Catalog excerpts

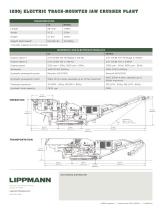

ELECTRIC TRACK-MOUNTED JAW CRUSHER PLANT THE 1200j POWERS HEAVY DUTY CRUSHING AND SAVINGS.

Open the catalog to page 1

Electric Track-Mounted Jaw Crusher Get a true edge on the job site with the 1200j electric heavy duty track-mounted jaw crusher, which strikes the perfect balance of reducing electric power operation costs while increasing reliability. With a 75" (1905mm) deep jaw chamber, this go-to crusher tackles the toughest applications in mining, aggregate, and recycling. Rely on the 1200j for smooth operation and maximum throughput as Lippmann engineers have optimized the material flow and jaw chamber design for high productivity. Hydraulic fold and wedge lock hopper, optional extensions High inertia...

Open the catalog to page 2

Power system includes choice of Tier 3 or Tier 4F/ Stage 5 engine for genset 55" (1397mm) belt with hydraulic adjustable angle for large stockpile capacity DSE control panel with line connections (on other side of machine) Deep 75" (1.91m) jaw chamber with single toggle design accommodates hard rock applications and large feed sizes. Also features closed side setting adjustment with hydraulic wedges. Double deck grizzly pre-screen featuring hydraulic fold and wedge lock hopper, and optional cassettes punch plate or fingers. The large gap between crusher discharge and main conveyor belt,...

Open the catalog to page 3

CLOSED SIDE SETTING (CSS) inches Crusher speed Crusher stroke Crusher drive Hydraulic V-belts Hydraulic V-belts Minimum opening Maximum opening Maximum feed size Crusher weight - bare Hydraulic wedges Hydraulic wedges Starter - includes unblock software

Open the catalog to page 4

Electric Power Decreases Costs, Increases Reliability THE L I PPM AN N E D G E Electric operation on select jaw plant models is the latest in a long line of Lippmann innovation since 1923. Designed with the customer in mind, these electric jaw crushers cost less to run while taking reliability to new levels. • Line power connection standard • onnect to line power or on-board generator C • lectrical connections provide simplified troubleshooting E • eliable 12" (305mm) DSE control panel R • ush-button control of jaw, track, and feeder functions P SAFETY AT EVERY STEP, STANDARD SAFETY...

Open the catalog to page 5

12 0 0j E L E C T R I C T R AC K - M OU NTED JAW CRU SHER PLANT TRANSPORTATION US Weight (Estimated)* *includes magnet and dirt conveyor POWERUNIT AND ELECTRICS/HYDRAULICS US Engine speed Hydraulic powerpack pump Hydraulic powerpack motor WEG 74 hp 4 pole, operates up to 121 hp maximum WEG 55kW 4 pole, operates up to 90kW maximum Flowrate maximum Hydraulic tank capacity 12'-7.5" (3848mm) AUTHORIZED DISTRIBUTOR 3271 East Van Norman Avenue Cudahy, WI 53110 Lippmann-Milwaukee.com 800-648-0486

Open the catalog to page 6