Catalog excerpts

DOCK EQUIPMENT & INDUSTRIAL DOORS Industrial doors www.loading-systems.com

Open the catalog to page 1

Loading Systems

Open the catalog to page 2

Industrial doors

Open the catalog to page 3

We take care. Advanced Control Centre Door design Sectional overhead doors Fire doors Speed doors Industrial air curtains Strip curtains Renovation & replacement Service

Open the catalog to page 5

1. We take care. Loading Systems delivers total solutions for loading and unloading with the emphasis on ‘total’. As one of the European market leaders and pioneers in the field of loading and unloading, we manage the complete end to end process from consultancy, design, production, project management, installation and service. Our state-of-the-art R&D department, as well as our flexible regional manufacturing locations guarantee a market-orientated solution to cater for all your logistical needs. Managing Directors Ronald and Harald van Wijk and the Loading Systems Management Team. Pioneers...

Open the catalog to page 6

Safe and efficient Loading Systems organises the layout of your loading and unloading bays to ensure maximum safety and efficiency. Whether it involves the design, installation, commissioning or maintenance: your requirements are the starting point for each element of our services. It goes without saying that our products and services comply with the European Machinery Directive Guidelines and include CE-marking. All Loading Systems companies are certified in accordance with the valid national and international quality marks, such as ISO 9001:2000, VCA, Investors in People, and HACCP....

Open the catalog to page 7

2. Advanced d Control Cent Centre en With the Loading Systems Advanced Control Centre you can efficiently and pro-actively coordinate, monitor, control and manage vehicle traffic around your loading bays. The system is based on Dock Management, Facility Management, Service and Statistics & Reporting modules. Your loading and unloading systems, monitored 24/7

Open the catalog to page 8

The Advanced Control Centre Dock Management module offers live information on the status of all your loading bays. Vehicles can be allocated to a loading bay by making a real-time reservation at the loading bay from a remote location. As soon as the vehicle docks at a loading bay, you immediately see what is happening on the screen. The live status of the equipment at the loading bay is also made continuously visible, including information on whether the dock door is open or closed, or whether a dock leveller is or is not in use. As soon as the vehicle departs on completion of the loading...

Open the catalog to page 9

2. Advanced Control Centre 2.3 Service With the Advanced Control Centre Service module, your loading and unloading bay equipment is monitored 24/7. The Advanced Control Centre informs a Loading System specialist on any loading and unloading bay equipment breakdowns. Problems can immediately be analysed and solved, at times often remotely, which significantly reduces operational disruption to your loading and unloading activities. Maintenance Periodic maintenance guarantees maximum optimisation of your loading and unloading bay equipment. Based on measured usage, periodic maintenance can be...

Open the catalog to page 10

2. Advanced Control Centre The Advanced Control Centre Statistics & Reporting module allows you to optimise transport and flow of goods. With the Statistics & Reporting module you have the possibility to retrieve loading bay equipment usage rates, exact and average loading and unloading times, and the number of movements per loading and unloading bay. Data can be used effectively and efficiently to monitor and control your loading and unloading activity to optimise efficiency. The Advanced Control Centre is an easily accessible solution and is fully web-based. It only requires minimal...

Open the catalog to page 11

3. Door design The choice of door is influenced by a number of important factors; such as traffic volume, type of vehicle traffic, processing equipment and access control. At Loading Systems you have the possibility to adapt your doors completely to suit your own specific requirements, regardless of any changes in circumstances. There is for example a more cost-efficient design available; an improved door design generates substantially lower operating costs than a standard door. This is extremely beneficial to your operating cost efficiency.

Open the catalog to page 12

The right door at the right place can generate substantially lower operating costs The dimensions of industrial doors can greatly vary depending on the type of door required, for example : loading bay doors, drive-in/drive-through doors. A drive-in/drive-through door, or level access door, typically has a clearance of: Clearance dimensions drive-in/drive-through doors: Width: Height: * The lorry’s maximum head clearance plus a specified safety margin. The clearance of a loading bay door typically depends on factors such as: • The height of the platform. • The type of goods to be...

Open the catalog to page 13

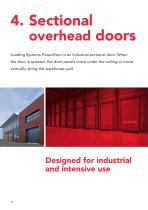

4. Sectional overhead doors Loading Systems PowerDoor is an industrial sectional door. When the door is opened, the door panels move under the ceiling or move vertically along the warehouse wall. Designed for industrial and intensive use

Open the catalog to page 14

Safety, durability, ease of use and optimal insulation The product is designed not to encroach into valuable warehouse space and further ensures that the door is optimally protected from damage. Loading Systems PowerDoor can be made bespoke to your own requirements by offering many variations in design, finishes, operational systems and installation options. User-friendliness and safety are our main priorities. Long life span Because overhead doors are often subjected to extreme weather conditions, Loading Systems ensures that our door panels are protected against corrosion and warping. All...

Open the catalog to page 15

4. Sectional overhead doors High insulation characteristics Loading Systems standard overhead door panels are designed with a 40 mm thickness which seamlessly close to ensure an insulation value in the highest classifications by CE standards. The insulation characteristics can significantly lower the energy consumption of any building, warehouse or similar facility when installed with Loading Systems PowerDoors. The polyurethane foam core between the high grade steel coil is also fire retardant and CFC-free. Aesthetics Loading Systems offers an extensive range of standard panel colours and...

Open the catalog to page 16All Loading Systems International catalogs and technical brochures

-

Dock equipment

72 Pages

Archived catalogs

-

Powerlift tables

2 Pages

-

Powerdoor industrial doors

2 Pages

-

Powershelter dockshelters

2 Pages

-

Corporate Brochure

2 Pages

-

DESIGNING A LOADING-DOCK

20 Pages