Catalog excerpts

TestSpecs Wet Friction Clutch Testing for the Transportation Industry Link Engineering – Proven Testing Solutions Link Engineering’s 75 years of experience developing highly]sophisticated test systems, coupled with its network of testing facilities and resources around the world, makes Link Engineering Company your preferred partner for test systems and independent testing services. Whether it is product benchmarking, product library and technical specification development, formulation and process refinement, or product monitoring, the use of international standards allows a cost]effective and transparent process to simplify the total test cycle and enables repeatable and reliable engineering and business decisions. With faster and higher]than]ever demands on product performance, durability, and comfort through the life of the product and an emphasis on Total Life Cycle Cost optimization, routine and standard laboratory testing provides the best approach for design, manufacturing, application, and sales engineers. Worldwide Testing Resources Link Engineering Company, with headquarters in Plymouth, MI and testing facilities in the United States, Korea, and Germany, designs, fabricates and operates automated test systems ranging from motorcycles to aircraft and from brake to transmission systems. Regional sales and service offices in Brazil, China, Korea, Japan, India and Europe extend our global operation to allow timely and direct discussion with the customer. Brochure Contents „hƒn Link Engineering Company „hƒn Typical Wet Clutch System Tests „hƒn Laboratory Testing „hƒn Other Testing Systems and Services

Open the catalog to page 1

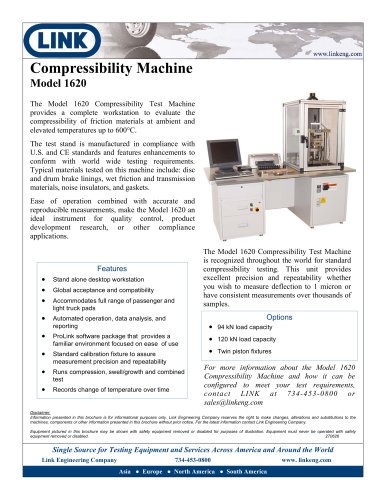

Mechanical and Physical Properties The Link Metrology Lab has full capability for product measurement and analysis including dimensional, surface finish and high power photography. Link has friction material compressibility test equipment, capable of testing at elevated temperatures up to 600° C and deflection measurement in the 1 micron range. Link also has access to test lab facilities with advanced laboratory technology including micrographic, TGA, SEM and analytical design FEA capability. Client Directed or Developmental Procedures Link performs specialized friction testing in...

Open the catalog to page 2

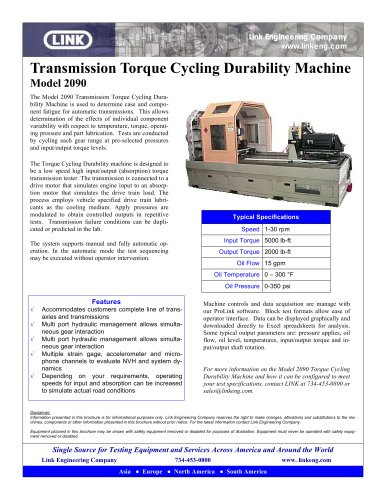

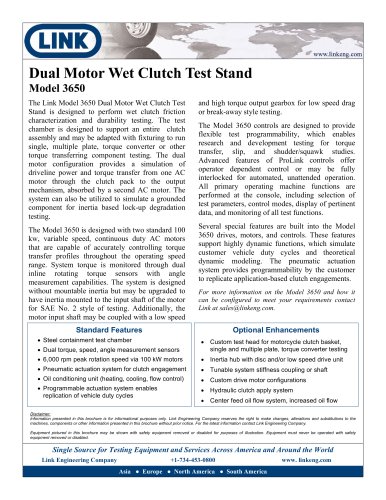

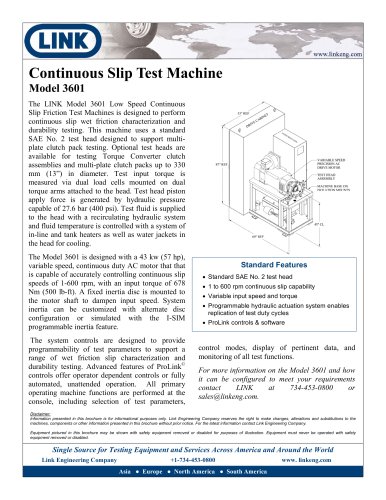

Component Performance and Durability Testing Link Utilizes SAE No. 2 & TO]4 Wet Friction Test Stands to Perform Standard & Customer Proprietary Protocols SAE J2487 – Wet Friction Stepped Power Test: Automatic Transmission Clutch Pack Performance ]Tests are run at 3600 rpm engagement speeds at incremental Inertias to determine friction characteristics as a function of power input. SAE J2488 – Wet Friction Stepped Power Test: Automatic Transmission Clutch Pack Performance ] Tests are run at 6000 rpm engagement speeds at incremental Inertias to determine friction characteristics as a function...

Open the catalog to page 3

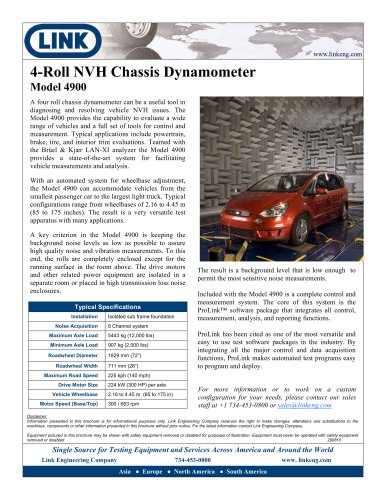

Transmission and Driveline Performance and Durability Testing Driveline System Performance: Driveline system performance tests are used to assess transmission and driveline component function and system interactions. Link has several test facilities available for this type of testing. Inertia dynamometers can be adapted for testing of automatic transmission, manual clutch, or differential systems. Vehicle testing can be performed on the 4]roll chassis dynamometer at the ARC facility in Canton, Michigan or at proving ground facilities located in Michigan, Ohio and Arizona. Driveline System...

Open the catalog to page 4All Link Engineering catalogs and technical brochures

-

friction testing machine

2 Pages

-

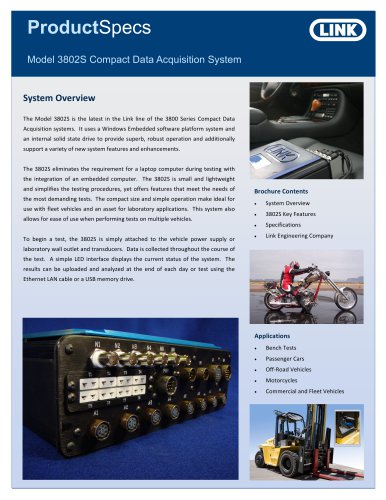

3802S

4 Pages

-

Clutch Burst Machine

2 Pages

-

FAST Dry Friction Test Stand

2 Pages