Catalog excerpts

Disclaimer: Information presented in this brochure is for informational purposes only. Link Engineering Company reserves the right to make changes, alterations and substitutions to the machines, components or other information presented in this brochure without prior notice. For the latest information contact Link Engineering Company. Equipment pictured in this brochure may be shown with safety equipment removed or disabled for purposes of illustration. Equipment must never be operated with safety equipment removed or disabled. Single Source for Testing Equipment and Services Across America and Around the World Asia œ Europe œ North America œ South America Link Engineering Company +1-734-453-0800 www. linkeng.com The LINK Model 3100 SAE No. 2 Test Stand is designed to perform standard SAE and developmental wet friction testing on clutch and band systems utilizing production hardware and fluids. This machine incorporates the latest technology for optimal testing versatility and correlation to actual powertrain operating conditions. The Model 3100 is an inertia dynamometer in which the kinetic energy of a rotating mass is dissipated by the clutch or band being tested. Torque is measured via dual load cells mounted on dual torque arms attached to the test head. The test head is mounted on dual back-to-back precision angular bearings attached to the machine base for reduced vibration at high speed operation. Test head piston apply force is generated by pneumatic pressure or an optional hydraulic system. Test fluid is supplied to the test head with a recirculating hydraulic system and fluid temperature is controlled with a system of in-line and tank heaters as well as water jackets in the head for cooling. The Model 3100 is designed with a 75 kw (100 hp) variable speed AC motor, providing the capability for inertia simulation (I-SIM). This feature supports continuous slip testing, improved torque control, and an unlimited range of inertia. The variable speed AC motor along with I-SIM capability not only results in increased test efficiency by reducing inertia disc changes, but also provides the ability to simulate actual shift characteristics during the test sequence. The Model 3100 also uses a 22 kw (30 hp), high torque 1132 Nm (835 lb-ft), bi-directional AC motor coupled to the main drive motor via a helical bevel gearbox, for low speed (0-300 rpm) continuous slip operation and static breakaway friction testing. The Model 3100 system controls are designed to provide flexible test programmability. Advanced features of ProLink© controls offer operator dependent or fully automatic unattended operation. All primary operating machine functions are performed at the console, including selection of test parameters, control modes, display of pertinent data, and monitoring of all test functions. Wet Friction Test Stand Model 3100 Machine Capabilities • Friction material & ATF friction characterization • Automatic transmission clutches • Automatic transmission bands • Automatic transmission torque converter clutches • Manual transmission synchronizer rings

Open the catalog to page 1

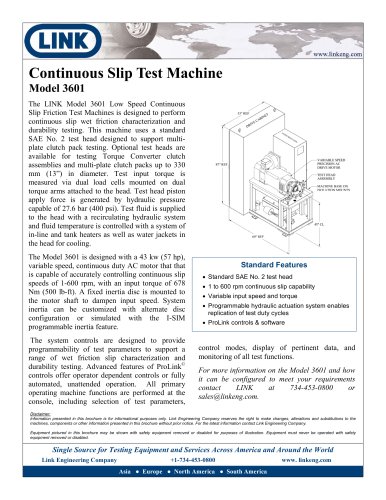

Disclaimer: Information presented in this brochure is for informational purposes only. Link Engineering Company reserves the right to make changes, alterations and substitutions to the machines, components or other information presented in this brochure without prior notice. For the latest information contact Link Engineering Company. Equipment pictured in this brochure may be shown with safety equipment removed or disabled for purposes of illustration. Equipment must never be operated with safety equipment removed or disabled. Single Source for Testing Equipment and Services Across America...

Open the catalog to page 2All Link Engineering catalogs and technical brochures

-

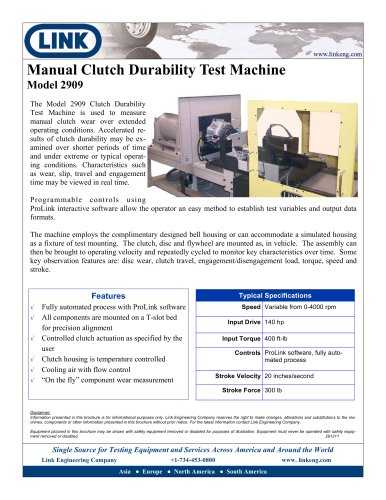

friction testing machine

2 Pages

-

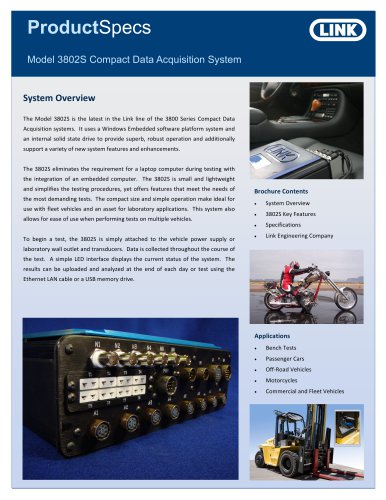

3802S

4 Pages

-

Wet Friction Clutch Testing

4 Pages

-

Clutch Burst Machine

2 Pages

-

FAST Dry Friction Test Stand

2 Pages