Catalog excerpts

PORTABLE JAW CRUSHING PLANT THE 4248J-W IS YOUR BEST CHOICE FOR IN-PIT CRUSHING This jaw plant is designed for in-pit crushing, high capacity applications and provides unmatched production and reliability in the market. It features an options hammer and hopper extensions capable of handling large front end loaders or trucks and is specifically designed to handle 1000+ tons per hour making sure there is enough capacity in the hopper and conveyor to be able to obtain this. • An extra heavily ribbed steel frame-stress relieved after welding and before machining • One piece steel pitman • Heat-treated forged alloy steel eccentric shaft Oversized tapered roller bearings in both the pitman and frame. Tapered roller bearings exhibit a greater load carrying capacity compared to an equal sized spherical roller used in competitor’s machines • Manual toggle adjustment • Reversible manganese steel jaw dies and extensions • Bolt in replaceable toggle bearings • Manganese steel cheek plates • Two heavy-duty flywheels, one grooved for V-belts • Swing jaw barrel protector • Replaceable wear plate behind the swing jaw die & stationary jaw die • Automatic Oil Lubrication System which delivers a metered flow of filte

Open the catalog to page 1

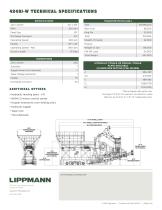

4 2 4 8 J - W TEC H N I C AL SPE CIFICATIONS SPECIFICATIONS Jaw Crusher Rear Axle Feed Size Discharge Conveyor Operating Speed Grizzly Length Total Weight Autolube Toggle Power Unit (optional) Taper Wedge (optional) HYDRAULIC TOGGLE OR MANUAL TOGGLE PLATE AVAILABLE [CLOSED SIDE SETTING (CSS) INCHES] Discharge Conveyor ADDITIONAL OPTIONS *1069-1178 *1176-1309 * Manual toggle plate option only. • ydraulic leveling jacks - (4) H See page 2-10 from the Lippmann Jaw Book for values 4248 can be set from 4” to 8” (14” toggle plate only). • NEMA 12-motor control center • Hopper extensions...

Open the catalog to page 2