult Lovejoy Engineering.

Open the catalog to page 10

Lovejoy Coupling Solutions Specialty Products Deltaflex HP / Torque Ratings Performance Data Deltaflex HP and Torque Ratings Chart 3 Note: ■ 1 indicates: The HP ratings listed are for drives with a Service Factor of 1.0. Refer to Chart 1 (page SP-10) for Application Service Factors. Further, the ratings are based on prime movers such as electric motors or turbines. Note: ■ Internal Combustion Engines: Deltaflex couplings are not recommended for direct connection to internal combustion engine drives.

Open the catalog to page 11

Lovejoy Coupling Solutions Specialty Products Deltaflex Type 1 Dimensional Data Type 1 Shaft to Shaft - Hubs Mounted Internally This is the standard arrangement for most shaft to shaft applications. There are five basic coupling sizes in all types, each with a Standard and a High Torque (HT) Series. Both the Standard and the HT Series are dimensionally interchangeable. Type 1 features the standard inner and outer flanges and delta hubs, which are triangular in shape to accommodate the delta flex-link pattern. The standard flanges are stamped steel, while the flex links in all Deltaflex...

Open the catalog to page 12

Lovejoy Coupling Solutions Specialty Products Deltaflex Type 2 and 2A Dimensional Data Type 2 Shaft to Shaft - Hubs Mounted Externally This arrangement is similar to Type 1 in that all components are the same, except the delta hubs are mounted outside the flanges. An optional version of the Type 2 uses round hubs mounted externally on both ends or on one end to accommodate larger bore requirements. Type 2 is available as a stock option with stainless steel flanges and stainless steel round hubs. Delta style hubs are not available in stainless steel. Type 2A Shaft to Shaft - One Hub...

Open the catalog to page 13All Lovejoy catalogs and technical brochures

-

Torsional

42 Pages

-

HercuFlex Gear Couplings

28 Pages

-

Lovejoy Hydraulics

24 Pages

-

RunRight by Lovejoy Catalog

68 Pages

-

HercuFlex Couplings Catalog

28 Pages

-

QUICK FLEX® Couplings

56 Pages

-

Grid catalog

19 Pages

-

High Performance Gear Catalog

20 Pages

-

Jaw

28 Pages

-

4 BOLT DISC COUPLING

2 Pages

-

Disc

28 Pages

-

Universal Joints Catalog

12 Pages

-

Curved Jaw Couplings Catalog

22 Pages

-

Stainless Steel Jaw Catalog

2 Pages

-

Complete Lovejoy Catalog

522 Pages

-

HydraulicReservoir

24 Pages

-

LH COUPLINGS

2 Pages

-

Motion Control Catalog

22 Pages

-

Jaw In-Shear

8 Pages

-

4 Bolt Disc Catalog

2 Pages

-

Disc Catalog

28 Pages

-

Jaw Type Catalog

28 Pages

-

Lovejoy / Sier-Bath Gear Catalog

78 Pages

-

FARR Gear Catalog

7 Pages

-

Stainless Steel Jaw

2 Pages

-

Torsional catalog

42 Pages

-

Specialty catalog

28 Pages

-

Universal Joint catalog

12 Pages

-

BNZ Cooler Catalog

32 Pages

-

Pump/Motor Mount Catalog

24 Pages

-

Shaft Locking Devices catalog

24 Pages

-

Motion Control Couplings

22 Pages

-

Gear catalog

78 Pages

-

Curved Jaw catalog

22 Pages

-

Jaw In-Shear catalog

8 Pages

-

L-LOC Clamp Feature

1 Pages

Archived catalogs

-

RunRight Products Catalog

68 Pages

-

Full Line Catalog

56 Pages

-

S-Flex

22 Pages

-

Jaw Coupling

28 Pages

-

S-Flex catalog

22 Pages

-

FARR Rigid Couplings

6 Pages

-

Engineering Data

24 Pages