Catalog excerpts

IQ4 METAL DETECTION SYSTEMS

Open the catalog to page 1

Metal Detection Ever since LOMA SYSTEMS® was founded in 1969, the company has worked very closely with both food manufacturers and retailers to deliver advances in technology. As a result, LOMA® has an unrivalled level of experience and expertise, in the practice of effective metal detection within food industry production lines. Our latest introduction of the IQ4 series of Metal Detectors is the result bringing together the combined experience of LOMA, LOCK Inspection, CINTEX and BRAPENTA, and nearly 50 years of customer-back innovation. LOMA’s engineering teams have employed the Designed...

Open the catalog to page 2

Meet the New IQ4 Search Head Faster, Better Auto-Learn Standard across all of the IQ4 range, the big 7” touchscreen offers 33% more space than previous generation metal detectors Optimized mechanics and improved product screen help to deliver performance improvements over prior generation detectors With signficant improvements in signal processing, the new Auto-Learn rapidly delivers excellent detection sensitivities out of the box and provides more line uptime than ever before Engaging User Interface The newly designed interface provided across the entire range makes light work of setting,...

Open the catalog to page 3

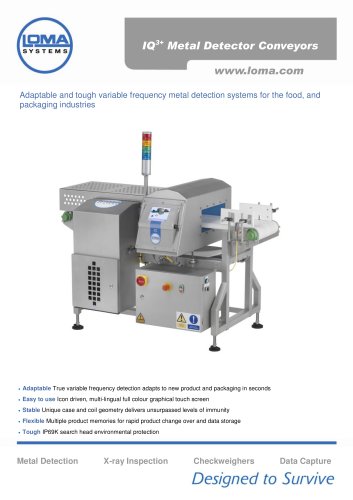

IQ4: Metal Detector Conveyors Combining the advanced functionality of the IQ4 Metal Detector Search Head with a conveyor to create a complete system compliant to food safety standards Full Retail Compliance Systems comply with strict international standards such as IFS, BRC, and FSMA; and can also be supplied with “Higher Level Compliance” functionality to meet the strictest of Retailer Codes of Practice Wide Product Application LOMA engineers deliver standard configurations and design complete bespoke systems to suit a wide variety of food product applications Capable Reject Options...

Open the catalog to page 4

IQ4: Pumped Products Introducing true Variable Frequency technology for pumped applications The IQ4 Pipeline metal detectors are built around LOMA's variable frequency technology that helps provide the best detection levels for different product conditions. Coupled with the new Auto-Learn, it makes set-up of the system for a product, quick and easy. IQ4 Pipeline Pipeline system is designed for use in pumped meat applications or nonmeat applications such as with liquids, soups or sauces • 7” Color Touchscreen Rejects to Suit Product Application With over 20 years of research...

Open the catalog to page 5

IQ4: Gravity Fed Products Introducing LOMA’s Variable Frequency Technology into Gravity Fall applications that helps to deliver great detection sensitivities with differing product conditions IQ4 Vertical Fall Gravity fed system for inspecting powders or granules • Can be installed at the beginning of the production line to inspect materials in bulk powder or granule form Variable Frequency Technology Sealed to IP66 for wash down applications Quick release sealed valve or cowbell reject mechanisms available The new color touchscreen provides access to all critical functions and controls...

Open the catalog to page 6

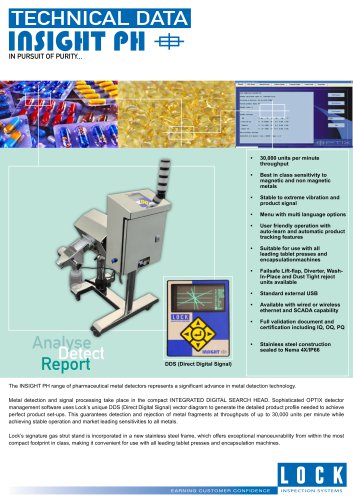

LOCK-PH for Pharmaceutical Provides inspection of tablets or capsules after the tablet press and de-duster process with the highest levels of sensitivity • Built upon IQ4 technology with 7” color touchscreen and user interface Provides the best in class sensitivity to magnetic and non-magnetic metals Compact polished stainless steel finish Reject options including Lift-flap, Diverter, Wash-in-Place and Dust Tight Certified with full IQ, OQ, PQ documentation IQ4: Improving the User Experience The 7” touchscreen on the IQ4 series of Metal Detectors features a new and updated user interface...

Open the catalog to page 7

Worldwide Locations Headquartered in the UK, LOMA SYSTEMS operates from several locations in the Americas, Europe and Asia. Across these sites LOMA conducts ongoing research and development, specialised manufacturing, sales and service support. Through a worldwide network of OEM and distributor partners, LOMA supplies and supports inspection equipment in over 100 other countries. Plzen, Czech Republic Farnborough, UK - Head Office Helmond, Netherlands Nantes, France Dinslaken, Germany Warsaw, Poland About LOMA SYSTEMS Established in 1969 in the UK, LOMA SYSTEMS designs, manufactures and...

