Catalog excerpts

For your most demanding applications, rely on Lippmann’s full line of versatile crushing equipment. Meticulously engineered to achieve the lowest cost per ton of material produced in aggregate, mining, and recycling, Lippmann offers best-in-class reliability at an outstanding value. From delivery to training to service and beyond, our expert team will help ensure your operation is always running at peak performance. No one in the crushing industry stands behind their product quite like Lippmann.

Open the catalog to page 2

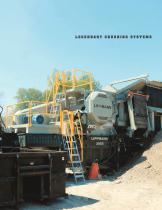

LEGENDARY CRUSHING SYSTEMS

Open the catalog to page 3

JAW CRUSHERS Applications: Primary Industries: Aggregate, Mining, Recycling Mounting: Portable Plant, Mobile Plant, Skid, Stationary, Bare Our world-renowned jaws lie at the core of Lippmann’s product offering and have been manufactured in Milwaukee, WI, since 1923. Fabricated with extraheavy ribbed steel plate construction, Lippmann jaw crushers have proven time and again they provide maximum strength, durability, and reliability at the lowest cost of ownership in the industry. Frames are stress-relieved before machining to ensure uniform heavy-duty strength and trouble-free operation on a...

Open the catalog to page 4

MOUNTING BOLT DIAMETER CRUSHER WEIGHT *Dimension denotes crusher mounting hole centers. 1 D imension is from bottom of mounting surface to top of feed side of crusher frame (Jaw can be mounted flat or tipped, drawing to confirm orientation is recommended). JAW CRUSHER CAPACITIES HYDRAULIC TOGGLE OR MANUAL TOGGLE PLATE OPTION GAPE X WIDTH Inches mm HP (Electric Drive Motor) MANUAL TOGGLE PLATE OPTION ONLY CLOSED SIDE SETTING (CSS) INCHES Inches mm STPH MTPH STPH MTPH STPH MTPH STPH MTPH STPH MTPH STPH MTPH STPH MTPH STPH MTPH STPH MTPH

Open the catalog to page 5

IMPACT CRUSHERS Applications: Primary, Secondary Industries: Aggregate, Mining, Recycling Mounting: Wheeled Plant, Tracked Plant, Skid, Stationary, Bare Proven in a variety of applications and materials, Lippmann impact crushers stand up to the most demanding aggregate, mining and recycling operations. Crush a wide range of materials like limestone, dolomite, gravel, basalt, copper reverts, concrete, and asphalt without losing strength or efficiency. Whether portable, stationary, or skid-mounted, these rugged impact crushers provide consistently high production at an incredible value. For...

Open the catalog to page 6

IMPACT CRUSHER DIMENSIONS A * Dimension denotes crusher feed opening. IMPACT CRUSHER CAPACITIES HP (Electric Drive Motor) MAXIMUM FEED SIZE CAPACITY LIMESTONE MINIMUM SETTING NUMBER OF HAMMER ROWS

Open the catalog to page 7

CONE CRUSHERS Applications: Secondary, Tertiary, Quaternary Industries: Aggregate, Mining Mounting: Portable Plant, Mobile Plant, Skid Lippmann cone crushers push the boundaries of industry performance and round out our crusher portfolio. A revolutionary combination of crusher speed, throw, and cavity design offers higher capacity and superior product quality for a wider range of applications. With high-material capacity and throughput, large stockpile capacity, and operator-friendly features, Lippmann cone crushers are ready to take on the heaviest of projects with unrivaled reduction...

Open the catalog to page 8

CONE CRUSHER CLEARANCE DIMENSIONS SIZE B - djustment ring A maximum diameters C - learance required for removing C countershaft assembly F - nside diameter of I feed hopper Clearance required for removing bowl assembly Clearance required for removing head assembly J - dditional upward travel of feed A hopper during clearing stroke K - Mounting hole location Main frame discharge opening diameter

Open the catalog to page 9

CONE CRUSHER CAVITY SELECTION STANDARD Crusher Size SHORT HEAD Extra Fine Extra Coarse Extra Fine Fine Extra Coarse Extra Fine Fine Extra Coarse 1 - he minimum setting is that at which the crusher will operate without causing ring bounce. T Depending on the crusher characteristics of the rock, this setting can change. 2 - Feed opening “B” is at a minimum setting “A.” 3 - Maximum feed size varies from 80 to 100% of “B” depending on machi

Open the catalog to page 10

CONE CRUSHER PRODUCTION GRADATION AND CAPACITIES PRODUCT GRADATION TABLE (% PASSING THROUGH SQUARE MESH DEPENDING ON THE SETTING) 1/4" / 6 4" / 100 CRUSHER CAPACITIES CLOSED SETTING Ton/hour 1 - Represents capacity through crusher based “instantaneous” product sample.

Open the catalog to page 11

3271 East Van Norman Avenue Cudahy, WI 53110 Lippmann-Milwaukee.com 800-648-0486 LM 0006-1 US

Open the catalog to page 12