Open the catalog to page 8All Loma Systems catalogs and technical brochures

-

IQ4 RUN-WET

4 Pages

-

CW3S Compact Checkweigher

2 Pages

-

Checkweigher for up to 60 kg

2 Pages

-

X-RAY INSPECTION

12 Pages

-

Super-Heavy Checkweighers

2 Pages

-

X5 XL X-ray Inspection

2 Pages

-

X5c X-ray Inspection

2 Pages

-

Gravity Fall Metal Detectors

2 Pages

-

X-Weigh Inspection Systems

2 Pages

-

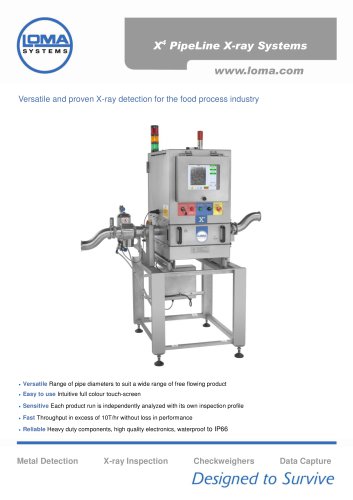

X 4 PipeLine X-ray Systems

2 Pages

-

IQ3 QuickShip

2 Pages

-

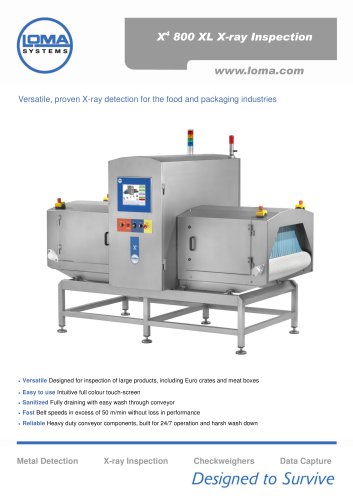

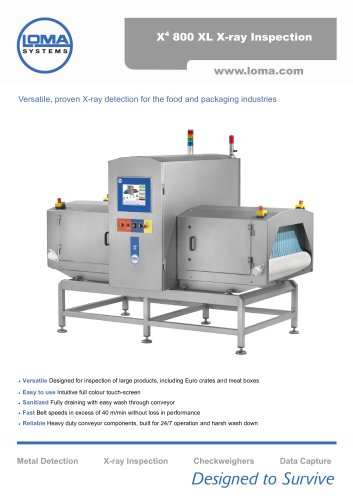

X4 800 XL X-ray Inspection

2 Pages

-

Data Capture Systems OPC

2 Pages

-

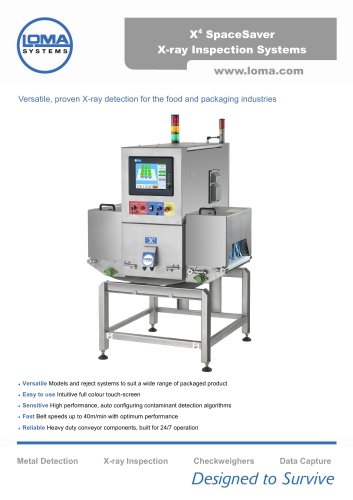

SpaceSaver X-Ray Inspection

2 Pages

-

60000 SH - Super HeavyWeight

2 Pages

-

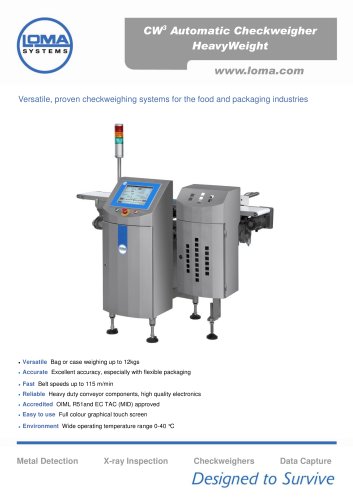

12000 H - Heavyweight

2 Pages

-

6000 MDL - Drag Link

2 Pages

-

6000 M - Mid Range

2 Pages

-

1500 L - LightWeight

2 Pages

-

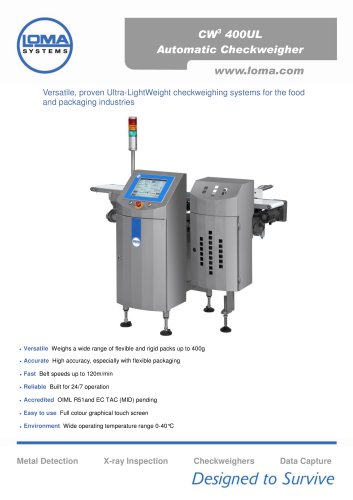

400 UL - Ultra LightWeight

2 Pages

-

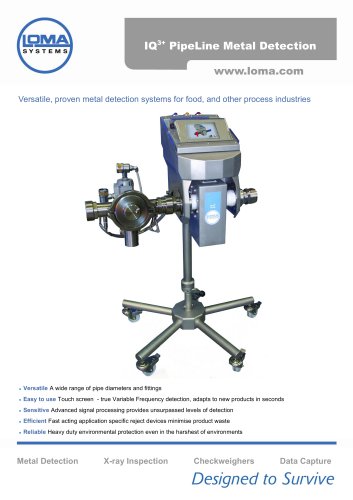

Pipeline Metal Detectors

2 Pages

Archived catalogs

-

Family Brochure

6 Pages

-

Entry Level X-ray Inspection

2 Pages

-

Pack X-ray Inspection

2 Pages

-

Combo Checkweighers

2 Pages

-

Mid Range Checkweighers

2 Pages

-

Free Fall Metal Detectors

2 Pages

-

Metal Detector Conveyors

2 Pages